11

4.1 Overcurrent-Trip Characteristics (Delay

Tripping)

Tripping times for overcurrents of 130 and 200% of

rated current are given in Table 4.1, assuming ambi-

ent temperatures of 40

°

C, a typical condition inside

of panelboards. The figures reflect all poles tested to-

gether for 130% tripping, and 105% non-tripping.

Within the range of the long-delay-element (thermal

or hydraulic) operation, tripping times are substan-

tially linear, in inverse relationship to overcurrent mag-

nitude.

The tripping times are established to prevent ex-

cessive conductor-temperature rise; although times

may vary among MCCBs of different makers, the lower

limit is restricted by the demands of typical loads: tung-

sten-lamp inrush, starting motor, mercury-arc lamps,

etc. The tripping characteristics of Mitsubishi MCCBs

are established to best ensure protection against ab-

normal currents, while avoiding nuisance tripping.

4.1.1 Ambient Temperature and Thermal Tripping

Fig. 4.1 is a typical ambient compensation curve

(curves differ according to types and ratings), show-

ing that an MCCB rated for 40

°

C ambient use must

be derated to 90% if used in a 50

°

C environment. In

an overcurrent condition, for the specified tripping time,

tripping would occur at 180% rated current, not 200%.

At 25

°

C, for the same tripping time, tripping would

occur at 216%, not 200%.

4.1.2 Hot-State Tripping

The tripping characteristics described above reflect

“cold-state tripping” – i.e., overloads increased from

zero – and the MCCB stabilized at rated ambient. This

is a practical parameter for most uses, but in intermit-

tent operations, such as resistance welding, motor

pulsing, etc., the “hot state” tripping characteristic must

be specified, since over-loads are most likely to oc-

cur with the MCCB in a heated state, while a certain

load current is already flowing.

Where the MCCB is assumed to be at 50% of rat-

ing when the overload occurs, the parameter is called

the 50% hot-state characteristic; if no percentage is

specified, 100% is assumed. Hot-state ratings of 50%

and 75% are common.

4.2 Short-Circuit Trip Characteristics (In-

stantaneous Tripping)

For Mitsubishi MCCBs with thermal-magnetic trip units

the instantaneous-trip current can be specified inde-

pendently of the delay characteristic, and in many

cases this parameter is adjustable offering consider-

able advantage in coordination with other protection

and control devices. For example, in coordination with

motor starters, it is important to set the MCCB instan-

taneous-trip element at a lower value than the fusing

(destruction) current of the thermal overload relay

(OLR) of the starter.

For selective tripping, it must be remembered that

even though the branch-MCCB tripping time may be

shorter than the total tripping time of the main MCCB,

in a fault condition the latter may also be tripped be-

cause its latching curve overlaps the tripping curve of

the former. The necessary data for establishing the

required compatibility is provided in the Mitsubishi

MCCB sales catalogues.

The total clearing time for the “instantaneous” trip-

ping feature is shown in Fig. 4.3; actual values differ

for each MCCB type.

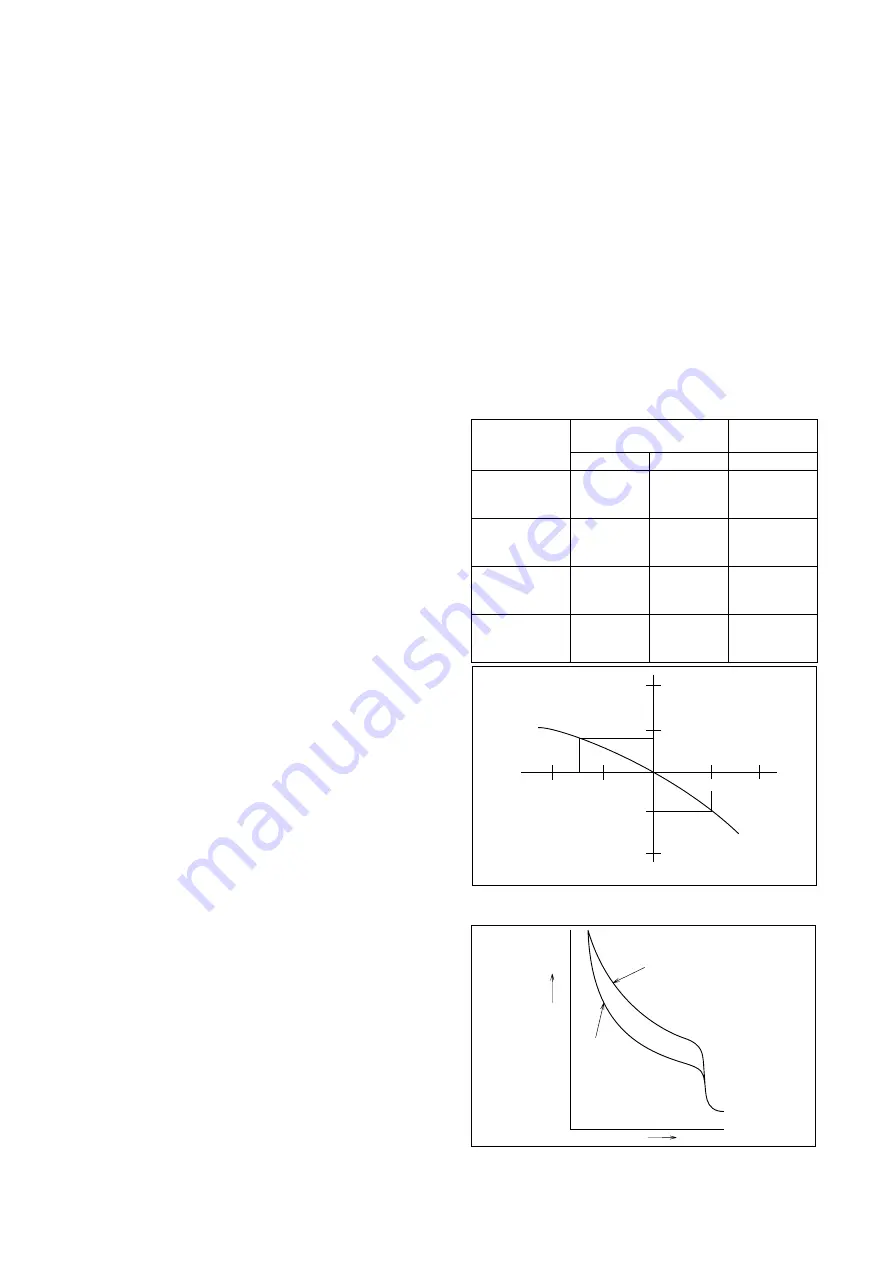

Table 4.1 Overcurrent Tripping Times

Rated current

(A)

30 or less

31~63

64~100

101~250

251~400

401~630

631~800

801~1000

1001~1250

1251~1600

1601~2000

2001~4000

Tripping time

(minutes, max.)

200%

8.5

4

8.5

8

10

12

14

16

18

20

22

24

130%

60

60

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

60

60

120

105%

Non-Tripping time

(minutes, max.)

20

25

Ambient temperature (

:

)

% rating compensation

30

40

110

108

100

50

60

90

80

120

Fig. 4.1 Typical Temperature-Compensation Curve

Cold state

Operating time

Current

Hot state

Fig. 4.2 Hot-State-Tripping Curve

4. CHARACTERISTICS AND PERFORMANCE