1. FUNCTIONS AND CONFIGURATION

1 - 17

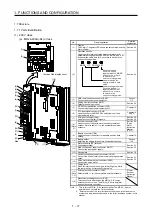

1.7 Structure

1.7.1 Parts identification

(1) 200 V class

(a) MR-J4-200A(-RJ) or less

No. Name/Application Detailed

explanation

(1)

Display

The 5-digit, 7-segment LED shows the servo status and the

alarm number.

Section 4.5

(2)

Operation section

Used to perform status display, diagnostic, alarm, and

parameter setting operations. Push the "MODE" and "SET"

buttons at the same time for 3 s or more to switch to the

one-touch tuning mode.

Used to set data.

Push this button

together with the "MODE"

button for 3 s or more

to switch to the

one-touch tuning mode.

MODE UP DOWN SET

Used to change the

display or data in each

mode.

Used to change the mode.

Push this button

together with the "SET"

button for 3 s or more

to switch to the

one-touch tuning mode.

Section 4.5

(3)

USB communication connector (CN5)

Connect with the personal computer.

Section

11.7

(4)

Analog monitor connector (CN6)

Outputs the analog monitor.

Section 3.2

(5)

RS-422 communication connector (CN3)

Connect with the personal computer, etc.

Chapter 14

(6)

STO input signal connector (CN8)

Used to connect the MR-J3-D05 safety logic unit and

external safety relay.

Chapter 13

App. 5

(7)

I/O signal connector (CN1)

Used to connect digital I/O signals.

Section 3.2

Section 3.4

(8)

(Note

2)

Encoder connector (CN2)

Used to connect the servo motor encoder or external

encoder. Refer to table 1.1 for the compatible external

encoders.

Section 3.4

"Servo

Motor

Instruction

Manual

(Vol. 3)"

(9)

Battery connector (CN4)

Used to connect the battery for absolute position data

backup.

Chapter 12

(10)

Battery holder

Install the the battery for absolute position data backup.

Section

12.2

(11)

Protective earth (PE) terminal

Grounding terminal

(12)

Main circuit power supply connector (CNP1)

Connect the input power supply.

Section 3.1

Section 3.3

(13) Rating plate

Section 1.6

(14)

Control circuit power supply connector (CNP2)

Connect the control circuit power supply and regenerative

option.

(15)

Servo motor power output connector (CNP3)

Connect the servo motor.

Section 3.1

Section 3.3

(16)

Charge lamp

When the main circuit is charged, this will light up. While

this lamp is lit, do not reconnect the cables.

(17)

(Note

1, 2)

External encoder connector (CN2L)

Refer to table 1.1 for the compatible external encoders.

"Linear

Encoder

Instruction

Manual"

Inside of the display cover

MODE

UP

DOWN

SET

(1)

(2)

(4)

(12)

(14)

(13)

(17)

Side

(9)

(5)

(6)

(7)

(16)

(15)

(8)

(3)

(18)

(10)

(11)

(18)

Manufacturer setting connector (CN7)

This connector is attached on the MR-J4-_A-RJ servo

amplifier, but not for use. The MR-J4-_A servo amplifier

does not have this connector.

Note 1. This is for the MR-J4-_A-RJ servo amplifier. The MR-J4-_A servo

amplifier does not have the CN2L connector.

2. "External encoder" is a term for linear encoder used in the linear servo

system and load-side encoder used in the fully closed loop system in this

manual.

Summary of Contents for MR-J4-100A

Page 9: ...A 8 MEMO ...

Page 61: ...1 FUNCTIONS AND CONFIGURATION 1 44 MEMO ...

Page 67: ...2 INSTALLATION 2 6 MEMO ...

Page 137: ...3 SIGNALS AND WIRING 3 70 MEMO ...

Page 261: ...6 NORMAL GAIN ADJUSTMENT 6 24 MEMO ...

Page 291: ...7 SPECIAL ADJUSTMENT FUNCTIONS 7 30 MEMO ...

Page 299: ...8 TROUBLESHOOTING 8 8 MEMO ...

Page 319: ...9 OUTLINE DRAWINGS 9 20 MEMO ...

Page 461: ...12 ABSOLUTE POSITION DETECTION SYSTEM 12 36 MEMO ...

Page 511: ...14 COMMUNICATION FUNCTION 14 38 MEMO ...

Page 559: ...16 USING A DIRECT DRIVE MOTOR 16 20 MEMO ...

Page 583: ...17 FULLY CLOSED LOOP SYSTEM 17 24 MEMO ...

Page 621: ...APPENDIX App 38 ...

Page 639: ......