11

MCP15-500.9

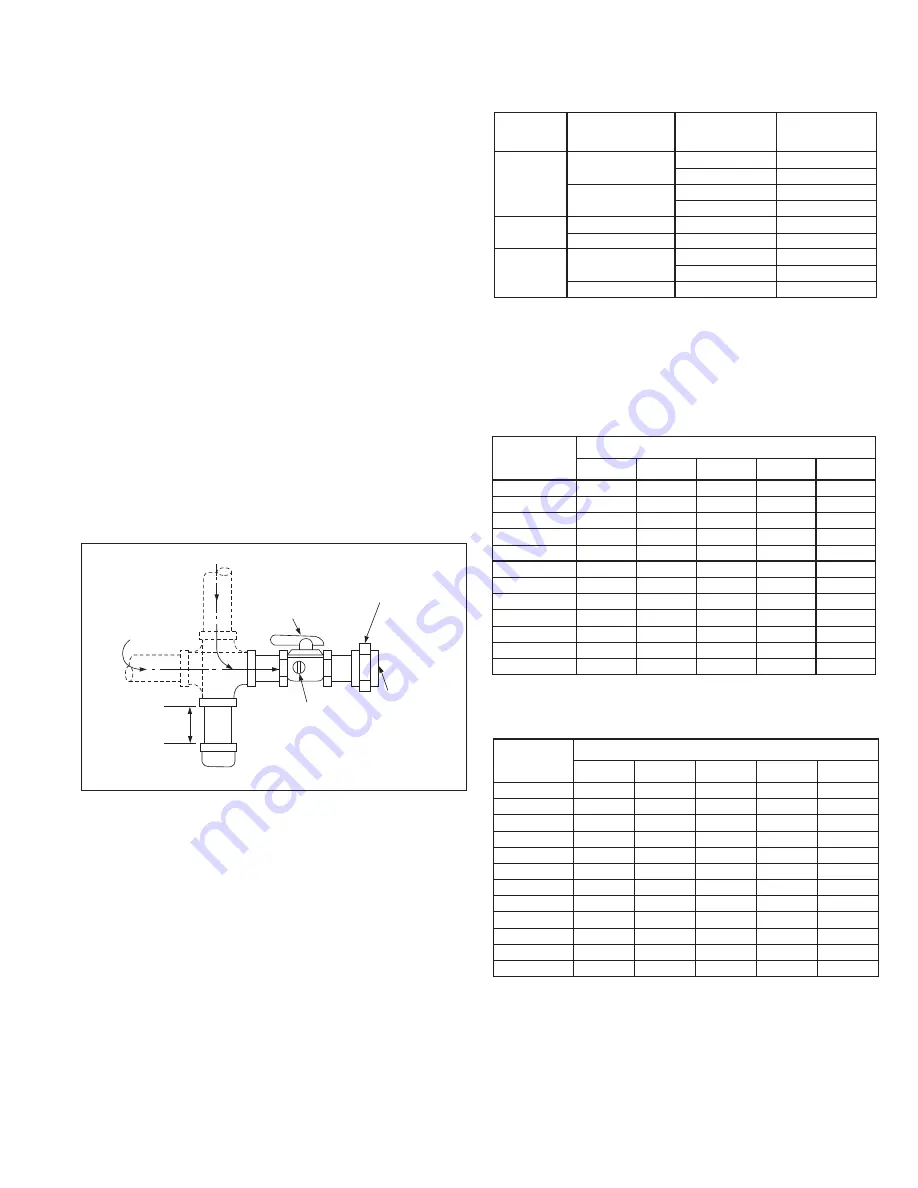

Figure 11.1 - Recommended Sediment Trap/Manual

Shut-off Valve Installation

GAS

SUPPLY LINE

GAS

SUPPLY LINE

GROUND JOINT

UNION WITH

BRASS SEAT

MANUAL GAS

SHUT-OFF VALVE

3"

MIN.

SEDIMENT

TRAP

PLUGGED

1/8" NPT TEST

GAUGE CONNECTION

TO GAS

CONTROLS

j

Valve is in the “OFF” position when handle is perpendicular to pipe.

GAS CONNECTIONS

W.C. for propane gas and should not drop below 6.0" W.C.

when the unit is operating. When sizing the inlet gas pipe

diameter, make sure that the unit supply pressure can be

met after the 0.3" or 0.5” W.C. has been subtracted. If the

pressure drop is too high, refer to NFPA 54 National Fuel

Gas Code for other pipe capacities.

