④

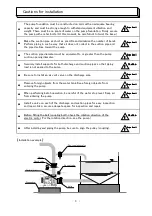

Attach the oil drain plug and sight glass to the seal case.

⑤

Insert the seal washer (with liquid gasket applied to both sides) and mechanical seal rotor (large)

into the casing cover and fasten them with the mechanical seal stationary plate.

⑥

Attach the O ring and asseble the casing

cover and seal case.

※At this moment, be careful that the sliding

surface of the mechanical seal does not come

in contact with the shaft and other parts.

⑦

Turn the shaft by hand to check whether there

is anything wrong with the shaft.

Conduct air tightness tests as necessary.

Air tightness test: Leave the mechanical seal for 10 minutes with a pressure of 0.3 MPa applied to

air at room temperature from the threaded hole of the oil feed plug.

⑧

Pour oil through the oil feed plug and attach the oil feed plug and eye bolt.

※Pour the specified amount of oil. Too much or too little oil may cause early failure.

⑨

Attach the seal washer (with liquid gasket applied to both sides)

and boss cover to the shaft.

⑩

The impeller is of screw type. Secure the shaft and screw

the impeller squarely into the shaft clockwise.

※ The impeller is a rubber lined product. Be careful not to

damage it. Do no hit it with a hammer.

⑪

Turn the shaft by hand to check whether the impeller comes in contact with the suction cover.

4、Assembling the pump (pump)

① Attach the rotating part to the assembly on the casing side.

②

Turn the shaft by hand to check whether the impeller

comes in contact with the suction cover.

※

Take out the nut

Take out the nut

Take out the nut

Take out the nut

to remove the rotating part from the

assembly on the casing side. Never take out the bolt.

- 17 -

An air tightness test shows whether the mechanical seal has been assembled properly.

Apply silicon grease to the thread and attach the impeller.

Bos

s

cover

Im

pell

er

Seal washer

O ring

Mechanical seal

Casing cover

Sight glass

Oil drain plug

Mechanical seal

Seal washer

Oil feed plug

Eye bolt

Assembly on the casing side

Rotating part

Spring washer

Nut