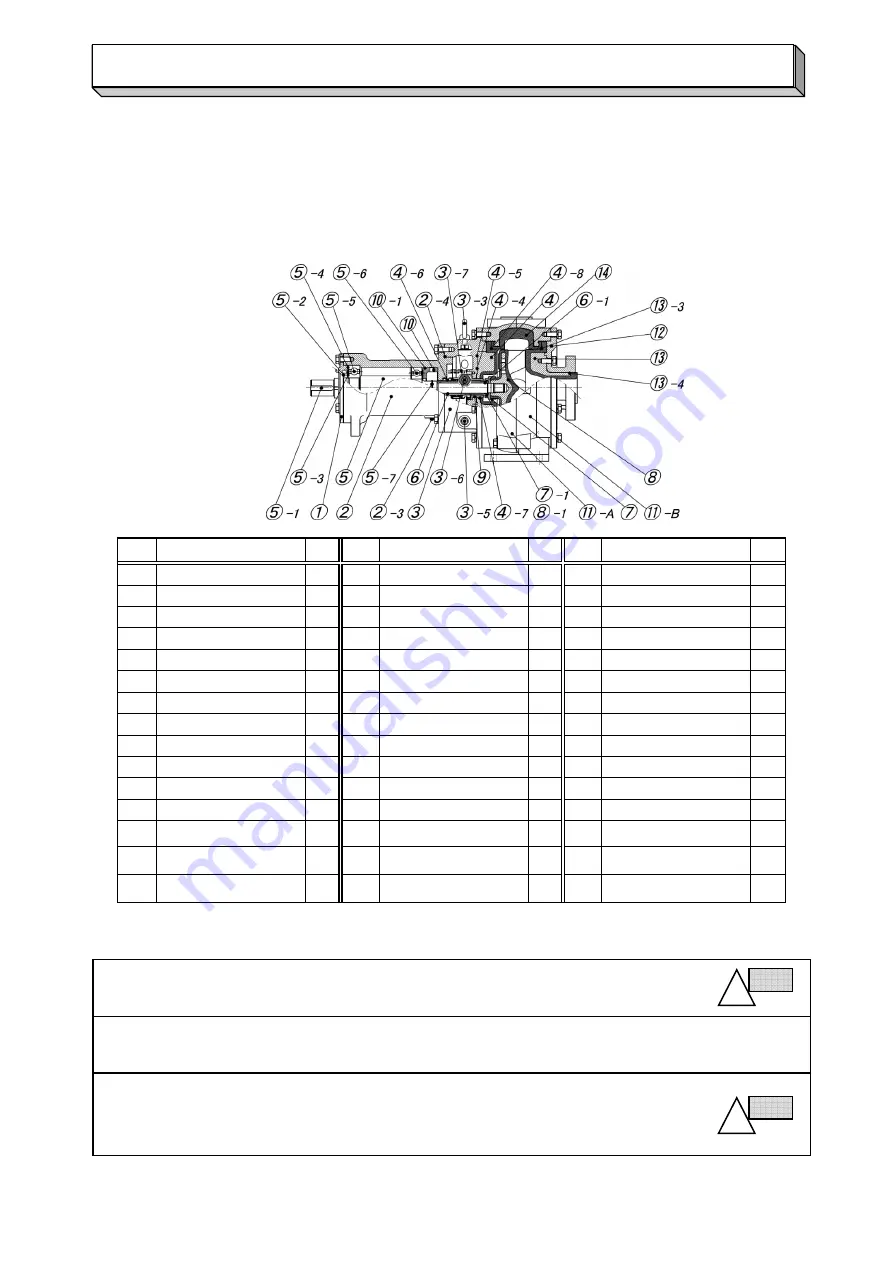

The procedures for assembling the pump are as shown below. Disassembly is the reverse of assembly.

The procedures for assembling the standard type are described. For special specifications, contact

your dealer or the product manufacturer.

【Schematic diagram of the pump】

No,

No,

No,

1

5

10

2

5-1

10-1

2-3

5-2

11-A

2-4

5-3

11-B

3

5-4

12

3-3

5-5

13

3-5

5-6

13-3

3-6

5-7

13-4

3-7

6

14

4

6-1

4-4

7

4-5

7-1

4-6

8

4-7

8-1

4-8

9

【注意事項】

●

【When disassembling】

When disassembling the pump, close the discharge and suction valves and drain

off the liquid from the pump through the drain cover. Note that the liquid may

splatter. Special attention should be given to chemical liquid.

- 10 -

●

Before assembling or disassembling the pump, be sure to power off the electric

motor.

●

When placing an order or requesting a quote for parts, be sure to contact your

dealer and tell the model and manufacturer's serial number.

O ring (COM type)

1

R-ring (COR) / M-ring (COM)

1

O ring (COM type)

1

O ring (COM type)

1

Double mechanical seal

1

Impeller

1

O ring

1

O ring (COR type)

1

O ring

1

Boss cover (COR type)

1

Back plate

1

O ring

2

Oil

600cc

Shaft sleeve

1

Inner volute

1

Oil gauge

2

O ring

1

O ring (COM type)

1

Oil supply and drain plugs

4

Ball bearing

1

O ring (COM type)

1

Lifting eye

1

Ball bearing

1

Suction plate

1

Mechanical seal case

1

Bearings wave washer

1

Suction cover

1

O ring

1

Lock washer

1

Outer casing B

1

Plug

1

Bearing nut

1

Outer casing A

1

Bearing case

1

Key

1

O ring

1

Bearing case cover

1

Shaft

1

Bearing plate

1

Parts

Q'ty

Parts

Q'ty

Parts

Q'ty

1CO Assembling (disassembling) procedures

!

!

!

!

Danger

Danger

Danger

Danger

!

!

!

!

Danger

Danger

Danger

Danger