Operation & Maintenance, Page

14

of

23

Section

3

– Revision 2.3

Where specified, on larger machines, adjustable cleaning combs may be fitted to minimise build-up of material between

the tooth rings, and to prevent recirculation of any product attached to the shafts. These cleaning combs will need periodic

adjustment to compensate for wear. This is achieved by removing packers as follows;

m

Check the actual cleaning comb clearance.

m

Remove the cleaning combs. Each cleaning comb is secured to the side plate by two bolts. Remove these bolts and

withdraw the cleaning comb from the side plate.

m

Remove necessary packers to give specified cleaning comb clearance. Thickness of packers to be removed is the

difference between actual cleaning comb clearance and the specified cleaning comb clearance.

m

Refit the cleaning combs into the side plates and move the packers from the ‘inside’ of the pyramid to the ‘outside’

and bolt into position using existing bolts. These bolts must then be re-torqued.

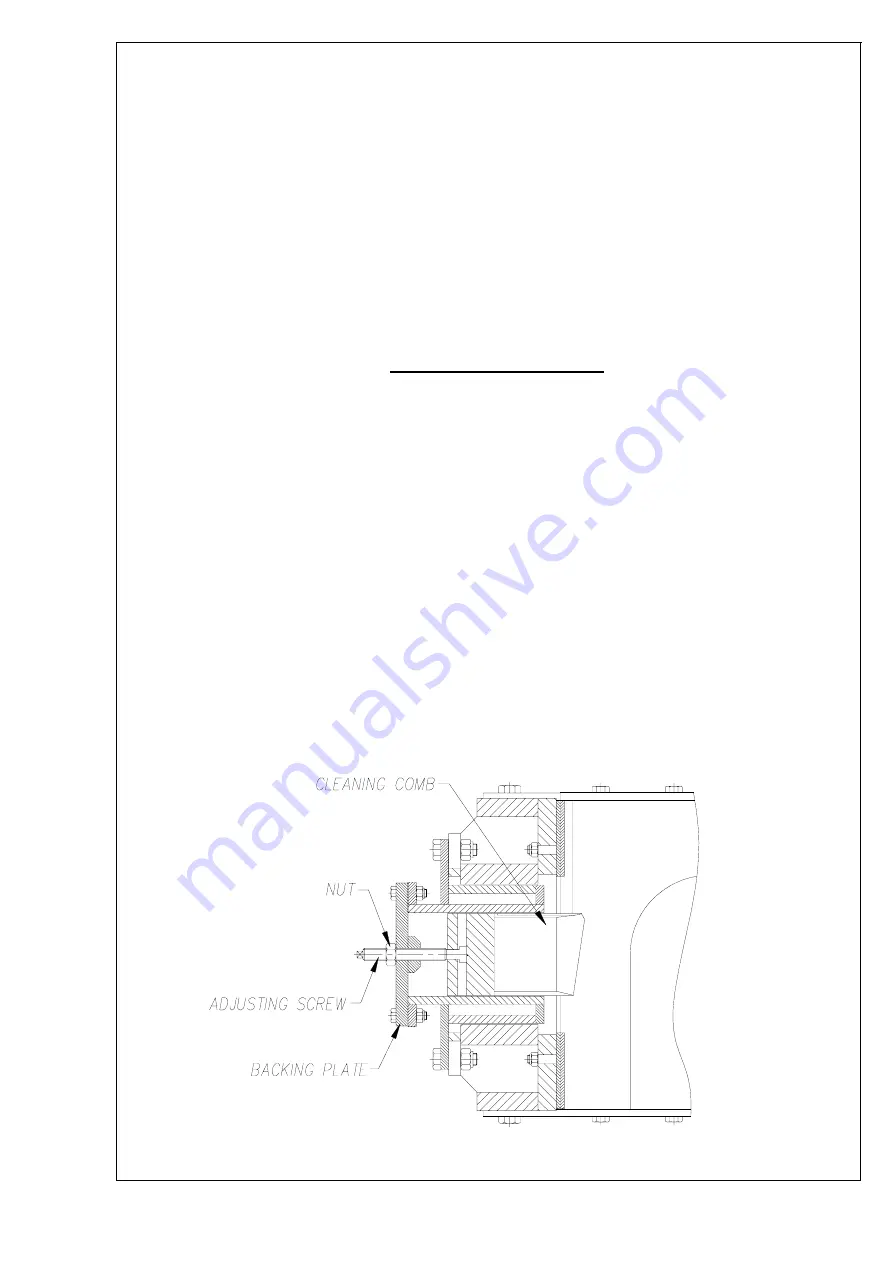

Screw Adjustable Type:

On smaller segment machines, adjustable cleaning combs &/or clay cleaners may be fitted.

Adjustment is carried out as follows;

m

Check the actual cleaning comb clearance.

m

Loosen the nut securing the adjusting screw to the backing plate.

m

Using the adjusting screw, move the cleaning comb into the desired position.

m

Re-tighten the nut, in accordance with MMD procedure T056.

Infill Box Adjustment

Where Infill boxes are fitted, the side combs mounted on the infill box can be adjusted, by adding or removing the packers.