Page 10

Page 11

STeP 2A: iNSTAlliNG The MoTor - WiTh bolT-oN ThreAded ProPeller AdAPTer

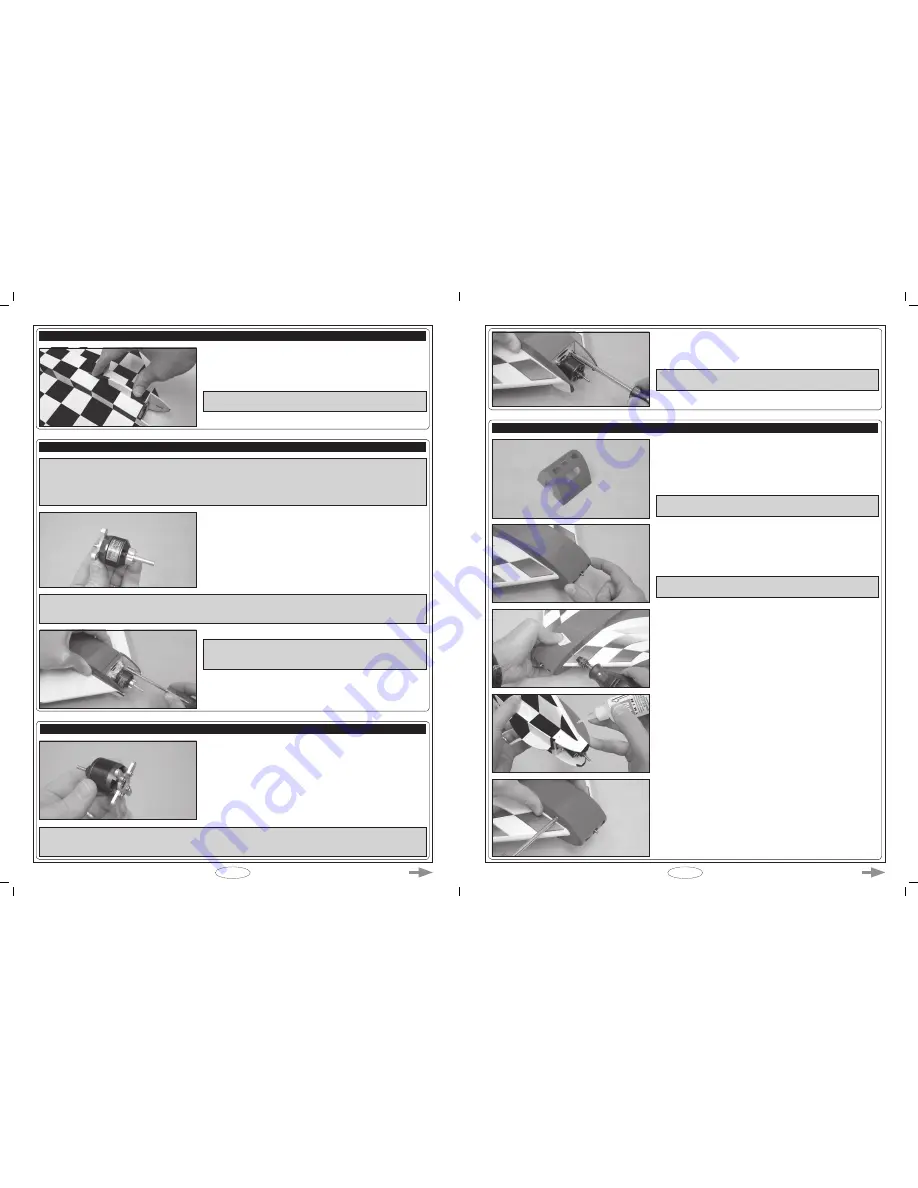

STeP 1: iNSTAlliNG The lANdiNG SKid

q

Cut away the covering material from over the landing skid mounting slots in

the bottom of the wing, then test-fit and glue the landing skid firmly into place,

using a generous amount of thick C/A.

IMPORTANT

Make sure to cut away the covering material from over

the gluing surfaces to ensure a strong bond.

IMPORTANT

Two different types of motor are showed installed. The first type shown in step 2A is an outrunner motor that uses a

backplate mount and a bolt-on threaded propeller adapter. This type of motor requires using the two plywood spacer plates and four

18mm long machine screws to install. The second type shown in step 2B is an outrunner motor that uses a backplate mount and a

slide-on propeller adapter. This type of motor does not require any spacer plates and uses four12mm long machine screws to install.

Please follow the step that matches the motor type that you're using.

q

Install the propeller adapter and the backplate mount (both included with

your motor) onto your brushless outrunner motor, following the procedures in

your motor's user's guide.

q

Install your motor, using two plywood spacer plates, four M3 x 18mm

machine screws and four M3 flat washers, making sure to tighten the machine

screws firmly.

IMPORTANT

The two plywood spacer plates are provided to push

your motor out far enough so that the front of the propeller adapter is

approximately 1/16" (1.6mm) in front of the fuselage sides.

IMPORTANT

The preinstalled blind nuts in the firewall are spaced to fit a majority of 4-hole radial backplate mounts of motors

within the specifications of the aircraft. If your motor's backplate mount uses a different mounting hole pattern, you will need to drill new

mounting holes and reinstall the blind nuts to match.

STeP 2b: iNSTAlliNG The MoTor - WiTh Slide-oN ProPeller AdAPTer

IMPORTANT

The preinstalled blind nuts in the firewall are spaced to fit a majority of 4-hole radial backplate mounts of motors

within the specifications of the aircraft. If your motor's backplate mount uses a different mounting hole pattern, you will need to drill

new mounting holes and reinstall the blind nuts to match.

q

Install the backplate mount (included with your motor) onto your brushless

outrunner motor, following the procedures in your motor's user's guide.

STeP 3: iNSTAlliNG The CoWliNG

q

When satisfied with the fit and alignment, hold the cowling securely in place,

using a couple of pieces of masking tape.

q

Drill two 1/16" (1.6mm) diameter pilot holes through each side of the

cowling for the wood screws. Position one pilot hole centred between the top

of the cowling and the top of the wing, and one pilot hole centred between the

bottom of the cowling and the bottom of the wing. All four pilot holes should be

1/8" (3mm) in front of the back edge of the cowling.

q

Slide the cowling onto the front of the aircraft and align it. When aligned

properly, the hole in the middle of the cowling should be centred around the

motor shaft and the back of the cowling should fit flush against the surface of

the aircraft. The cutouts in the side of the cowling should fit over the contour

of the wing leading edges, too.

IMPORTANT

You may need to cut a notch in the bottom of the cowling

to fit around the front of the landing skid.

q

Cut out the back of the cowling along its base, making sure to cut the back

edge straight.

q

Using the moulded scribe lines as a guide, cut out the sides of the cowling to

clear the wing leading edges, then cut out the holes in the front and the bottom

of the cowling for the propeller adapter and the three cooling intake holes.

IMPORTANT

Depending on the motor that you're using, you may need

to cut out more of the front of the cowling than shown.

q

Remove the cowling and apply a couple of drops of thin C/A into the four

pilot holes and allow the C/A to fully cure.

q

Install the cowling, using four M2 x 10mm washer-head wood screws.

q

Install your motor, using four M3 x 12mm machine screws and four M3 flat

washers, making sure to tighten the machine screws firmly.

IMPORTANT

It's not necessary to use the two plywood spacer plates

with this type of motor.