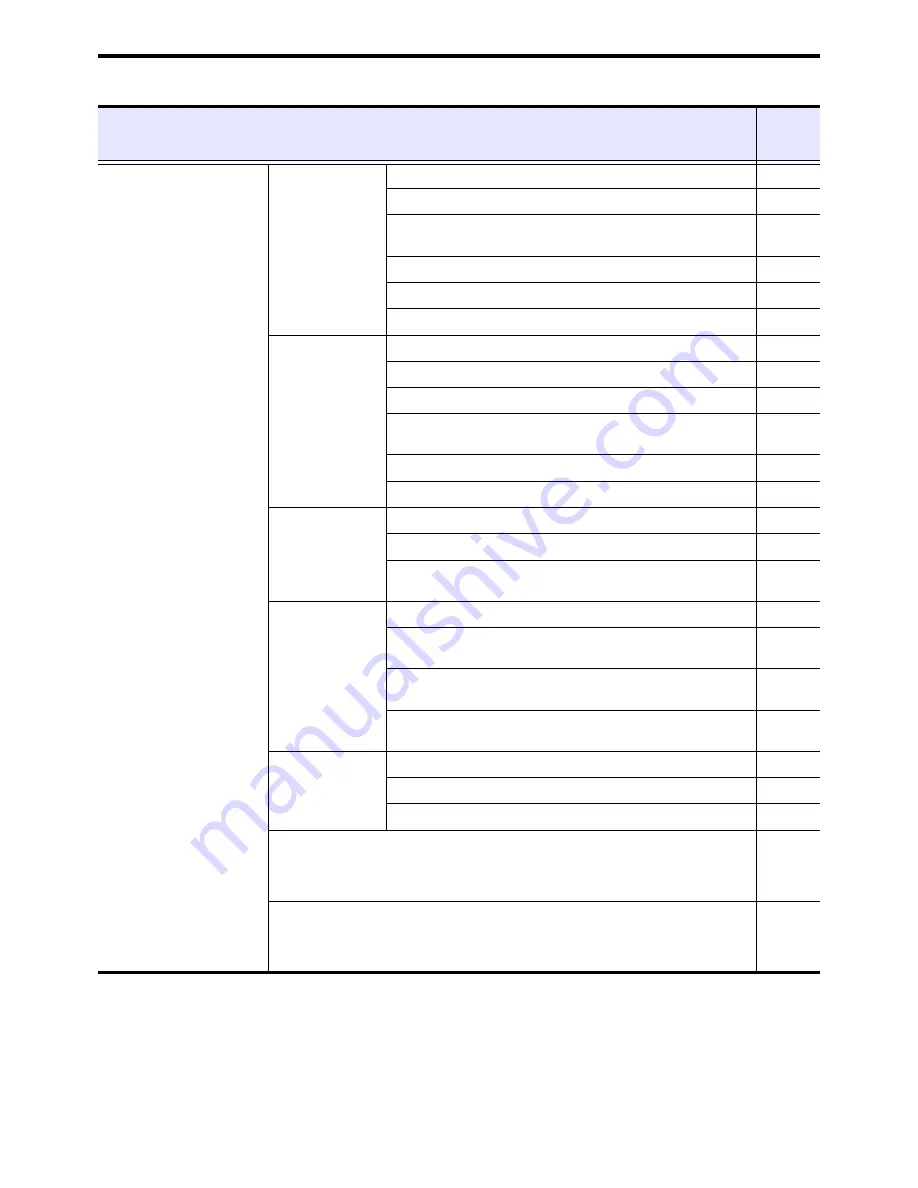

7-5

Chapter 7 MAINTENANCE SCHEDULE

Every one year

Basic engine

Belt and Belt Tension - Inspect and Adjust

8-2

Bolts and Nuts on the Engine - Check and Retighten

*2

Valve Clearance - Inspect and Adjust

(Check valve mechanism at the same time.))

*2

Inspecting the Vibration-isolating Rubber *1

*2

Foundation Bolts - Inspect *1

*2

Couplings - Inspect or Replace

*2

Fuel system

Fuel Tank - Drain Water

*1

8-5

Water Separator - Drain Water*1

*2

Fuel Filters (Wire-element Type) - Drain Water

8-7

Fuel Injection Nozzle Spray Condition and Spray Pres-

sure - Inspect and Adjust

*2

Fuel Injection Timing - Inspect and Adjust

*2

Fuel Pipe - Inspect

8-10

Engine

lubricating

system

Oil Pipe - Inspect

8-14

Engine Oil Properties - Analyze

*2

Engine Oil Pressure (Maintenance operation) - Inspect

and adjust

*2

Cooling system

Water Pump - Inspect

*2

Solenoid Valve and Pressure Reducing Valve of the Cool-

ing system - Inspect, disassemble and clean *1

*2

Strainer (Including with/ball tap) of Cooling Water -

Inspect, Disisassemble and clean *1

*2

Coolant Properties (when only soft water is used) -

Inspect (change coolant according to the analysis results)

*2

Electrical system

Starter - Inspect

8-20

Alternator - Inspect

8-20

Specific Gravity of Battery Electrolyte - Check

*1

8-19

Auxiliary Devices Operation - Check *1

High coolant temperature, low oil pressure, overspeeding, starting failure,

water supply failure, undervoltage, overvoltage, overcurrent, low coolant

level in tank, low fuel level in tank, etc.

*2

Auxiliary Devices Operation - Eheck

Engine control, fuel transfer pump, governor motor, room ventilating fan,

solenoid, storage pump, water tank ball tap, water heater, oil heater, oil prim-

ing pump, etc.

*2

Table 7-2 Periodic Maintenance Chart for Emergency Engine

Interval and service item

Refer-

ence

page