2-21

Chapter 2 SERVICE DATA

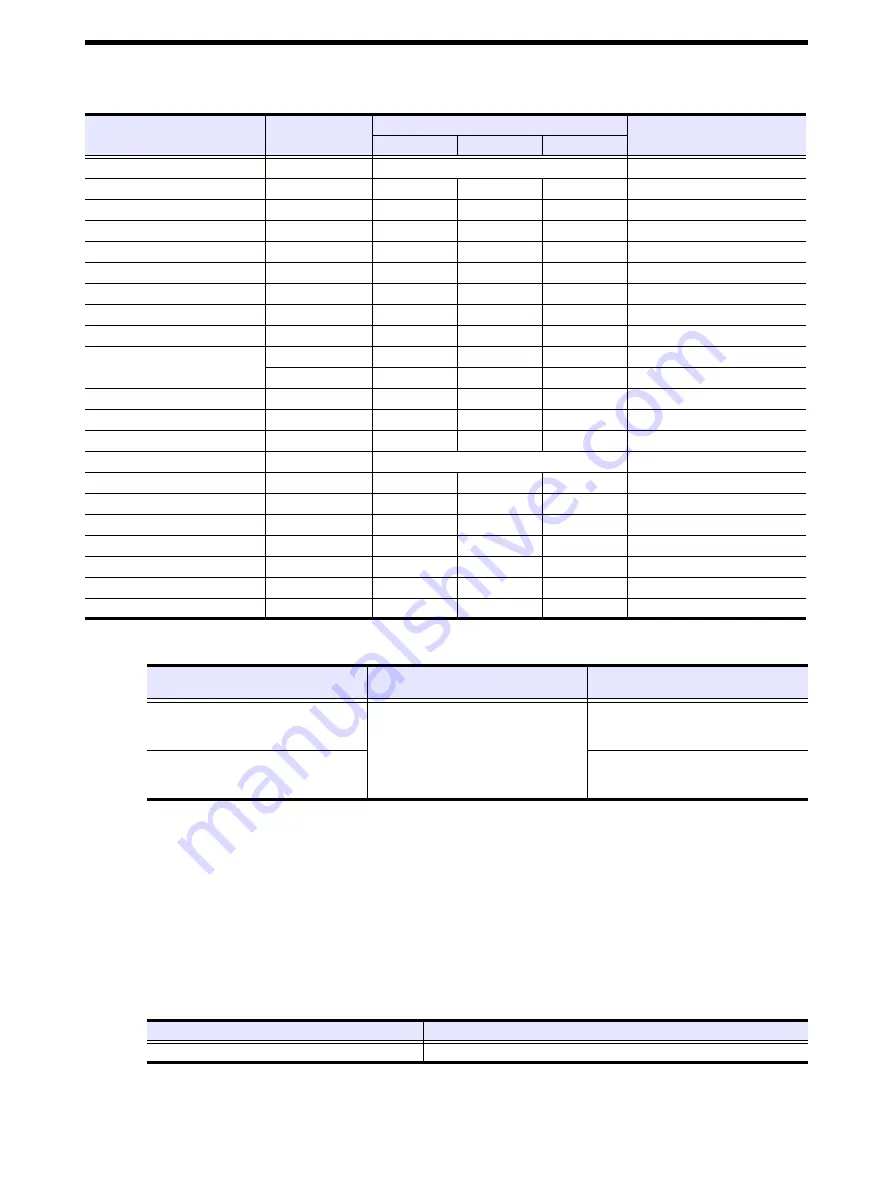

2. Tightening Torque Table

2.1 Tightening Torque Spec for Basic Engine

Note:(a) Tighten cylinder head bolts as shown in the table below.

For tightening procedure, refer to "Cylinder Head Bolt - Tighten" of "ASSEMBLY OF BASIC ENGINE".

(b) For tightening of main bearing cap bolts and main bearing cap side bolts, follow the specified sequence. Snug tighten

the all bolts to the half of specified torque, and after the snug tightening of all the bolts is completed, then finally tighten

them to the specified torque.

For tightening procedure, refer to "Main bearing cap - Install" of "ASSEMBLY OF BASIC ENGINE."

(c) Tighten piston cooling nozzle check valves to the specified torque.Do not over-tighten. If the tightening torque exceeds

the specified torque, it could cause the check valve to malfunction, which may result in piston seizure.

(d) When [Wet] is indicated, apply engine oil to the threads and bolt seat surface.

