GDI ±

Troubleshooting

13A-66

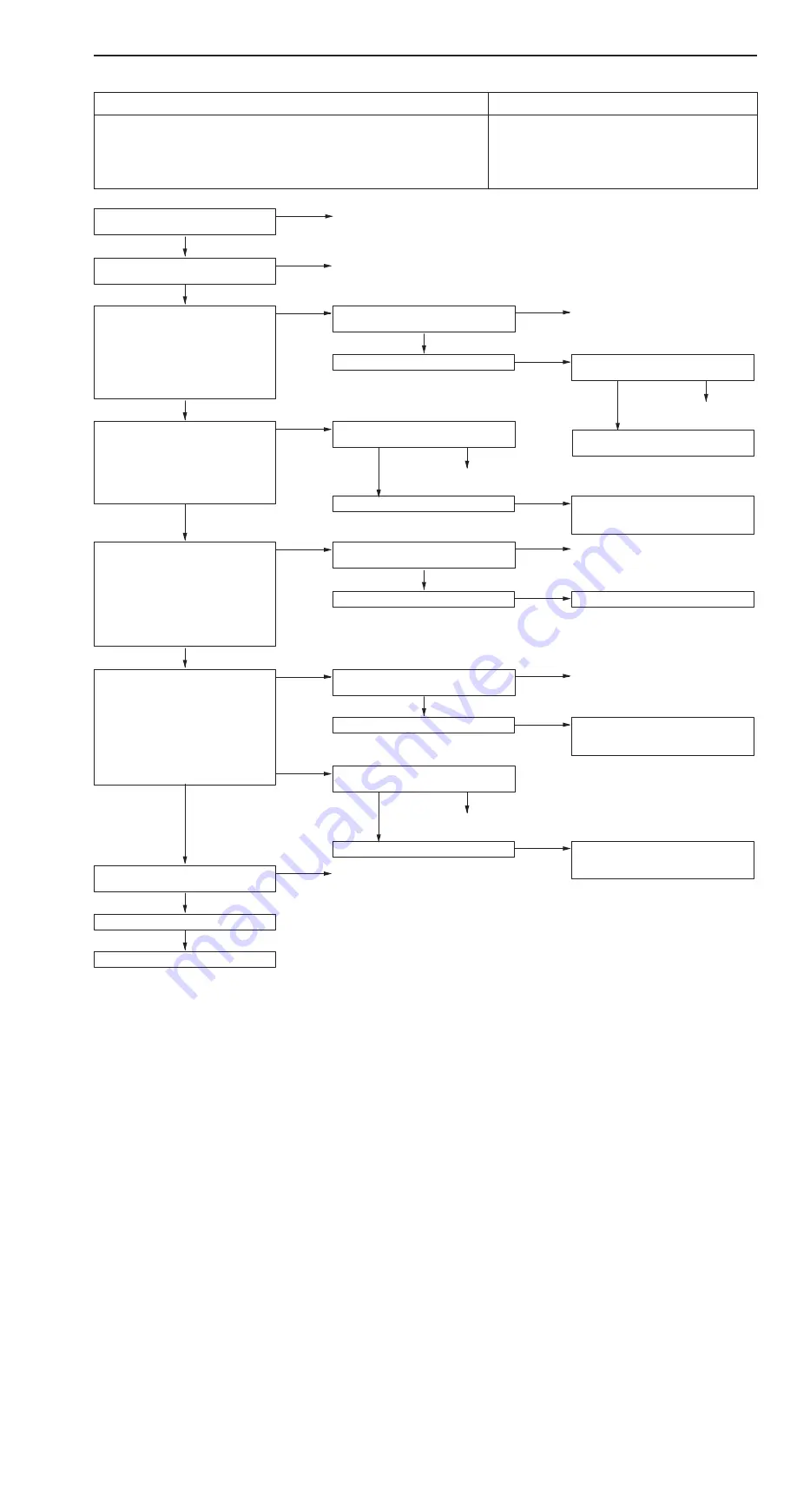

INSPECTION PROCEDURE 28

Fuel pump (low pressure) system

Probable cause

The engine-ECU turns on the fuel pump relay while the engine is cranking or running,

and supplies power source to the fuel pump (low pressure).

