- 38 -

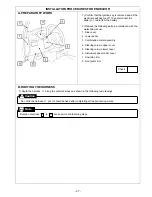

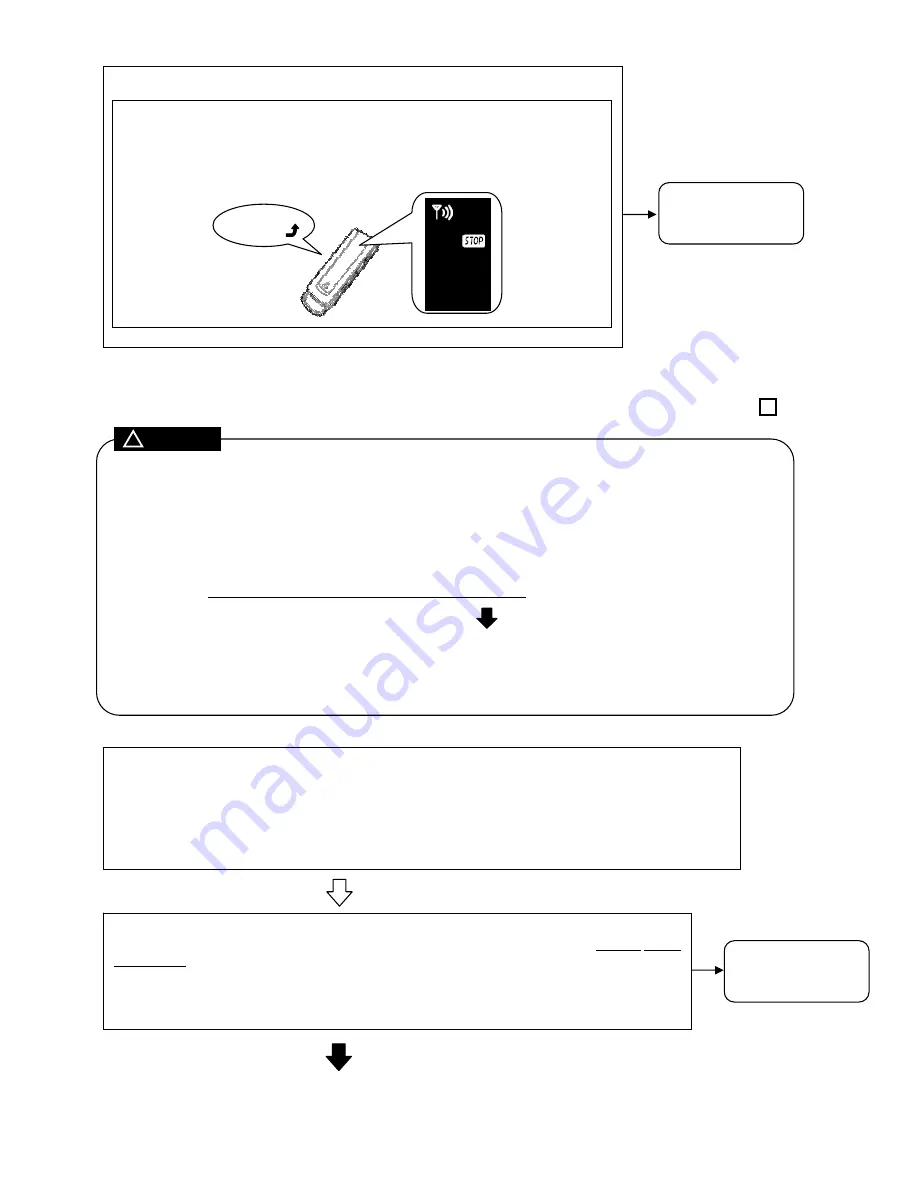

2) Perform the engine stop operation.

(2) Registration of the remote controller

Connect the (-) terminal of the vehicle's battery and perform the registration in the following procedure.

Beep

①

Push Stop SW for 1 seconds or more.

→

Buzzer sounds, and

Transmission, Stop Mark

lights approx. 3 seconds.

Go to

Troubleshooting A.

NG

Check

-The engine starter cannot function unless the remote controller is registered correctly.

- This procedure requires the keyless-entry key registered to the vehicle.

- Some steps of this procedure must be performed within the limited time. Be sure to understand this

procedure fully before starting the work.

If the required operation have not finished in a specified time,

the buzzer of the ECU will beep three times.

In such case, retry the registration procedure from the beginning.

The step that has a time limit is shown by a black arrow " ".

- The remote controller will not be registered if the procedure is not performed in the correct way. In such

case, disconnect the (-) terminal of the vehicle's battery once and then retry the registration procedure

from the beginning.

Caution

!

1) Set the vehicle in the following condition.

- Open the hood.

- Close all doors (including backdoor and trunk lid). (The worker should get in the vehicle.)

- Remove the ignition key from the ignition key cylinder.

2) Insert the ignition key into the key cylinder.

Turn the key from LOCK (OFF) to ACC to LOCK (OFF).Repeat this operation 5 times within

10 seconds.

When the key is finally returned to the LOCK(OFF) position after the above operation, the

buzzer of the ECU beeps once. If the buzzer sounds once, remove the key.

NG

Go to

Troubleshooting B.

OK

Summary of Contents for MZ360360EX

Page 6: ... 6 ...

Page 7: ... 7 ...

Page 16: ... 16 ...

Page 17: ... 17 ...

Page 28: ... 28 ...

Page 29: ... 29 ...

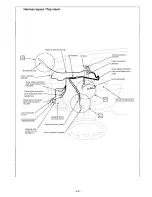

Page 42: ... 42 Circuit Diagram ...

Page 43: ... 43 ...

Page 44: ... 44 Troubleshooting P 38 step 2 ...

Page 45: ... 45 P 38 step 2 3 ...

Page 46: ... 46 P 41 step 3 3 ...

Page 47: ... 47 P 51 terminal No 3 P 51 ...

Page 48: ... 48 P 51 P 51 terminal No 13 ...

Page 49: ... 49 P 51 terminal No 24 P 51 terminal No 18 ...

Page 50: ... 50 ...