3. The gas piping is to enter the unit from the side (refer to

the unit dimensions). B- and C-Cabinet sized units include

a hole and grommet in the side of the casing for side gas

piping entry. D-Cabinet sized units include two holes with

grommets for side pipe entry. Install a ground joint union

with brass seat and a manual shut-off valve external of the

unit casing, and adjacent to the unit for emergency shut-

off and easy servicing of controls, including a 1/8" NPT

plugged tapping accessible for test gauge connection (see

Figure 11.1). Verify the manual shut-off valve is gas tight

on an annual basis.

4. Provide a sediment trap before each unit in the line where

low spots cannot be avoided (see Figure 11.1).

5. When Pressure/Leak testing pressures above 14" W.C.

(1/2 psi), close the field installed shut-off valve, disconnect

the appliance and its combination gas control from the gas

supply line, and plug the supply line before testing. When

testing pressures 14" W.C. (1/2 psi) or below, close the

manual shut-off valve on the appliance before testing.

Table 11.1 - Gas Heating Piping Connection Sizes

j

Units with Natural Gas heating option have model nomenclature Digit 17 = 2

or 3. Units with Propane (LP) Gas heating option have model nomenclature

Digit 17 = 5 or 6.

k

C-Cabinet units consist of two furnaces that together total the value shown in

Table 11.1.

l

D-Cabinet units consist of two furnaces that together total the value shown in

Table 11.1 for sizes up to 800,000 Btu/hr. For sizes over 800,000 Btu/hr, the

unit consists of four furnaces that together total the value shown in Table 11.1.

n

Capacities based on gas pressure up to 14" W.C. through Schedule 40 pipe

with a pressure drop of 0.5" W.C. for Propane gas with a specific gravity of

1.50.

Table 11.2 - Natural Gas Pipe Capacities (MBH)

m

Pipe Length

(ft)

Nominal Gas Pipe Diameter

1”

1-1/4”

1-1/2”

2”

2-1/2”

10

540

1,113

1,659

3,203

5,103

20

371

762

1,145

2,195

3,507

30

298

612

917

1,764

2,814

40

255

524

784

1,512

2,405

50

226

464

695

1,344

2,132

60

205

420

630

1,218

1,932

80

175

360

540

1,038

1,659

100

155

319

478

921

1,470

125

138

282

423

816

1,302

150

125

256

384

739

1,176

175

114

235

353

680

1,082

200

107

219

329

632

1,008

Pipe Length

(ft)

Nominal Gas Pipe Diameter

1”

1-1/4”

1-1/2”

2”

2-1/2”

10

1,150

2,350

3,520

6,790

10,800

20

787

1,620

2,420

4,660

7,430

30

632

1,300

1,940

3,750

5,970

40

541

1,110

1,660

3,210

5,110

50

480

985

1,480

2,840

4,530

60

434

892

1,340

2,570

4,100

80

400

821

1,230

2,370

3,770

100

372

763

1,140

2,200

3,510

125

349

716

1,070

2,070

3,290

150

330

677

1,010

1,950

3,110

175

292

600

899

1,730

2,760

200

265

543

814

1,570

2,500

Table 11.3 - Propane Gas Pipe Capacities (MBH)

n

m

Capacities based on gas pressure up to 14” W.C. through Schedule 40 pipe

with a pressure drop of 0.3” W.C. for Natural gas with a specific gravity of 0.60.

Example:

A D-Cabinet unit with Digit 17=2 (Natural Gas) and Digit 18=Q (800MBH)

is installed in a location requiring 50 feet of gas supply pipe. What is the

minimum pipe diameter required for the supply pipe?

From Table 11.2, 50 feet of 1-1/2” pipe has a capacity of 695MBH which may

result in too significant of a pressure drop. The 2” pipe has a capacity of

1,344MBH which is sufficient for a unit with an 800MBH Natural Gas heat option.

Cabinet Size

(Digit 6)

Gas Type

(Digit 17)

j

Furnace Size

(MBH)

Gas Connection

Size

B

Natural Gas

Below 200

1/2”

200 and Larger

3/4”

Propane (LP) Gas

Below 300

1/2”

300 and Larger

3/4”

C

k

Natural Gas

All

1”

Propane (LP) Gas

All

3/4”

D

l

Natural Gas

Below 850

1” (Qty 2)

850 and Larger

1-1/2” (Qty 2)

Propane (LP) Gas

All

1” (Qty 2)