- 5 -

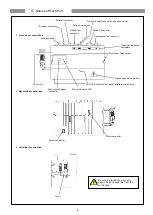

1. Installation of the motor

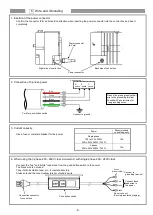

Open three 9mm holes on the table as seen from

the above. Install the motor securely using the

installation bolts, washers, spring washers and

nuts.

The installation bolts, etc., are included with the

motor as accessories.

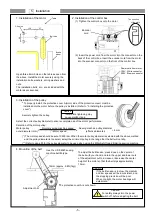

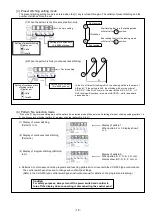

3. Installation of the pulley

*

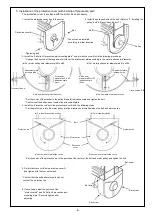

To properly install, the protective cover A (motor side of the protective cover) must be

installed onto the motor before the pulley is installed. (Refer to "5. Installing the protective

cover”.)

Securely tighten the pulley

.

Select the correct pulley diameter to ensure complete use of the motor performance.

Selection of the motor pulley:

Motor pulley

outer diameter (mm)

(*) The motor speed should be set at 3,600rpm. When the motor pulley diameter is selected with the above method

and the pulley diameter is too small, select the minimum pulley in the range that the belt will not slip.

(**) Refer to page 20 for the pulley diameter to be used when using the Mitsubishi thread trimming sewing machine.

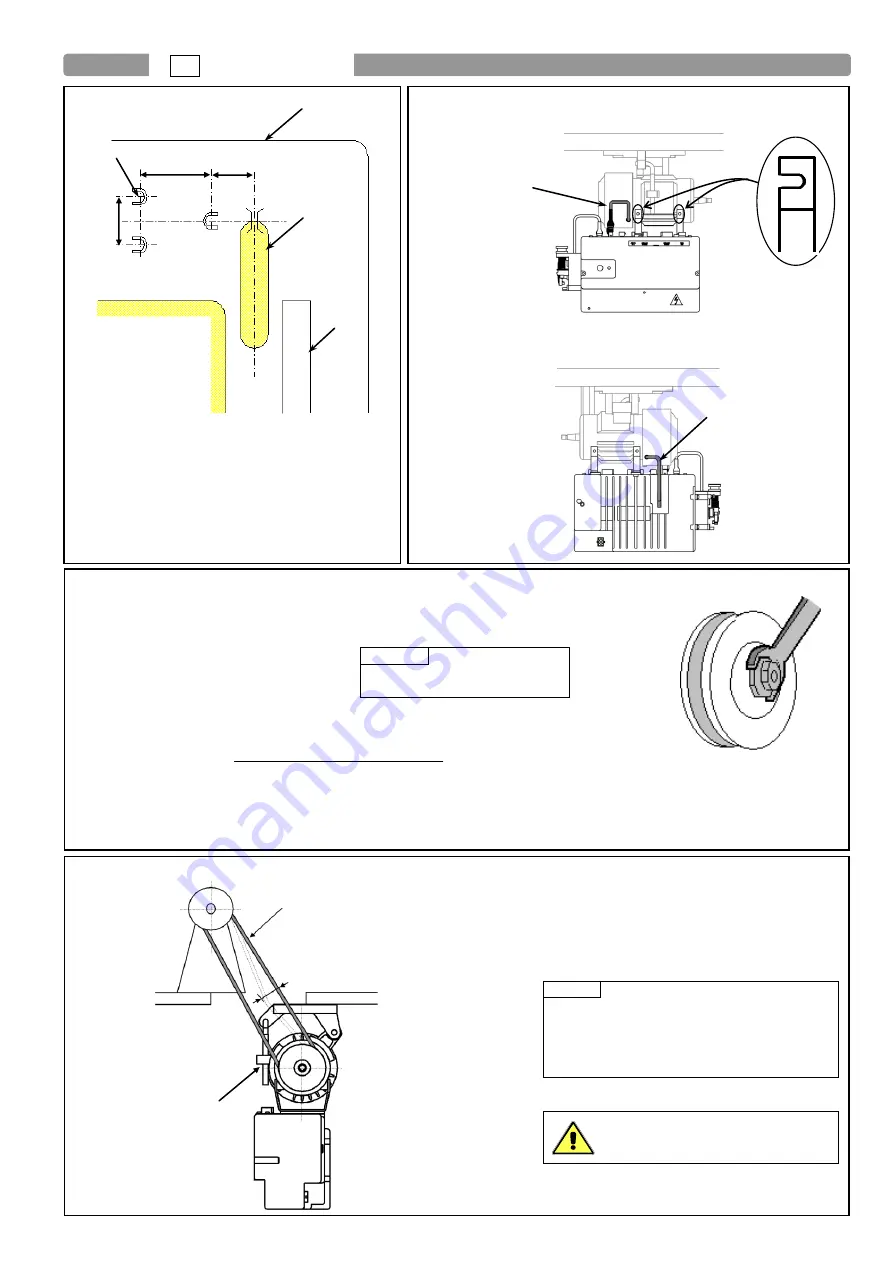

4. Mounting of the belt

To adjust the belt tension, press down on the center of

the belt with your hand, and turn the upper and lower nuts

of the adjustment nut to increase or decrease the center

height of the motor so that the belt dips approximately

15mm.

5 Installation

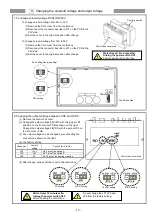

2. Installation of the control box

(1) Tighten the control box onto the motor.

(2) Insert the power cord from the motor into the connector on the

back of the control box. Insert the encoder cord from the motor

into the encoder connector on the front of the control box.

If the belt tension is too low, the medium

and low speeds will be inconsistent, and

the stopping precision will be poor.

When too tight, the motor bearings will

deteriorate.

Caution

For safety always turn the power

switch off, before adjusting the belt.

Caution

Use the JIS K6323 sewing

machine belt M-type.

15mm (approx. 9.8N(1kg))

Adjustment nut

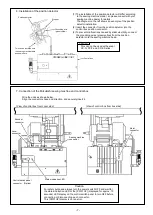

Table

Belt hole

Bobbin

winder

66

3-9 holes

159

57

Encoder

cord

Power cord from motor

100V : White connector

200V : Brown connector

T

he protective cover A is not shown.

Normal sewing machine speed

(

*

)

Motor speed

Sewing machine pulley diameter

(effective diameter)

= x + 5 mm

Incomplete tightening may

cause malfunctions.

Caution

The direction

of the plate