Technical Documentation

KFG-P 2000

mk North America, Inc.

|

105 Highland Park Drive

|

Bloomfi eld, CT 06002

|

(860) 769-5500

|

www.mknorthamerica.com

©2022

|

Page 8

mk North America, Inc.

|

105 Highland Park Drive

|

Bloomfi eld, CT 06002

|

(860) 769-5500

|

www.mknorthamerica.com

©2022

|

Page 9

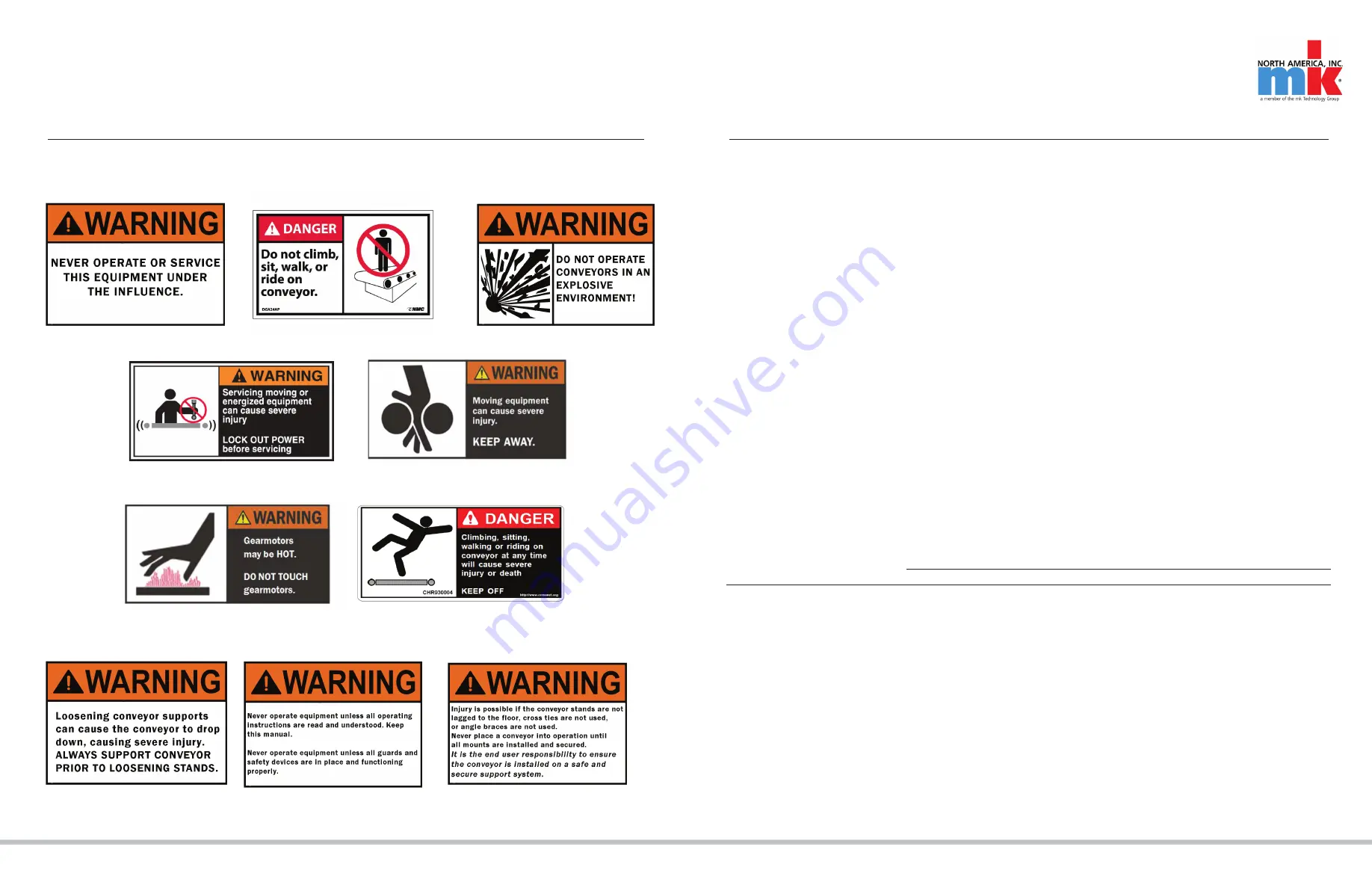

READ AND UNDERSTAND ALL OF THESE WARNINGS PRIOR TO OPERATING EQUIPMENT.

5

SAFETY REQUIREMENTS

6

WEAR ITEMS & MAINTENANCE FOR SPECIFIC DRIVE OPTIONS

6.1 Important Notes About Wear Items & Maintenance

9

6.2 KFG-P 2000 AC

10

6.3

KFG-P 2000 AF

12

6.4

KFG-P 2000 AS

14

6.5

KFG-P 2000 AU

16

6.1

Important Notes About Wear Items & Maintenance

The following information regarding life of the wear items and service or adjustment intervals of the functional

elements are only GUIDELINES. Conveyors are application-specifi c products whose life expectancy can vary

depending on their relative loads and speeds, and which can be signifi cantly infl uenced by environmental factors.

• All moving components and screw connections should be checked every 6 months.

• All safety-relevant components should be part of a regularly scheduled weekly inspection

• The proper function of these components must be confi rmed at all times.

• Do NOT operate conveyors if safety-relevant components are damaged or missing.

• All parts which contact the product should be cleaned weekly (example: belt).

• Belts require little special care. They are easily cleaned using lukewarm soapy water.

• Remove heavy grease coatings with ethyl alcohol.

• Blow off debris from belts with structured surfaces using compressed air.