CHAPTER 5: OPERATING INSTRUCTIONS

MODEL 250DP DUAL PULSE

RESISTANCE WELDING POWER SUPPLY

990-280

5-3

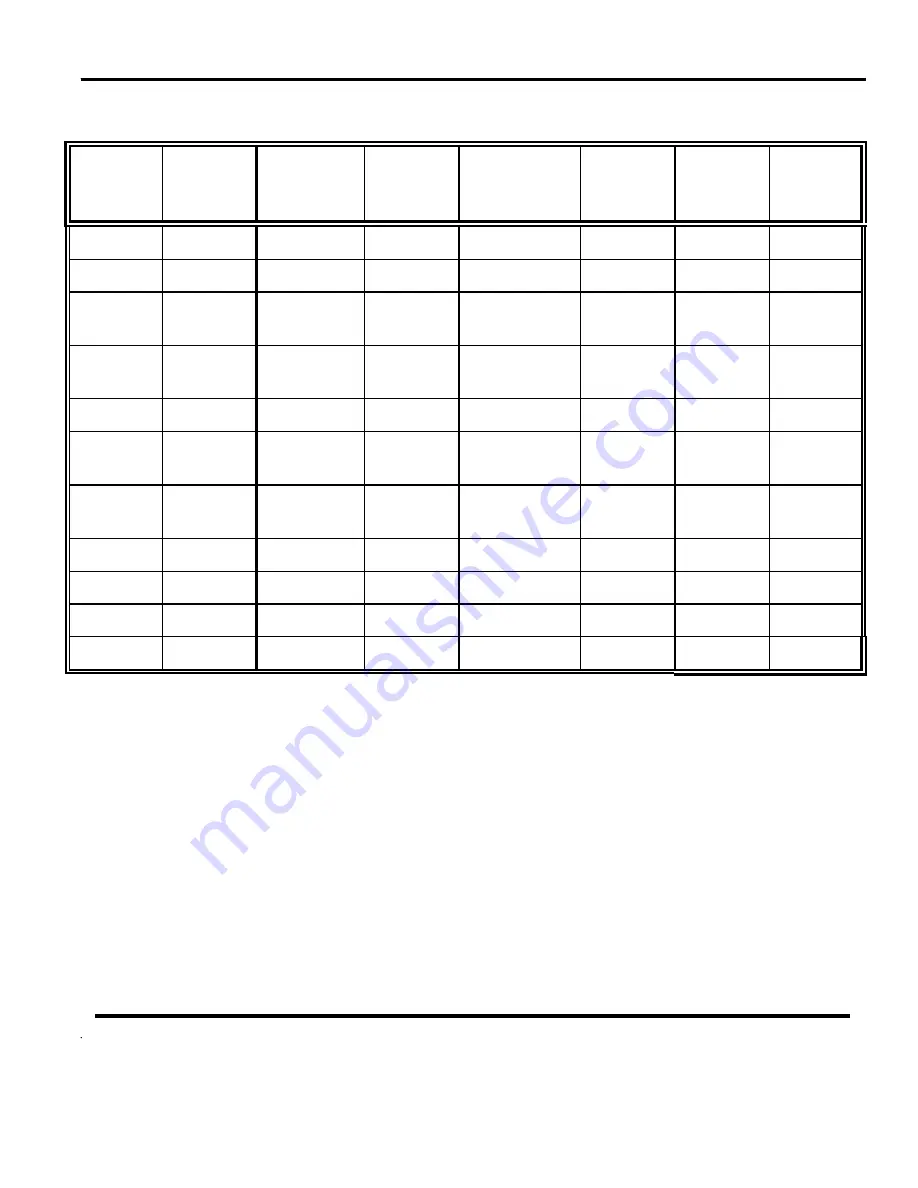

Table 5-1. Recommended Electrode Materials

Material

Electrode

RWMA

Type

Material

Electrode

RWMA

Type

Material

Electrode

RWMA

Type

Material

Electrode

RWMA

Type

Alumel

2 Evanohm

14 Kulgrid

2 Palladium 14

Aluminum 1 Gold

11 Magnesium

2 Rhenium

2

Aluminum

Alloys

1 Gold

Plated

Dumet

2 Manganin

2 Silver

11

Beryllium

Copper

2 Gold

Plated

Kovar

2 Molybdenum 2 Stainless

Steel

2

Brass

2, 11

Hastalloy X

2

Nichrome

2

Tantalum

2

Bronze

2 Inconel

2 Nickel

2 Tinned

Brass

14

Chromel

2 Invar

2 Nickel

Alloy 2 Tinned

Copper

14

Consil

11 Iridium

2 Niobium

2 Titanium 2

Constantan 2 Iron

2 NiSpan

C

2 Tungsten 2

Copper

14 Karma

2 Platinum

2 Zinc

14

Dumet

2 Kovar

2 Paliney

7

2

Electrode Face: Use a flat electrode face for most applications. Use a “domed” face if surface oxides

are a problem. If either of the work pieces is a wire, the diameter of the electrode face

should be equal to or greater than the diameter of the wire. If both work pieces are flat,

the face should be at least one-half the diameter of the electrodes.

Pencil point

electrodes reduce the overall quality of the welding process, and are not recommended.