CONTENTS

1. PRODUCT SPECIFICATIONS........................................................................................ 2

2. OUTER DIMENSIONS .................................................................................................... 3

3. EXTERNAL VIEW, PARTS AND DISPLAY SECTION................................................... 3

4. NAMES AND FUNCTIONS OF PARTS....................................................................... 4 ~ 8

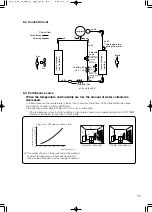

5. TECHNICAL POINTS................................................................................................... 9 ~ 11

6. MAINTENANCE ......................................................................................................... 12 ~ 13

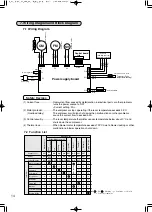

7. WIRING DIAGRAM AND BLOCK DIAGRAM

7.1 Wiring Diagram....................................................................................................... 14

7.2 Function List ....................................................................................................... 14 ~ 16

7.3 Timing Charts ..................................................................................................... 17 ~ 19

7.4 General Block Diagram ...................................................................................... 20 ~ 21

8. TROUBLESHOOTING PROCEDURE

8.1 Troubleshooting flowchart ................................................................................. 22 ~ 23

8.2 Key Component Check Procedures ....................................................................... 24

8.3 Error Indications and Corrective Actions ............................................................... 24

8.4 Self-Test Program and Execution Procedure ........................................................ 25

9. DISASSEMBLY AND REASSEMBLY HINTS .......................................................... 26 ~ 28

9.1 Disassembly Procedures ....................................................................................... 26

10. CONTINUOUS WATER DRAINAGE ............................................................................. 29

PARTS CATALOG .......................................................................................................... 30 ~ 37

11. TROUBLESHOOTING ............................................................................................... 38 ~ 39

PRECAUTIONS ............................................................................................................... 40 ~ 42

ADVANCED AND EVER ADVANCING

MITSUBISHI ELECTRIC

DEHUMIDIFIER

2005

SERVICE MANUAL

MJ-E16V-S1

Model

Sold from 2005

No.MJW-0502A