APPENDIX

App. - 32

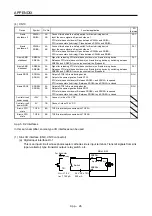

App. 5.9 LED display

I/O status, malfunction and power on/off are displayed with LED for each A-axis and B-axis.

LED

LED Description

Column A Column B

SRES

Monitor LED for start/reset

Off: The start/reset is off. (The switch contact is opened.)

On: The start/reset is on. (The switch contact is closed.)

SDI1

Monitor LED for shut-off 1

Off: The shut-off 1 is off. (The switch contact is closed.)

On: The shut-off 1 is on. (The switch contact is opened.)

SDI2

Monitor LED for shut-off 2

Off: The shut-off 2 is off. (The switch contact is closed.)

On: The shut-off 2 is on. (The switch contact is opened.)

TOF

Monitor LED for STO state

Off: Not in STO state

On: In STO state

SDO1

Monitor LED for SDO1

Off: Not in STO state

On: In STO state

SDO2

Monitor LED for SDO2

Off: Not in STO state

On: In STO state

SW

Monitor LED for confirming shutdown delay setting

Off: The settings of SW1 and SW2 do not match.

On: The settings of SW1 and SW2 match.

FAULT

FAULT LED

Off: Normal operation (STO monitoring state)

On: Fault has occurred.

A-axis B-axis

POWER

Power supply

Off: Power is not supplied to MR-J3-D05.

On: Power is being supplied to MR-J3-D05.

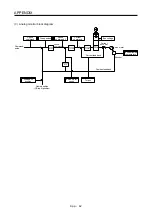

App. 5.10 Rotary switch setting

Rotary switch is used to shut off the power after control stop by SS1 function.

Set the delay time for STO output after STO shut off switch is pressed. Set same setting for SW1 and SW2,

and set the rotary switch setting according to the delay time in the table below.

Setting cannot be changed while power is on. Notify users that setting cannot be changed by putting a seal

or by another method so that end users will not change the setting after the shipment.

0 to F in the following table is the set value of the rotary switches (SW1 and SW2).

Rotary switch setting and delay time at A/B-axis [s]

B-axis

0 s

1.4 s

2.8 s

5.6 s

9.8 s

30.8 s

0

s 0 1 2 - 3 4

1.4

s - 5 - 6 7

2.8 s

8 - 9 A

A-axis

5.6 s

- B C

9.8

s

D E

30.8

s

F

Summary of Contents for MR-J4-100A

Page 9: ...A 8 MEMO ...

Page 61: ...1 FUNCTIONS AND CONFIGURATION 1 44 MEMO ...

Page 67: ...2 INSTALLATION 2 6 MEMO ...

Page 137: ...3 SIGNALS AND WIRING 3 70 MEMO ...

Page 261: ...6 NORMAL GAIN ADJUSTMENT 6 24 MEMO ...

Page 291: ...7 SPECIAL ADJUSTMENT FUNCTIONS 7 30 MEMO ...

Page 299: ...8 TROUBLESHOOTING 8 8 MEMO ...

Page 319: ...9 OUTLINE DRAWINGS 9 20 MEMO ...

Page 461: ...12 ABSOLUTE POSITION DETECTION SYSTEM 12 36 MEMO ...

Page 511: ...14 COMMUNICATION FUNCTION 14 38 MEMO ...

Page 559: ...16 USING A DIRECT DRIVE MOTOR 16 20 MEMO ...

Page 583: ...17 FULLY CLOSED LOOP SYSTEM 17 24 MEMO ...

Page 621: ...APPENDIX App 38 ...

Page 639: ......