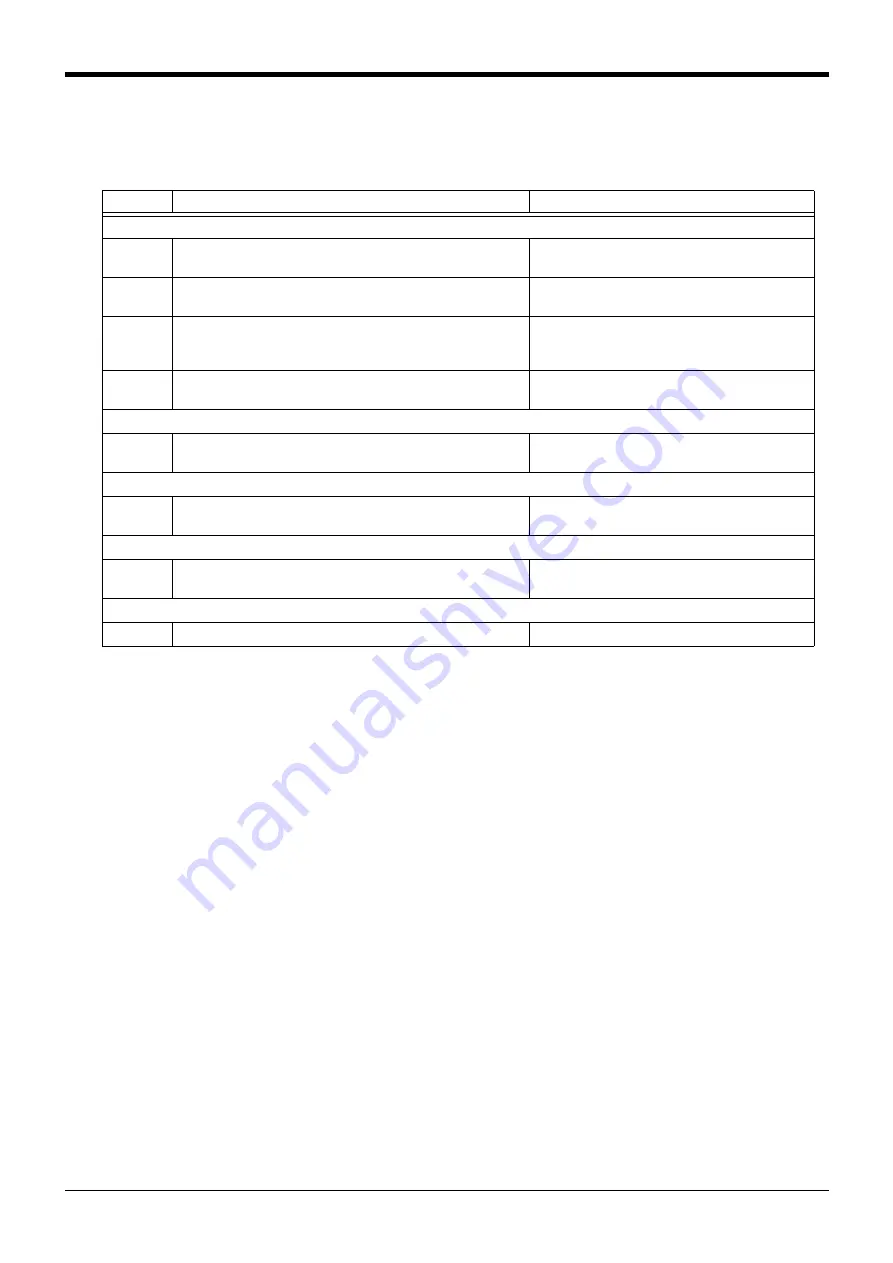

5Maintenance and Inspection

Inspection items

5-45

5.2.2 Periodic inspection

Carry out periodic inspection with the procedures given in

Table 5-2

:

Periodic inspection items (details)

Procedure

Inspection item (details)

Remedies

Monthly inspection items

1

Are any of the bolts or screws on the robot arm loose?

Securely tighten the bolts.

2

Are any of the connector fixing screws or terminal block terminal

screws loose?

Securely tighten the screws.

3

Remove the cover at each section, and check the cables for wear

damage and adherence of foreign matter.

Check and eliminate the cause.

If the cables are severely damaged, contact the

Mitsubishi Service Department.

4

It runs out of grease on the spring shaft for J2 axis.

Refer to

"5.3.6How to lubricate the spring shaft area"

3-month inspection items

1

Is the timing belt tension abnormal?

Is the inside of the arm dirty?

If the timing belt is loose or too tense, adjust it.

Wipe the dust with dry cloth or with alcohol.

6-month inspection items

1

Is the friction at the timing belt teeth severe?

If the teeth are missing or severe friction is found,

replace the timing belt.

Yearly inspection items

1

Replace the backup battery in the robot arm.

Exchange it referring to

2-year inspection items

1

Lubricate the grease at the harmonic reduction gears for each axis.