OVERVIEW

7

Nur Hauptdokument

EN

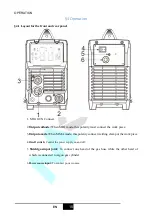

§2 Overview

§2.1 Brief Introduction

MIG SERIES

arc welding machine adopts the latest pulse width modulation (PWM)

technology and insulated gate bipolar transistor (IGBT) power module, which can change

work frequency to medium frequency so as to replace the traditional hulking work frequency

transformer with the cabinet medium frequency transformer. Thus, it is characterized with

portable, small size, light weight, low consumption and etc.

MIG SERIES arc welding machine uses Mix gas as shielded gas to realize gas shielded

welding, active gas

(

Ar+O

2

、

Ar+CO

2

)

as shielded gas to realize MAG welding and

inactive gas

(

Ar

)

as shielded gas to realize MIG welding.

MIG SERIES arc welding machine has automatic protection functions with intelligent to

over-voltage, over-current and over-heat. If any one of the above problems happens, the

alarm lamp on the front panel will be lighted and output current will be shut off automatically

to protect itself and prolong the equipment using life.

MIG SERIES Features:

1. Digital control system, real-time display the welding parameters;

2. High performance multifunction power source (MIG/MAG);

3. Waveform control, stable welding arc;

4. IGBT technology, low power dissipation;

MIG SERIES arc welding machine is suitable for all positions welding for various plates made of

stainless steel, carbon steel,

alloyed steel etc, which is also applied to pipe installment, mould mend,

petrochemical, architecture decoration, car repair, bicycle, handicraft and common manufacture.

MAG--Metal Active Gas Welding

MIG--Metal Insert Gas Welding

§2.2 Working Principle

The working principle of MIG SERIES arc welding machine is shown as the following

figure. single-phase 220V work frequency AC is rectified into DC

(

312V

)

, then is converted

to medium frequency AC (about 40KHz) by inverter device (IGBT), after reducing voltage by