D

Malfunction of the fuel pump relay

D

Malfunction of the fuel pump (low pressure)

D

Open circuit or short-circuited harness wire in the

fuel pump (low pressure) circuit, or poor connector

contact

D

Malfunction of the engine-ECU

Check trouble symptom.

NG

Check the harness wire between the

fuel pump (low pressure) and earth,

and repair if necessary.

NG

Repair

OK

Check trouble symptom.

NG

Check the harness wire between the

fuel pump relay and engine-ECU, and

repair if necessary.

NG

Repair

OK

NG

Repair

OK

Check the ignition switch. (Refer to

GROUP 54 ± Ignition Switch.)

(2) NG

Check the following connector:

D-12

MUT-

II

Actuator test

07 Fuel pump (Refer to P.13A-76.)

OK

Normal

NG

Check the fuel pump relay. (Refer to

P.13A-102.)

NG

Replace

OK

Measure at fuel pump relay connector

A-41X.

D

Disconnect the connector, and

measure at the harness side.

D

Voltage between terminals 3, 4 and

earth

(Ignition switch: ON)

OK:

System voltage

NG

Check the following connectors:

C-72, C-74

NG

Repair

OK

Check trouble symptom.

NG

Check the harness wire between the

fuel pump relay and ignition switch.

OK

Measure at engine-ECU connector

C-17.

D

Disconnect the connector, and

measure at the harness side.

D

Voltage between terminal 21 and

earth (Ignition switch: ON)

OK:

System voltage

NG

Check the following connector:

A-41X

OK

Measure at engine-ECU connector

C-17.

D

Disconnect the connector, and

measure at the harness side.

D

Short circuit between terminal 21

and earth (Ignition switch: ON)

OK:

The fuel pump operates (its

operation sound can be

heard).

OK

Check the following connector:

C-17

NG

Repair

OK

Check trouble symptom.

NG

Replace the engine-ECU.

NG

Measure at fuel pump (low pressure)

connector D-17.

D

Disconnect the connector, and

measure at the harness side.

(1) Voltage between terminal 5 and

earth

(Ignition switch: ON)

OK:

System voltage

(2) Continuity between 4 and earth

OK:

Continuity

(1) NG

Check the following connectors:

C-24<LHD>, C-26<RHD>, D-12

NG

Repair

OK

Check trouble symptom.

NG

Check the harness wire between the

fuel pump relay and fuel pump (low

pressure), and repair if necessary.

OK

Check the following connector:

D-17

NG

Repair

OK

Check trouble symptom.

NG

Replace the fuel pump (low pressure).

Summary of Contents for Pajero Pinin 1999

Page 32: ...NOTES ...

Page 73: ...13A 1 FUEL CONTENTS GASOLINE DIRECT INJECTION GDI 13A FUEL SUPPLY 13B ...

Page 190: ...NOTES ...

Page 191: ...13B 1 FUEL SUPPLY CONTENTS FUEL TANK 2 Fuel Pump Module 4 ...

Page 214: ...NOTES ...

Page 222: ...NOTES ...

Page 256: ...NOTES ...

Page 274: ...NOTES ...

Page 282: ...NOTES ...

Page 360: ...NOTES ...

Page 412: ...NOTES ...

Page 443: ...32 1 POWER PLANT MOUNT CONTENTS ENGINE MOUNTING 2 TRANSMISSION MOUNTING 3 ...

Page 446: ...NOTES ...

Page 447: ......

Page 448: ......

Page 449: ......

Page 450: ......

Page 451: ......

Page 452: ......

Page 453: ......

Page 454: ......

Page 455: ......

Page 456: ......

Page 457: ......

Page 458: ......

Page 459: ......

Page 460: ......

Page 461: ......

Page 467: ...NOTES ...

Page 468: ...BASIC BRAKE SYSTEM 35A ANTI SKID BRAKING SYSTEM ABS 4WD 35B 35A 1 SERVICE BRAKES CONTENTS ...

Page 499: ...NOTES ...

Page 531: ...NOTES ...

Page 541: ...NOTES ...

Page 649: ...NOTES ...

Page 728: ...54A 1 CHASSIS ELECTRICAL CONTENTS CHASSIS ELECTRICAL 54A SMART WIRING SYSTEM SWS 54B ...

Page 883: ...NOTES ...

Page 919: ...NOTES ...