MKS MultiGas High-Speed Gas Sampling Cart

Cart

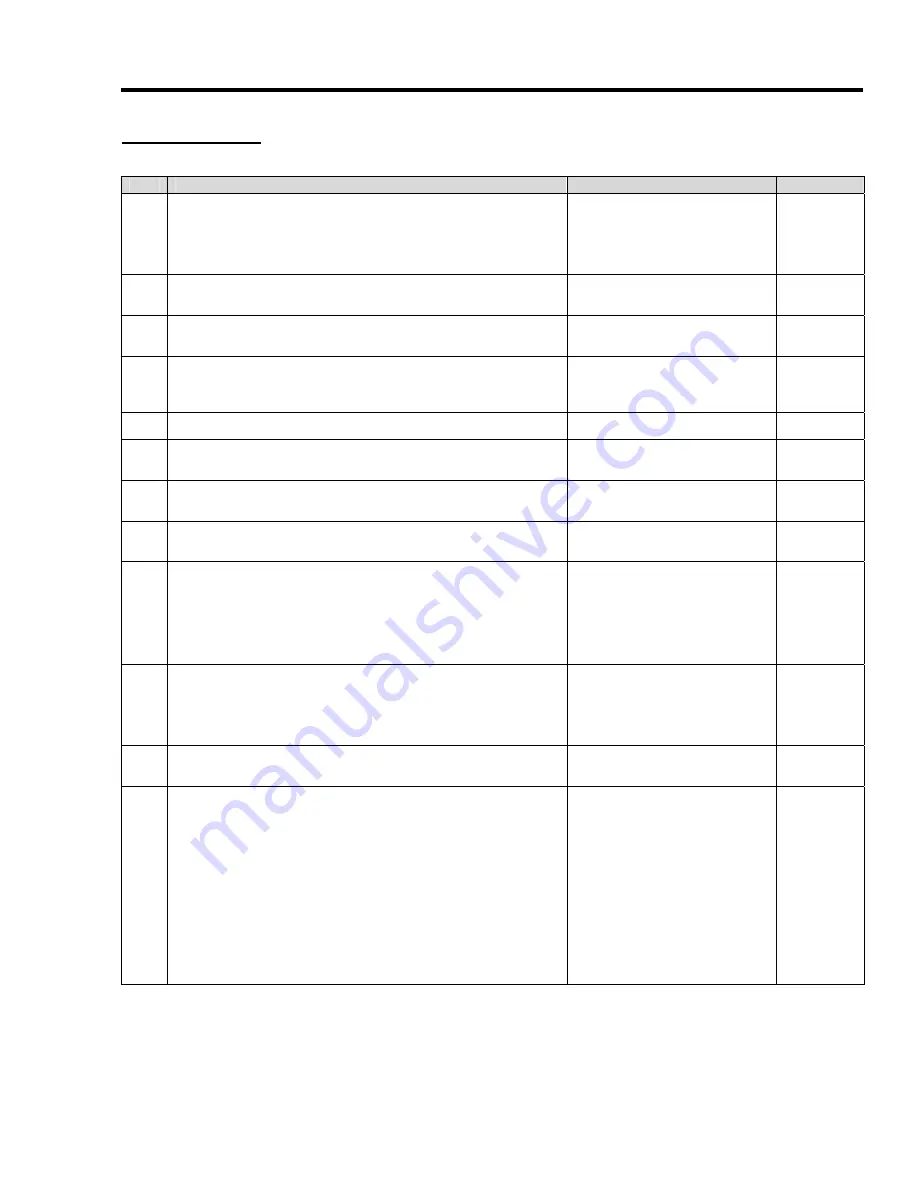

Daily

Use

STEP

ACTION

NOTES

COMPLETED

1.

The cart requires a 5-hour warm-up time. It is recommended to keep

the system powered-on at all times.

If starting with a cold system, see the “power up” section of this

manual.

2.

Turn off pumps when not in use.

The pumps may be turned off when

not sampling.

3.

Periodically drain water condensation from the Backpressure

reservoir. Drain valve found at the bottom of the reservoir.

4.

Verify temperature readings are stable:

HTD LINE 2: 191°C

HTD BOX: 191°C

5.

Verify that FM1 valve is in the full open position.

6.

Verify that the back pressure regulator is fully-clockwise to decrease

the backpressure through the system.

7.

Verify that the sample line is connected. Make sure the Swagelok

quick connect is properly seated.

8.

Turn the MV1 valve in the Span / N

2

position.

The valve handle moves left to

right in a lower arc.

9.

Turn MV2 to the N

2

position.

This is done to purge the MultiGas

gas cell with Nitrogen gas so the

daily checks can be performed and

a new background reading can be

taken. See MultiGas SOP for daily

checks.

10.

When Daily checks are completed and a new background has been

taken, turn the MV1 valve in the Sample position

When the MV1 valve is moved

from N

2

/Span to Sample all flow

through the MV2 is stopped.

11.

Verify that the HTD LINE 2 and HTD BOX temperatures are 191°C

then turn ON the Pump.

12.

Use the back pressure regulator to achieve the desired flow rate and

gas cell pressure. The pressure measured in the MG2000 should be at

1.0 atm ± 0.05atm.

If the pressure drops during the

sampling:

- The filter may be coated with

particulate

- Issue with the pumps, check to

see if both pumps

are running. Check front and

rear cowling to see

if the fan is spinning.

- Restriction in the sample line

Installation and Use Manual 2011 APRIL 2 Rev. 1.5

32