5 Maintenance and Inspection

Resetting the origin 5-90

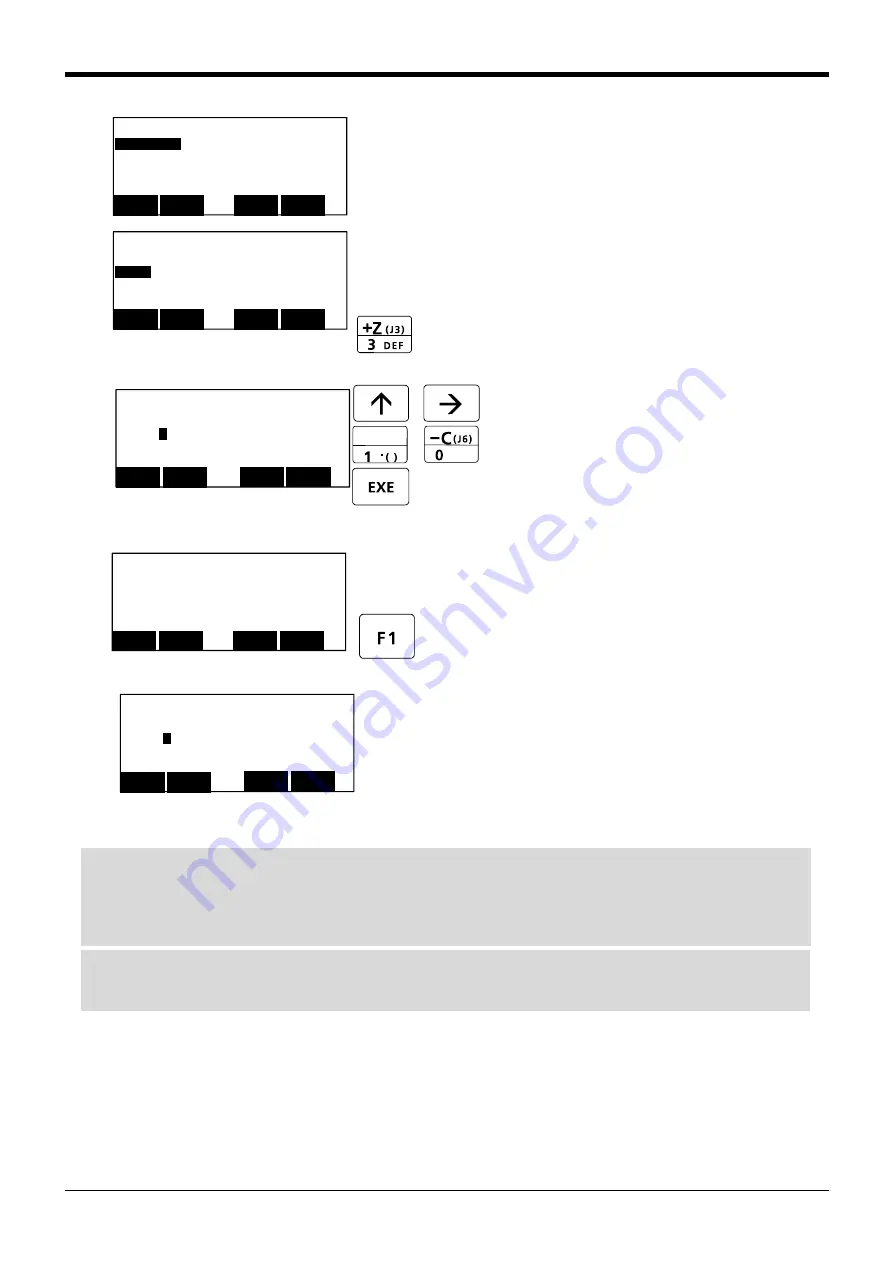

9) Press the [1] key, and display the Origin setting

selection screen.

10) Press the [3] key, and display the Tool selec

-

tion screen.

11) Input "1" into the J4 axis. Set "0" to other

axes.

12) Press the [EXE] key, and display Confirmation

screen.

13) Press the [F1] key, and the origin position is

set up.

14) Setting of the origin is completed.

15) Refer to

Page 98, "5.6.5 Recording the origin

in this manual, and record the origin data

on the origin data seal.

<ORIGIN/BRAKE>

1.ORIGIN

2.BRAKE

CLOSE

123

<ORIGIN>

1.DATA 2.MECH

3.TOOL

4.ABS

5.USER

CLOSE

123

~

SPACE

<TOOL>

J1:(

1

)J2:( 0 )J3:( 0 )

J4:( 0 )J5:( 0 )J6:( 0 )

J7:( 0 )J8:( 0 )

CLOSE

123

REL.

1

0

<ORIGIN> TOOL

CHANGE TO ORIGIN. OK?

No

123

Yes

<TOOL>

J1:(

1

)J2:( 0 )J3:( 0 )

J4:( 0 )J5:( 0 )J6:( 0 )

J7:( 0 )J8:( 0 )

CLOSE

123

REL.

COMPLETED

1

0

◇◆◇ Release the brake ◇◆◇

Do cursor movement into the parenthesis of each axis by the arrow key. The brakes can be released only for

the axis for which a "1" is displayed on the screen. If the brakes are not to be released, press the [0] key and

display a "0". If the [F1] key on the teaching pendant or the enabling switch is detached while the brakes are

released, the brakes will be work immediately.

◇◆◇ Select the axis of origin setting ◇◆◇

Do cursor movement into the parenthesis of each axis by the arrow key. The origin is set only for the axis for

which a "1" is displayed on the screen. If the origin is not to be set, press the [0] key and display a "0".

Summary of Contents for RV-2F Series

Page 2: ......