937A Multi-Sensor System

A.1

Appendix A: Installing

a Series 937A Sensor

The Series 937A Controller must be switched off

before connecting or disconnecting a cable from the

sensor or Controller.

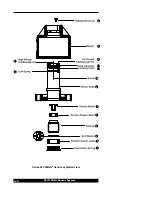

Cold Cathode Sensors

General

In a cold cathode sensor, gas molecules are ionized by a high voltage

discharge of electrons. Sensitivity is enhanced by a magnetic field. Cold

cathode sensors are rugged sensors without filaments to break or burn out.

The MKS inverted magnetron design includes an isolated collector, making

low pressure measurement less susceptible to contamination and allowing a

wider range of pressure measurement. The MKS IgniTorr™, an optional cold

cathode starting device initiates the ionization process in cold cathode

sensors, assuring UHV pressure readings in seconds (see Spare Parts and

Accessories, p. 71).

Locating a Cold Cathode Sensor

Locate a cold cathode sensor where it can measure process chamber or

manifold pressure. Install it away from pumps, gas sources, and strong

magnetic fields to give the most representative values.

Locate and orient a cold cathode sensor where contamination is least likely. If

it is installed directly above a diffusion pump, for example, oil vapor could

contaminate the cathode, anode, or other vacuum exposed components,

causing the calibration to shift.

Orienting a Cold Cathode Sensor

A cold cathode sensor can be installed with the body set in any direction.

Operating position does not affect accuracy.

Installing it with the vacuum port facing down is preferable as this helps

prevent contaminants from falling into the sensor.