8-21

Chapter 8 FUEL SYSTEM

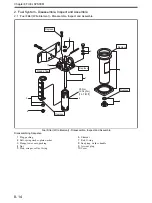

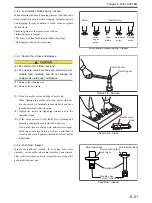

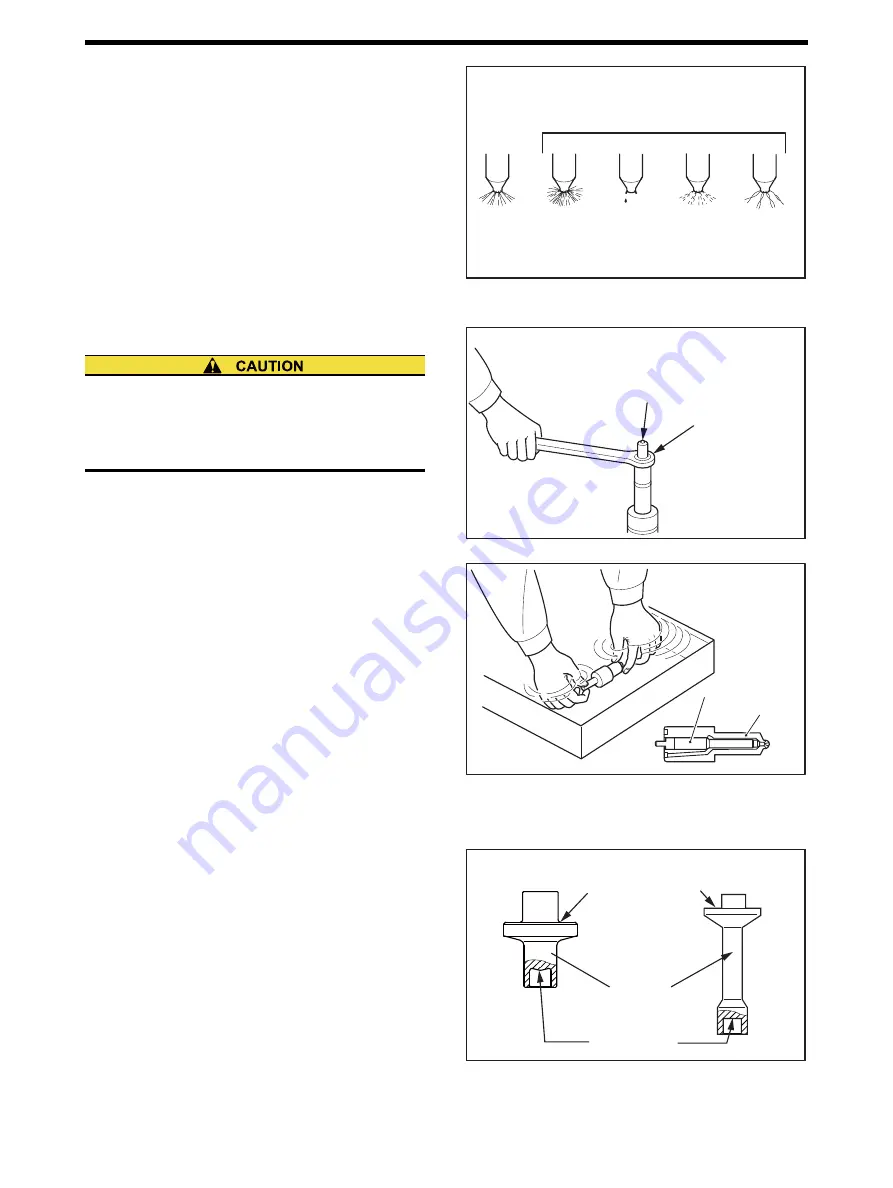

2.4.2 Fuel Injection Nozzle Spray - Inspect

When adjusting the nozzle opening pressure with the nozzle

tester, inspect for nozzle orifice clogging, fuel spray pattern

and dripping. If spray condition is faulty, clean or replace

the nozzle tip.

Checking points of fuel spray are as follows:

Injection spray is straight.

The spray is of fine fuel droplets without big drops.

No dripping is shown after injection.

Fuel Injection Nozzle Spray - Inspect

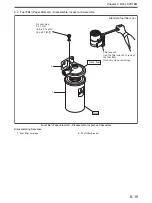

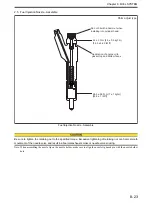

2.4.3 Nozzle Tip - Clean and Replace

(1)

Remove the retaining nut.

(2)

Remove the nozzle tip.

Nozzle Tip - Remove

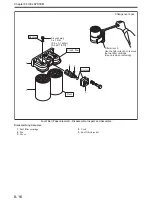

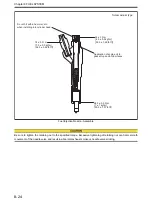

(3)

Clean the needle valve and body of nozzle tip.

When cleaning the needle valve and nozzle tip body,

use clean wash oil. Assemble the needle valve and body

in clean diesel fuel after cleaning.

(4)

Tighten the nozzle tip tightening retainer nut to the

specified torque.

(5)

If the spray pattern is still faulty after cleaning and

adjusting, change the nozzle tip with a new one.

New nozzle tips are coated with anti-corrosive agent.

Wash the nozzle tips before use. First wash them in

wash oil, and wash it again with clean diesel fuel before

installation.

Nozzle Tip - Clean

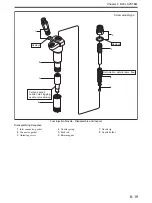

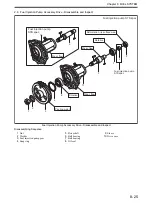

2.4.4 Push Rod - Inspect

Inspect the push rod visually. If its spring seat wears

unevenly, or its needle valve contact surface wears remark-

ably, or the cavitation occurs on its tapered area, replace the

push rod with a new one.

Push Rod - Inspect

Good

Large

angel

spray

After

dribble

Intermittent

spray

Whirling

spray

Faulty spray

(a) Be careful not to hit the nozzle tip.

(b) The needle valve and body are precision parts.

Handle them carefully, and do not change the

original valve and body combination.

Retaining nut

Nozzle tip end

Needle valve

Body

Spring seating face

local wear

Shim adjust type

Screw adjust type

Needle valve

contact surface wear

Cavitation

Summary of Contents for S12A2

Page 1: ...SERVICE MANUAL September 2010 Pub No 99269 20170 199269 20170 ...

Page 2: ......

Page 16: ......

Page 20: ......

Page 42: ......

Page 44: ......

Page 68: ......

Page 69: ...3 1 Chapter 3 SERVICE TOOLS 1 Special Tools 3 3 ...

Page 70: ......

Page 78: ......

Page 82: ......

Page 136: ......

Page 174: ......

Page 218: ......

Page 220: ......

Page 242: ......

Page 244: ......

Page 294: ......

Page 310: ......

Page 320: ......

Page 322: ......

Page 334: ......

Page 354: ......