APPENDIX A: TECHNICAL SPECIFICATIONS

MODEL 250DP DUAL PULSE

RESISTANCE WELDING POWER SUPPLY

990-280

A-15

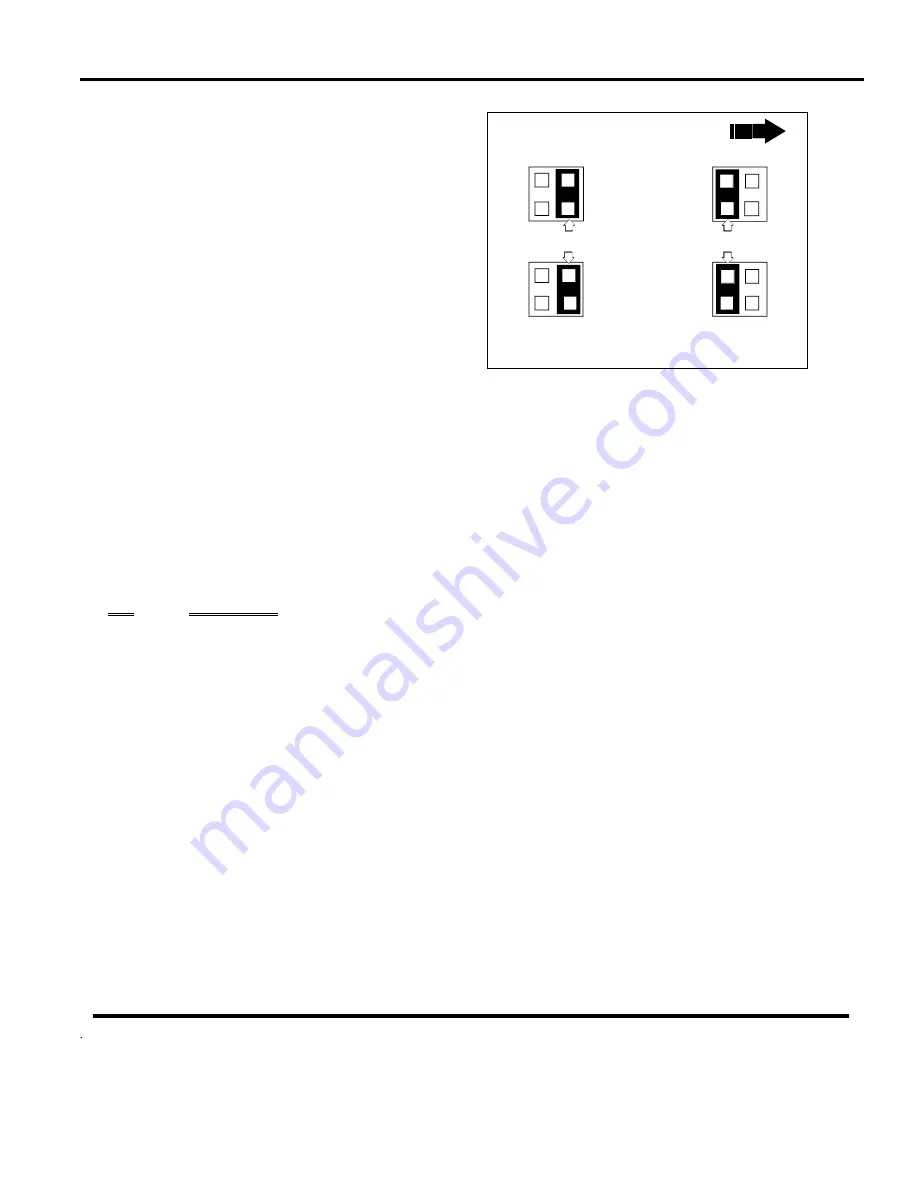

Air Valve Driver 2

The output of the AIR VALVE DRIVER 2

receptacle provides 24 VAC to power a second air

actuated weld head. Jumpers E10 and E11,

located near the lower right hand corner of the

control board must be moved to the correct

positions, as shown in figure A-4.

Air valve driver 2 is wired only for 24 VAC

through receptacle Pins 1 and 2. Pins 3 and 4 are

not provided. To provide power to Air valve

driver 2, move Jumpers E10 and E11 and program

WELD HEAD TYPE to DUAL AIR.

NOTE:

When air valve driver 2 is used, Relay 1

cannot be used.

Air Valve Driver Receptacles

The 4-pin receptacles located on the rear panel are AMP P/N 206430-1 (Unitek Peco PN 550-062). The

mating plug is an AMP 206429-1 (Unitek Peco PN 520-107), which uses a cable clamp, Amp 206358-2

(Unitek Peco PN 245-084). Air Valve Driver 1 is wired as follows:

Pin

Description

1

24

VAC

2

115 and 24 VAC return

3

115

VAC

4

Air head sensing - externally connected to Pin 2

NOTE:

Connect Pin 2 to Pin 4 on a non-Unitek Peco air actuated weld head.

Control Signals Connector

A 15-pin, sub-miniature D-type CONTROL SIGNALS connector, located on the rear panel, is provided for

the two relays and seven single pole inputs. The relays and switch inputs are used to:

x

Remotely select Weld Schedules 1 through 127

x

Remotely inhibit recharging the capacitor bank

x

Invoke an emergency stop condition to abruptly terminate the welding sequence.

E10

E11

E10

E11

Single Air Head

Dual Air Head

Jumpers

Jumpers

Rear of Unit

Figure A-4. Jumper Selection for

Air Valve Driver Control