(e) Connecting rod cap bolts should be tightened as shown below.

(f) Parts (bolts/nuts) indicated by 2-time tightening method are to be tightened as follows: tighten to the specified torque,

and loosen, then retighten to the specified torque.

Description

Dia x Pitch

(M-thread)

Tightening torque

Remarks

N·m

kgf·m

lbf·ft

Cylinder head bolt

20 × 2.5

Note (a)

[Wet]

Rocker cover

12 x 1.25

15 ± 2

1.5 ± 0.2

10.9 ± 1.5

Rocker shaft bracket

12 x 1.75

49 ± 2.5

5 ± 0.25

36 ± 1.81

Rocker arm (lock nut)

12 x 1.25

64 ± 6.4

6.5 ± 0.65

47 ± 4.70

Bridge (lock nut)

10 x 1.25

55 ± 5.5

5.6 ± 0.56

40.5 ± 4.05

Camshaft gear

30 x 1.5

294 ± 15

30 ± 1.5

217 ± 10.9

Left-hand thread

Main bearing cap

24 × 3.0

588 ± 29

60 ± 3.0

434 ± 22

[Wet], Note (b)

Main bearing cap (side bolt)

16 × 2.0

147 ± 7.4

15 ± 0.75

109 ± 5.42

[Wet], Note (b)

Piston cooling nozzle

12 x 1.75

34 ± 1.7

3.5 ± 0.17

25.3 ± 1.23

Note (c)

Timing gear case

12 x 1.75

98 ± 4.9

10 ± 0.5

72 ± 3.6

16 x 1.5

255 ± 12.8

26 ± 1.3

188 ± 9.4

Rear plate

12 x 1.25

98 ± 4.9

10 ± 0.5

72 ± 3.6

Front mounting bracket

20 x 1.5

392 ± 20

40 ± 2.0

289 ± 14

Rear mounting bracket

18 × 2.5

245 ± 12

25 ± 1.3

180 ± 9.4

Connecting rod cap

18 x 1.5

Note (e)

[Wet]

Balance weight

16 x 1.5

196 ± 10

20 ± 1.0

145 ± 7.2

Flywheel

22 x 1.5

539 ± 27

55 ± 2.8

397 ± 20.3

[Wet]

Damper

22 x 1.5

539 ± 27

55 ± 2.8

397 ± 20.3

Idler shaft

12 x 1.75

54 ± 2.7

5.5 ± 0.28

39.8 ± 2.03

Idler gear thrust plate

10 x 1.25

39 ± 3.9

4.0 ± 0.4

28 ± 2.9

Fuel injection pump gear

30 x 1.5

294 ± 15

30 ± 1.5

217 ± 10.9

Oil pump gear

27 × 1.5

294 ± 15

30 ± 1.5

217 ± 10.9

Parts name

Torque method (2-time tightening

method)

Angle method (2-time tightening

method)

Cylinder head bolt (short)

392 ± 20 N·m

{40 ± 2.0 kgf·m}

[289.1± 14.75 lbf·ft]

118 ± 5.9 N·m {12 ± 0.6 kgf·m}

[87± 4.3 lbf·ft]

→

Type 1:75 ± 3° Type 2:110± 3°

Cylinder head bolt (long)

196 ± 9.8 N·m {20 ±1.0 kgf·m}

[144 ±7.2 lbf·ft]

→

Type 1: 75 ± 3° Type 2:110± 3°

Torque method (2-time tightening method)

Angle method (2-time tightening method)

343 ± 17 N·m {35 ± 1.8 kgf·m} [253 ± 12 lbf·ft]

Snug torque 147 ± 7.4 N•m {15 ± 0.75 kgf•m} [147 ± 7.4 lbf•ft]

→

45 ± 3°

Summary of Contents for S12A2

Page 1: ...SERVICE MANUAL September 2010 Pub No 99269 20170 199269 20170 ...

Page 2: ......

Page 16: ......

Page 20: ......

Page 42: ......

Page 44: ......

Page 68: ......

Page 69: ...3 1 Chapter 3 SERVICE TOOLS 1 Special Tools 3 3 ...

Page 70: ......

Page 78: ......

Page 82: ......

Page 136: ......

Page 174: ......

Page 218: ......

Page 220: ......

Page 242: ......

Page 244: ......

Page 294: ......

Page 310: ......

Page 320: ......

Page 322: ......

Page 334: ......

Page 354: ......