CHAPTER 4: GETTING STARTED

MODEL 250DP DUAL PULSE

RESISTANCE WELDING POWER SUPPLY

990-280

4-5

CAUTION:

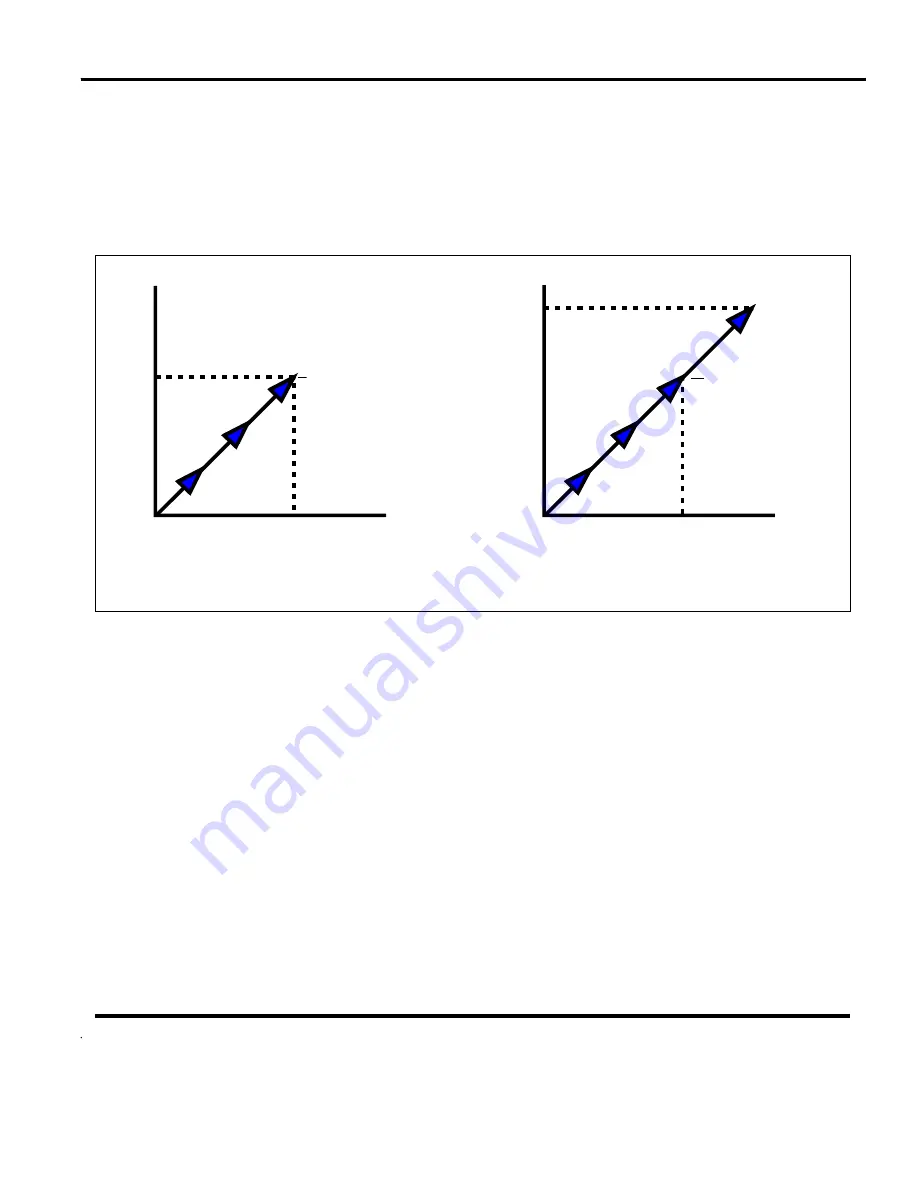

Resist the temptation to increase the downspeed by increasing the regulator setting since this

increases the force applied to the workpiece by the electrodes (see figure 4-4). Illustration (a) in figure 4-4

shows the correct air pressure adjustment – the

actual

force equals the firing force setting. Illustration (b)

shows the result of excessive air pressure – the

actual

force is much greater than the firing force setting.

Excessive air pressure causes the electrodes to mushroom as well as wear faster.

11 If a higher welding force is necessary, reset the force indicator on the weld head to a

larger

number,

then repeat Steps 9 and 10.

12 If a lower welding force is necessary, reset the force indicator on the weld head to a

smaller

number,

reduce

the pressure regulator, which controls the air pressure on the top of the air cylinder, then repeat

Steps 9 and 10.

13 If appropriate, configure the Weld Sentry. Press [MENU], select WELD SENTRY followed by

SYSTEM SETUP.

14 If appropriate, configure the Weld Sentry print options, relay outputs, and communications options. Set

the Weld Sentry clock for the correct time and date.

Welding Force

Actual

Force

Force Setting

Dial

Indicator

Welding Force

Firing Switch Closes

Force Setting

Dial

Indicator

Firing Switch Closes

Actual

Force

a)

b)

Figure 4-4. Results of Excessive Air Pressure