41

Before adjusting the control throws and flying your new Magic Formula 3D ARF, there are some points about the airplane's setup

that you should be aware of. We strongly suggest following these suggestions to get the most enjoyment out of your airplane.

Because of the large control surfaces, it is imperative that the aileron and elevator hinge gaps be sealed. Failure to do this can lead

to control surface flutter, which can cause your airplane to crash. Sealing the hinge gaps will also provide crisper control response

and the airplane will track straighter and fly truer, making trimming much easier.

☞

While the elevator and aileron hinge gaps should be sealed, it's not necessary to seal the rudder hinge gap, although you

certainly could if you wanted to.

Hinge gaps can be sealed using heat-shrink covering material or clear vinyl tape. To seal the hinge gaps using heat-shrink covering

material, follow these steps:

❑

Cut a piece of covering material 1" wide and the same length as the hinge gap you're going to seal.

❑

Fold the length of covering material in half lengthwise so that there is a sharp crease down the middle of the covering material.

☞

The hinge gap sealing material should be applied to only the bottom of the hinged surfaces. It is not necessary to seal both the

bottom and the top.

❑

Remove the protective backing from the covering material. With the control surface fully deflected in the "UP" position, place the

length of covering material over the hinge line (on the bottom), making sure that the crease is pushed completely down into the hinge line.

SECTION 23: AIRCRAFT SETUP INFORMATION

SEALING THE HINGE GAPS

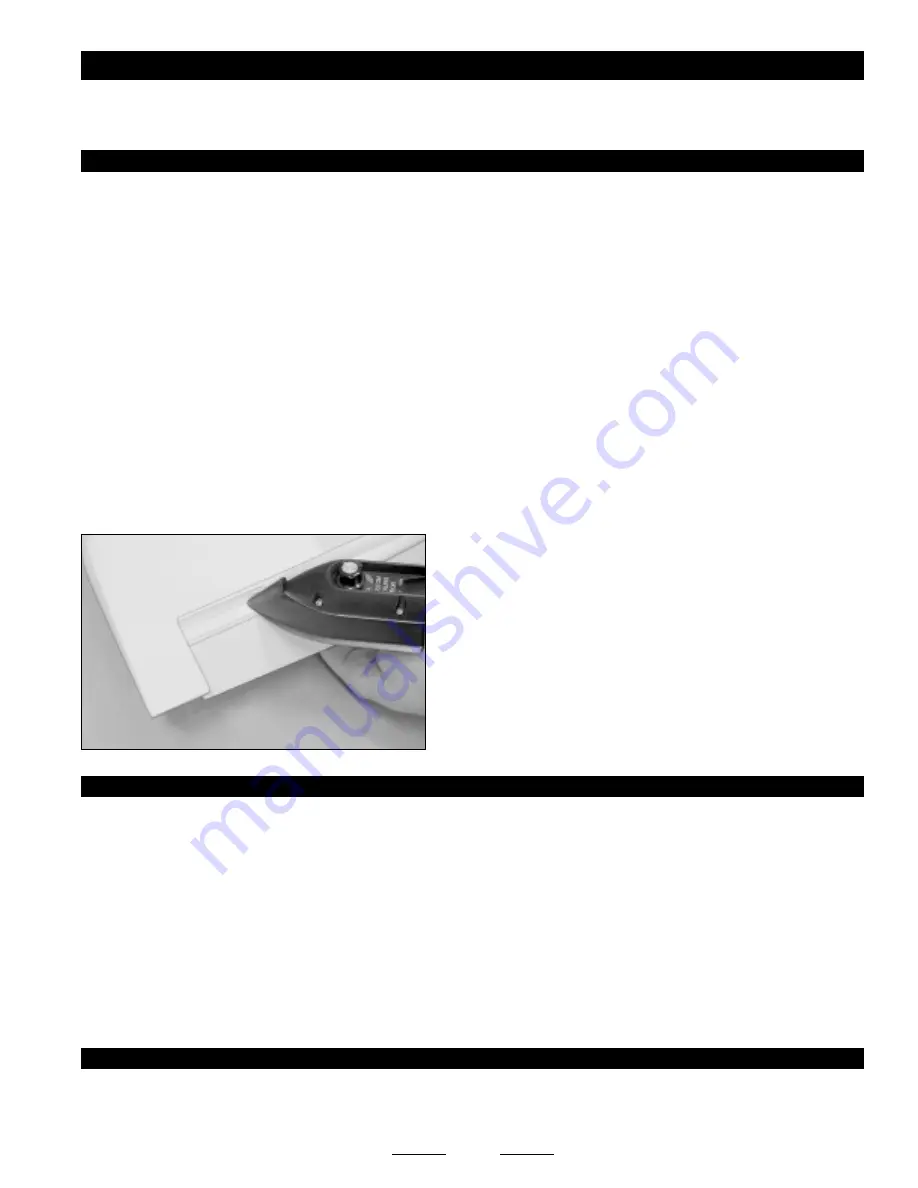

❑

With the control surface fully deflected in the "UP" position, use a

heat sealing iron to carefully adhere the covering material to both the

trailing edge of the flying surface and the leading edge bevel of the

control surface. Use a modeling knife to trim the excess covering

material flush with both surfaces.

❑

Pivot the control surface up and down several times to check for free

movement. The control surface should be able to smoothly pivot

completely up and completely down, without interference from the hinge

gap sealing material.

If you don't maintain the proper mechanical advantage on the control surfaces, control surface flutter may result, which can cause

your airplane to lose control and crash. Mechanical advantage refers to the distance that the pushrod attachment points (pivot

points) are from the servos and the control surfaces.

●

Keeping the pushrods as close to the center of the servo arms as possible will increase the servo's resolution. What this means

is that when you move the control sticks on the transmitter, the servo arms will have to travel farther to achieve the desired amount

of control input. This makes the resolution higher, therefore causing the control surface deflection to be more precise. We don't

recommend moving the pushrods any farther away from the center of the servo arms than absolutely necessary.

●

Keeping the pushrods as far away as possible from the control surfaces is better than moving them closer. The mechanical

advantage is greatly reduced the closer the pushrods are moved toward the control surfaces. We don't recommend moving the

pushrods any closer to the control surfaces than absolutely necessary.

It is very important that you understand throttle management. Basically, this means no full throttle dives. Full throttle

dives should be avoided so as not to cause control surface flutter and/or airframe failure. When the nose of the airplane

drops, decrease the throttle, just as in full-scale aerobatics.

CONTROL SURFACE LINKAGES

THROTTLE MANAGEMENT

Photo Shown May Look Different

Than Actual Model

Summary of Contents for Magic Formula 3D ARF

Page 46: ...46 ...