5-76

Maintenance and inspection procedures

5Maintenance and Inspection

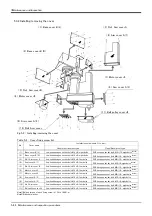

(2) Lubrication method

1) The positions of lubrication ports are shown in the

. Move the robot to the posture in which it can

supply the grease easy.

2) Refer to

Page 66, "5.3.2 Installing/removing the cover"

, and remove the covers necessary.

3) Insert the grease shown in

using a grease gun from the lubrication grease nipple.

4) Install the covers with the removal procedure in reverse.

Use manual grease gun, and inject grease with pressure 0.03Mpa or less. Do not use

the grease gun, which derived by the factory air presser to avoid injecting by too high

pressure.

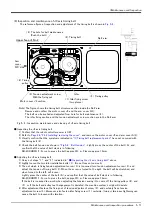

(3) Lubrication method to the J1, J2 axis

1) Refer to

Page 66, "5.3.2 Installing/removing the cover"

, and remove the covers necessary.

2) Insert the grease shown in

using a grease gun from the lubrication grease nipple. Add only the

specified amount of grease. Adding excess grease may cause grease to leak.

3) The J1 axis has the grease nipple and the timing belt in the near position. Although the timing belt is using the

oil-resistant belt, if the grease adheres, please wipe it off.

4) Install the covers with the removal procedure in reverse.

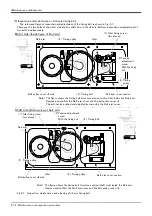

(4) Lubrication method to the shaft

1) Refer to

Page 66, "5.3.2 Installing/removing the cover"

," remove the motor cover J3.

2) Wipe the old grease off the shaft. At this time, wipe off the grease that has been scattered inside the motor

cover J3 and the bracket attached vertically to the shaft fastening area.

3) Apply the specified amount of grease to the shaft. If too much grease is applied, grease may get scattered

all over inside of the No. 2 arm. If the grease reaches the timing belt inside the No. 2 arm, the timing belt

may deteriorate prematurely.

4) Install the covers with the removal procedure in reverse.

CAUTION