2Unpacking to Installation

Confirming the operation

2-27

・

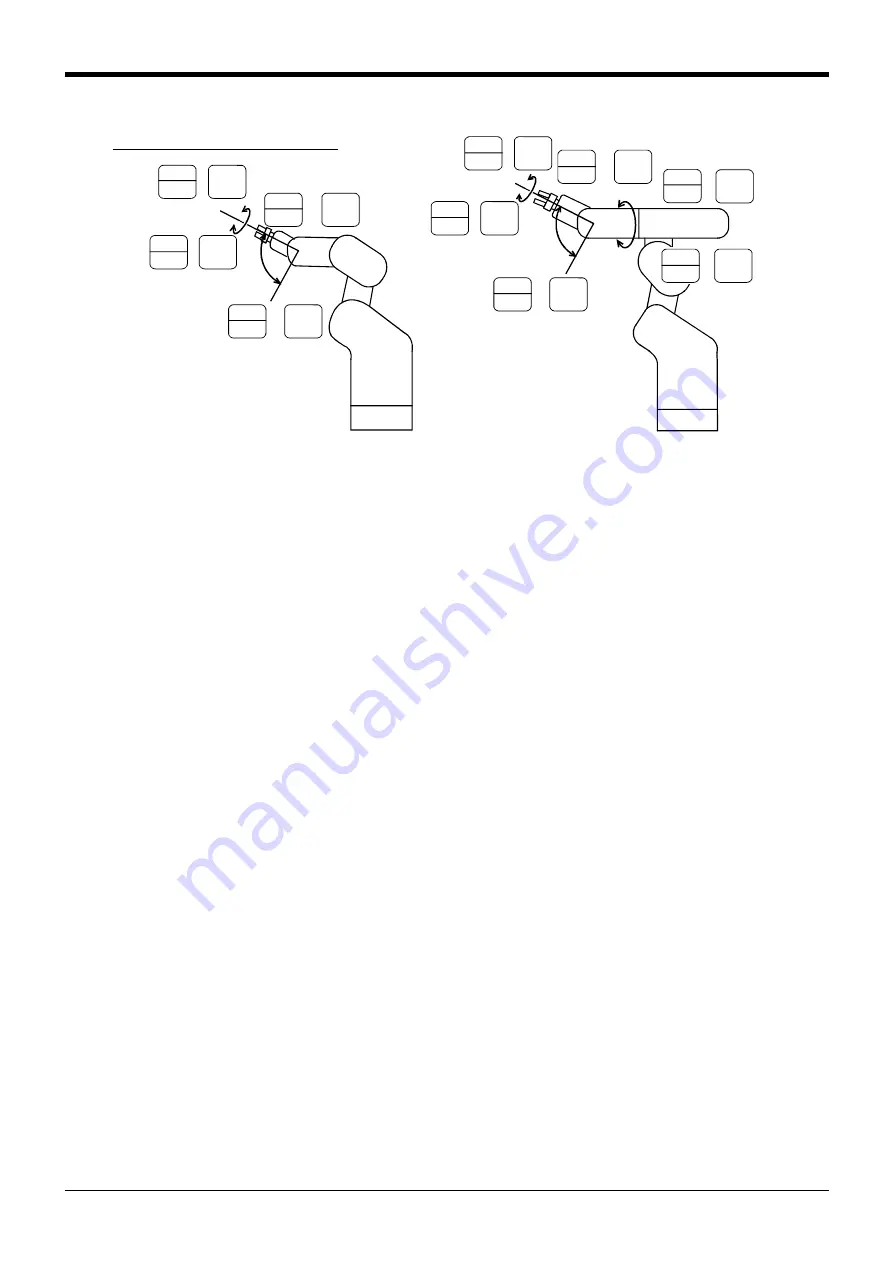

When the [MOVE] + [+A (J4)] keys are pressed, the J4-axis will rotate in the plus direction.

When the [MOVE] + [-A (J4)] keys are pressed, Rotate in the minus direction. (6-axis type only)

・

When the [MOVE] + [+B (J5)] keys are pressed, the J5-axis will rotate in the plus direction.

When the [MOVE] + [-B (J5)] keys are pressed, Rotate in the minus direction.

・

When the [MOVE] + [+C (J6)] keys are pressed, the J6-axis will rotate in the plus direction.

When the [MOVE] + [-C (J6)] keys are pressed, Rotate in the minus direction.

1

DEF

- B

(J5)

STEP

MOVE

+

5

STU

+ C

(J6)

STEP

MOVE

+

5

STU

+ C

(J6)

STEP

MOVE

+

+

-

J5 axis

-

+

J6 axis

+

-

J4 axis

5-axis type

+

-

-

+

J5 axis

J6 axis

1

DEF

- B

(J5)

+

STEP

MOVE

+

0

ABC

- C

(J6)

STEP

MOVE

STEP

MOVE

+

0

ABC

- C

(J6)

STEP

MOVE

+

6

VWX

B

(J5)

7

A

(J4)

STEP

MOVE

+

YZ_

+

6

VWX

B

(J5)

+

+

STEP

MOVE

2

A

(J4)

STEP

MOVE

+

GHI

-

6-axis type

* The flange position changes.

Interpolate the joint, taking care not to change the

control point. operation.

Changing the flange surface posture