37

OPERATING PROCEDURE

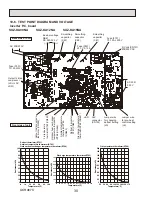

PHOTOS

5. Removing outdoor fan motor

(1) Remove the cabinet and panels. (Refer to procedure 1.)

(2) Disconnect the following connectors:

<Inverter P.C. board>

CN931, CN932 (Fan motor)

(3) Remove the propeller nut. (See Photo 7)

(4) Remove the propeller. (See Photo 7)

(5) Remove the screws fixing the fan motor. (See Photo 7)

(6) Remove the fan motor.

6. Removing the compressor and 4-way valve

(1) Remove the cabinet and panels. (Refer to procedure 1.)

(2) Remove the inverter assembly. (Refer to procedure 2.)

(3) Recover gas from the refrigerant circuit.

NOTE:

Recover gas from the pipes until the pressure

gauge shows 0 PSIG.

(4) Detach the welded part of the suction and the discharge

pipe connected with compressor.

(5) Remove the nuts of compressor legs.

(6) Remove the compressor.

(7) Detach the welded part of pipes connected with 4-way

valve. (See Photo 8.)

Photo 6

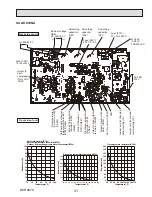

Photo 8

Propeller nut

Photo 7

Screws of the outdoor fan motor

Propeller

Defrost thermistor

Outdoor heat exchanger

temperature thermistor

Welded parts of 4-way valve

OCH467C

Summary of Contents for SUZ-KA09NA

Page 41: ...41 OCH467C ...