Table 3. Slit Aperture Exposure Time Limits (minutes)

Table 4. Exposure Time Limits for Nickel Alloy and

Copper Slit Apertures (minutes)

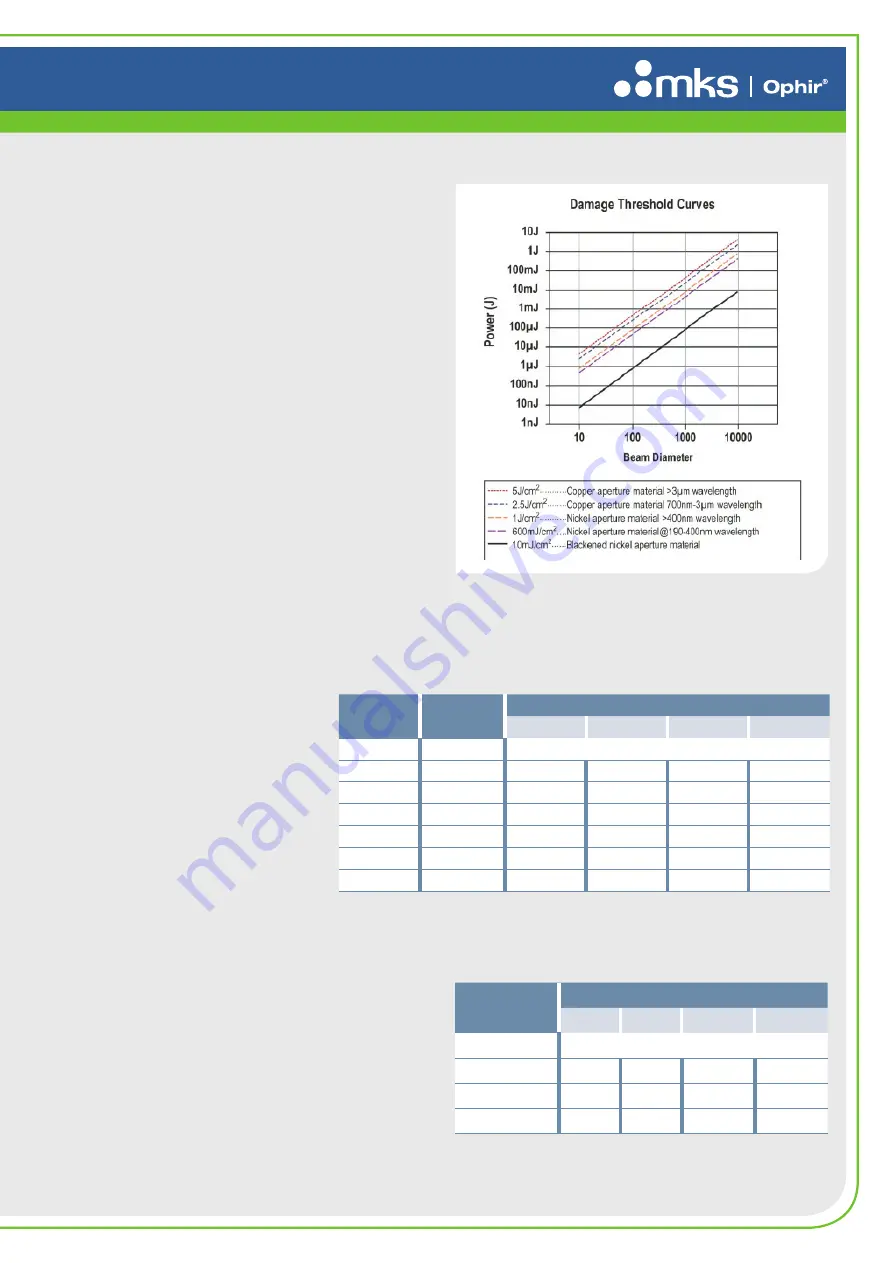

These values are also shown in the Pulsed Damage

Threshold curves given in figure 2. For pulsed lasers,

specifically those in the picosecond and femtosecond

regimes, it is very likely that the peak irradiance exceeds

damage thresholds but the fluence per pulse is very low.

In this case it is unlikely that instantaneous damage will

occur, but long term damage from micromachining is

likely. In this case,

Proceed with caution!

Long term Slit aperture Heating

exposure Limits

The long term exposure limits for slit aperture heating

are based on a heating model where all the laser power

goes into heating the slit aperture, and the time limit

that is necessary to reach the melting point of the slit

material, either nickel alloy or copper. When the slit

heats the Instantaneous Damage thresholds decrease.

The model provides conservative values for the time

limit because it neglects thermal conduction into the

drum. For reported times >5minutes, it is generally

safe to operate with continuous exposure, but caution

is advised. Exposure time limits for nickel alloy and

copper slit apertures are given in Table 3.

Long term drum Heating exposure Limits

The long term exposure limits for drum heating

are based on a heating model where all the laser

power goes into heating the drum, and the time

limit necessary to reach 100°C. The model provides

conservative values for the time limit because it

neglects convection cooling of the spinning drum. For

reported times >5minutes, it is generally safe to operate

with continuous exposure, but caution is advised.

Exposure time limits for nickel alloy and copper slit

apertures are given in table 4.

Wavelength

354.7

532

1064

10600

Material Power (W)

time (minutes)

Nickel

1

22

32

46

645

10

2.2

3.2

4.6

64.5

100

0.22

0.32

0.46

6.45

Copper

1

25

38

500

746

10

2.5

3.8

50

74.6

100

0.25

0.38

5

7.46

Wavelength

354.7

532

1064

10600

(Power W)

time (minutes)

1

300

300

425

1060

10

30

30

42.5

106

100

3

3

4.25

10.6

Figure 2. Pulsed Laser Damage Thresholds for nickel

alloy and copper slit apertures