Document No.: E20-018-00

11

6.3.

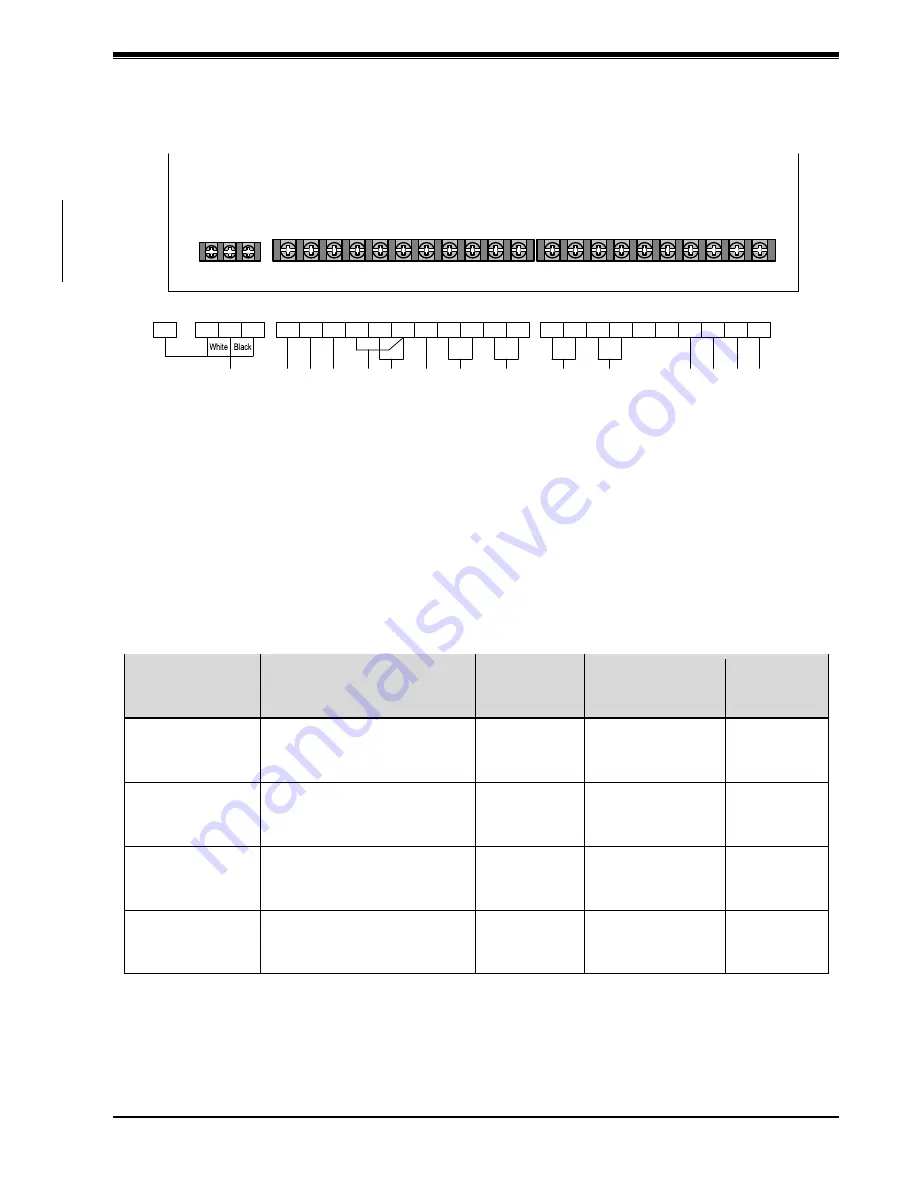

Terminal Arrangement on Control Circuit Board

Terminal arrangement on the I/O board is as shown below.

Figure 6-2: Terminal arrangement on EJ-210 I/O board

6.4.

Wires for Use

Use wire appropriate for the application that does not exceed the maximum length.

Table 6-1: List of wires

Location used

Standard

Cross-

sectional area

[mm

2

]

Maximum length

[m]

Remarks

Signal wire

High heat-resistant wire

Example: CV wire

(*)

, HIV

wire

(*)

+ heat-resistant tube

1.25 or larger

5

Procured on-

site

RS-422

communication

line wire

Twisted pair cable

FCPEV

(*)

, φ0.9 mm, 2P,

Copper braided screen

―

2

(Boiler to

equipment)

Procured on

site

M-NET3

communication

line wire

Shielded LAN cable

CAT 5 or above, single-wire

STP straight cable

―

100

(HUB to

equipment)

Procured on-

site

Steam pressure

sensor wire

AWM2840

(*)

(3-core shielded

cable)

―

2

Supplied as

optional

extra

NOTE 1: The RS-422 communication line wire is required for a boiler with BL-model or XJ1-model

controller mounted.

NOTE 2: The steam pressure sensor wire is required to install the optional steam pressure sensor.

EJ21 I/O board

66

5

45

85

22

13

6

79

19

36

76

P-

P1

P+

J4

J3

J2

J1

89

88

6

79 19 76 36

13 22 85 45

5

66

P+ P1 P-

J3 J2 J1 88 89

J4

FG

N(S)

G(FG)

G(FG)

N(S) G(FG)

L(R)

L(R)

G(FG)

Po

wer

su

p

p

ly

(L

p

h

as

e

)

Fra

m

e

g

ro

un

d

(F

G

)

Po

wer

su

p

p

ly

(N

p

ha

se

)

Si

g

n

a

l o

u

tp

u

t

(b

o

ile

r o

pe

ra

tio

n

)

Si

g

n

a

l o

u

tp

u

t

(e

m

e

rg

e

n

cy

s

to

p

)

Si

g

n

a

l o

u

tp

u

t

(h

ig

h

fi

re

in

stru

cti

o

n)

Si

g

n

a

l o

u

tp

u

t

(c

om

bu

sti

on

in

stru

cti

on)

Si

g

n

a

l i

np

u

t

(o

p

e

ra

tio

n

)

(L

p

h

as

e

)

Ste

a

m

p

re

ss

u

re

se

ns

o

r (o

p

tio

n

a

l)

Sig

na

l i

npu

t (o

pe

ra

tion

)

(N

p

h

a

se

)

Si

g

n

a

l

in

p

u

t

(b

oi

le

r

fa

il)

Si

g

n

a

l i

np

u

t

(s

ta

rt)

Si

g

n

a

l i

np

u

t

(h

ig

h f

ire

)

Si

g

n

a

l i

np

u

t

(c

om

b

us

tio

n

)

Box terminals

Gray

Red