2-8

Installation

2Unpacking to Installation

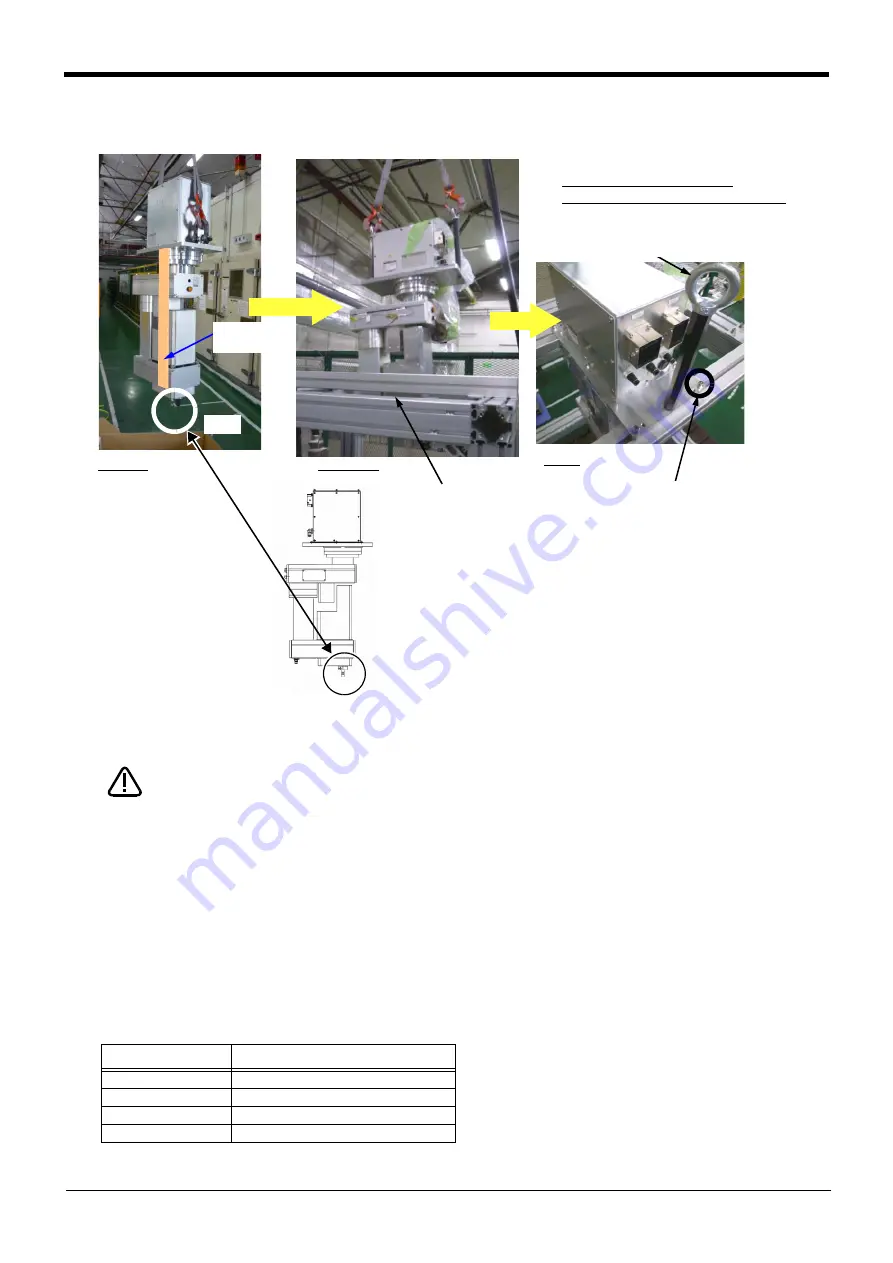

2.2.2 Transportation procedures(Transporting with a crane)

Fig.2-2 : Transportation of robot arm

The transportation procedure is shown below. Transport the robot with careful of safety, referring to

Transport by using the crane with fixing plate (7) still being installed is necessary.

Transport carefully so that the robot may not tilt by using two wires. Take care suffi

-

ciently not to give the interference and the shock with the installation stage etc.,

1) Transport the robot by the crane from the condition which unpacking completed to the fixing position of

installation stage <8>.

2) Fixing the robot by four installation bolts <9> (attached) certainly to installation stage <8>.

3) Remove hanging tools (two places) <4> after installation. Loosen the screw (M5 x 4, M4x1) fixing the fixing

plate <7>, and remove the fixing plate <7>. Also remove the nut for T slots. Fixing plate <7>, and fixing

screws and hanging tools <4> are needed at secondary transportation. Please keep them with care.

Transportation is complete above.

The transportation posture is shown in

Table 2-2 : Transportation posture

Axis

RH-3SDHR3515

J 1

0 deg.

J 2

0 deg.

J 3

Note1)

Note1) Because if the J3 axis is lowered the shaft juts

danger, be sure to specified posture at transport.

-569.5mm (Upper end)

J 4

Not fixed

Mass

RH-3SDHR3515: Approx. 24kg

RH-3SDHR3512C/3512W: Approx. 28kg

Note)

Note) Be cautious of interference

at the end of the shaft.

Hoisting

Transport

<8> Installation stage

Install

<4> Hanging tools (two places)

<9> Installation bolt, Nut

(four places)

<7> Fixing

plate

CAUTION