23

❑

Pacer Z-42 Blue Threadlocker

❑

3mm Hex Wrench

❑

Adjustable Wrench

❑

Electric Drill

❑

3/32" & 5/32" Drill Bits

❑

Ruler

❑

Pencil

YOU'LL NEED THE FOLLOWING PARTS FROM THE KIT:

YOU'LL NEED THE FOLLOWING TOOLS AND SUPPLIES:

SECTION 12: ENGINE INSTALLATION

❑

(2) Engine Mounting Beams

❑

(4) M4 x 20mm Socket-Cap Screws

❑

(4) M4 x 25mm Socket-Cap Screws

❑

(4) M4 Lock Nuts

❑

(12) M4 Flat Washers

❑

(1) Spinner Assembly w/Backplate & Screws

STEP 1: INSTALLING THE ENGINE MOUNTING BEAMS

✦

✦

✦

✦

✦

IMPORTANT

✦

✦

✦

✦

✦

The following procedures outline the installation of a four-stroke engine. If you are installing a two-stroke

engine, the installation procedures are the same. The Magnum XL .70RFS engine is shown.

The mounting holes in the firewall are prespaced to fit the Magnum XL .61ARNV two-stroke engine and the Magnum XL .70RFS

four-stroke engine. If you are using a different size engine, such as the XLS .52A two-stroke engine or the XL .61RFS four-stroke

engine, you will have to modify the spacing of the mounting holes. This can be done by removing the blind nuts and gluing pieces

of hardwood dowel into the existing holes. You can then redrill the holes to fit your engine's width and reinstall the blind nuts.

Note that the engine is mounted inverted to fit properly within the cowling and to allow the muffler to exit the side of the fuselage.

❑

Install the two engine mounting beams onto the firewall, using four

M4 x 20mm socket-cap screws and four M4 flat washers. Tighten the

screws firmly to hold the engine mounting beams securely in place.

☞

Blind nuts have been preinstalled into the back of the firewall to

thread the screws into. We suggest applying Blue Threadlocker to the

screws to prevent them from loosening during flight.

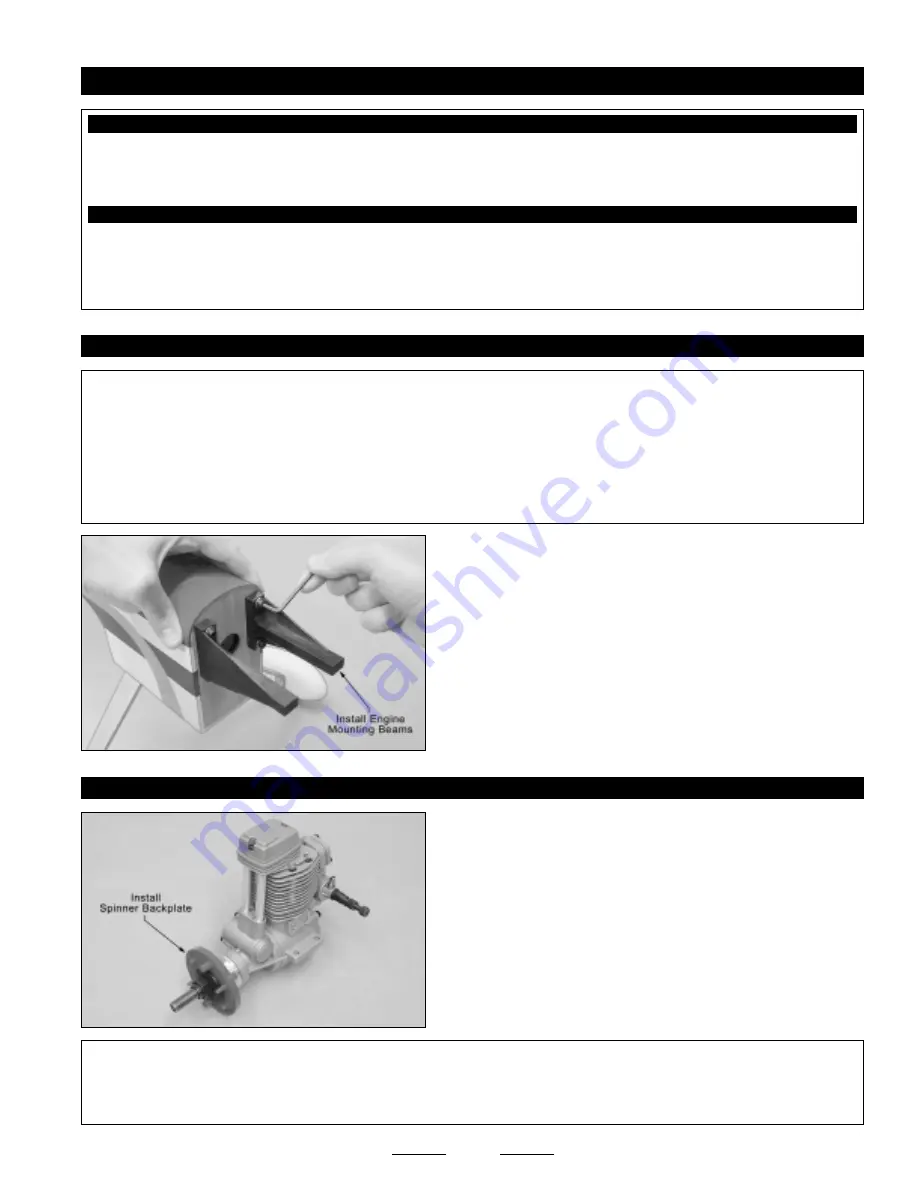

STEP 2: ALIGNING AND INSTALLING THE ENGINE

❑

Remove the muffler assembly, high speed needle valve and choke

lever (if applicable) from your engine and set them aside.

❑

Install the spinner backplate onto your engine's crankshaft, using

the propeller washer and nut included with your engine.

☞

Depending on the diameter of your engine's crankshaft, you may

need to enlarge the diameter of the hole in the spinner backplate to fit.

Use a drill bit or a propeller reamer to do this.

✦

✦

✦

✦

✦

IMPORTANT

✦

✦

✦

✦

✦

So that the cowling will line up properly when it's installed later, the engine must be spaced out correctly from

the firewall. The distance from the firewall to the back of the spinner backplate should be 4-1/2". This measurement is the same

whether you're installing a two-stroke engine or a four-stroke engine. This measurement will allow a 1/16" wide gap between the

front of the cowling and the spinner backplate, and allow the cowling to overlap the fuselage approximately 1/4".

Continued On Next Page

☛

☛

☛

☛

☛

Summary of Contents for Magic Formula 3D ARF

Page 46: ...46 ...