Chapter 4 Daily Maintenance

TDP-324

-55-

4.

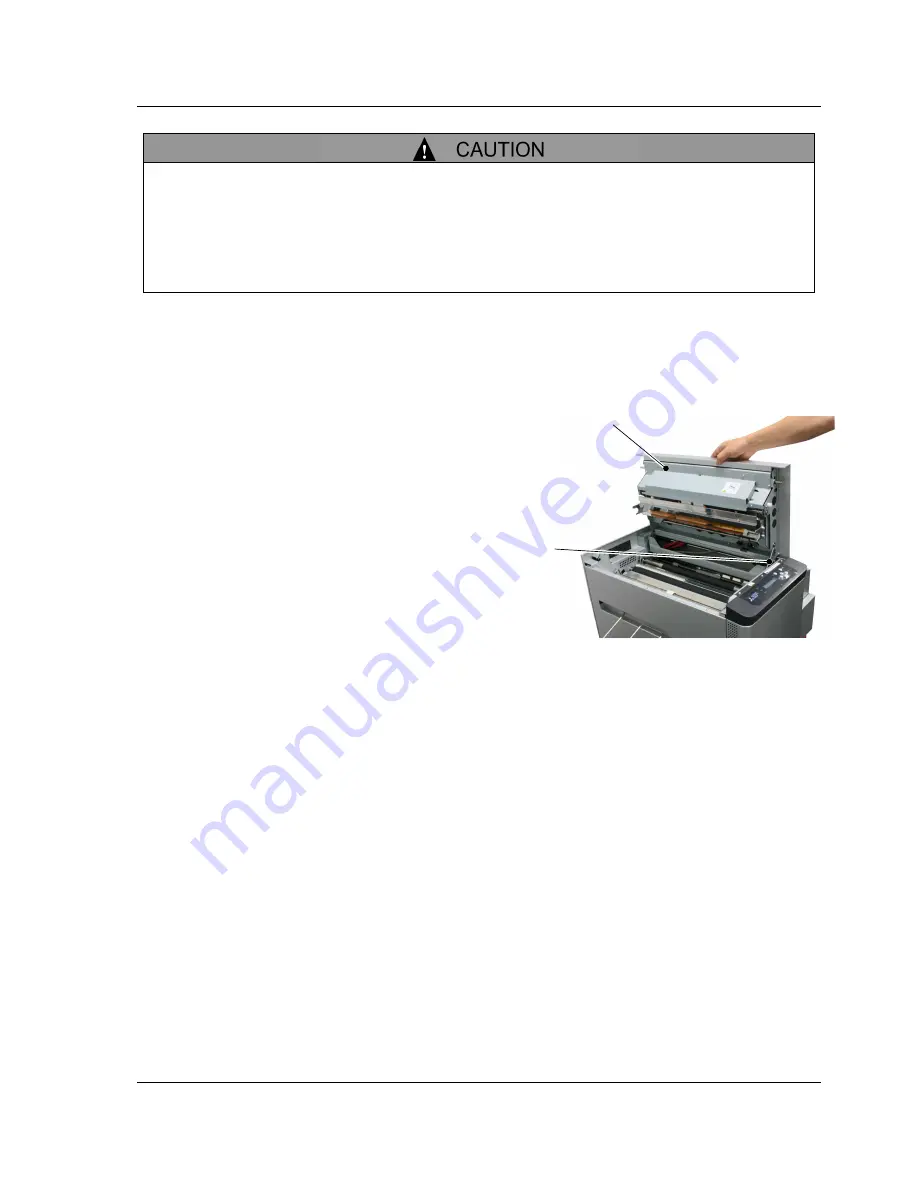

Release the locking lever and close the

upper cover slowly.

5.

Reset the plate.

Upper cover

Locking lever

Be careful not to scratch the rubber surface.

Dirt on the platen roller can affect the print size accuracy.

After cleaning, wait until recommended cleaning fluid has evaporated sufficiently before

starting printing. (It is recommended that the Thermal Digiplater be left for about 5 minutes

after cleaning

.)

Do not put your hand or cleaning cloth close to the inside of the Thermal Digiplater during

the platen roller rotation.

Summary of Contents for TDP-324

Page 1: ......

Page 2: ......

Page 4: ......

Page 54: ...Chapter 3 Use of Operation Panel TDP 324 48 MEMO...

Page 72: ...Chapter 4 Daily Maintenance TDP 324 66 MEMO...

Page 82: ...Chapter 7 After sales service TDP 324 76 MEMO...

Page 84: ...Chapter 7 After sales service TDP 324 78 MEMO...