4-522.4

13

oPeration

6. Shut unit off and connect a pressure gauge to the pressure

gauge port on the fuel unit. When the unit is turned on, the

pressure should be 130 +/- 2psi for POR100 and 145, 100

+/- 2psi for POR 185. If pressure adjustment is necessary,

adjust pressure with screwdriver or Allen wrench. See

Figure 7.2 and 8.1.

7. After the oil pressure is set, readjust the air bands to

produce just a trace of smoke which is slightly less than #1.

From the trace point, open the air bands to give 0 (zero)

smoke. A carbon dioxide (CO2) check at this smoke level

should read 11.5 to 12.5%. CO2 levels above 12.5% are not

recommended as sooting could occur as conditions and fuel

var y.

8. The fan and limit switch is factory set at a high limit

temperature of 210°F. Do not change this setting. It is

also factory set to turn on the fan at 120°F and turn it off

at 90°F. These settings may be changed by following the

control manufacturer’s instructions packed in the literature

envelope attached to the unit. Since the fan and limit control

is operated by a thermal switch, not the thermostat, residual

heat in the heat exchanger can cycle the fan on after the

thermostat has been satisfied.

9. Adjust the air deflector blades for desired heat distribution.

All horizontal blades should be kept open a minimum of 30°

as measured from vertical.

10. Run the unit through several cycles by raising and lowering

the thermostat setting to assure proper sequence of

operation.

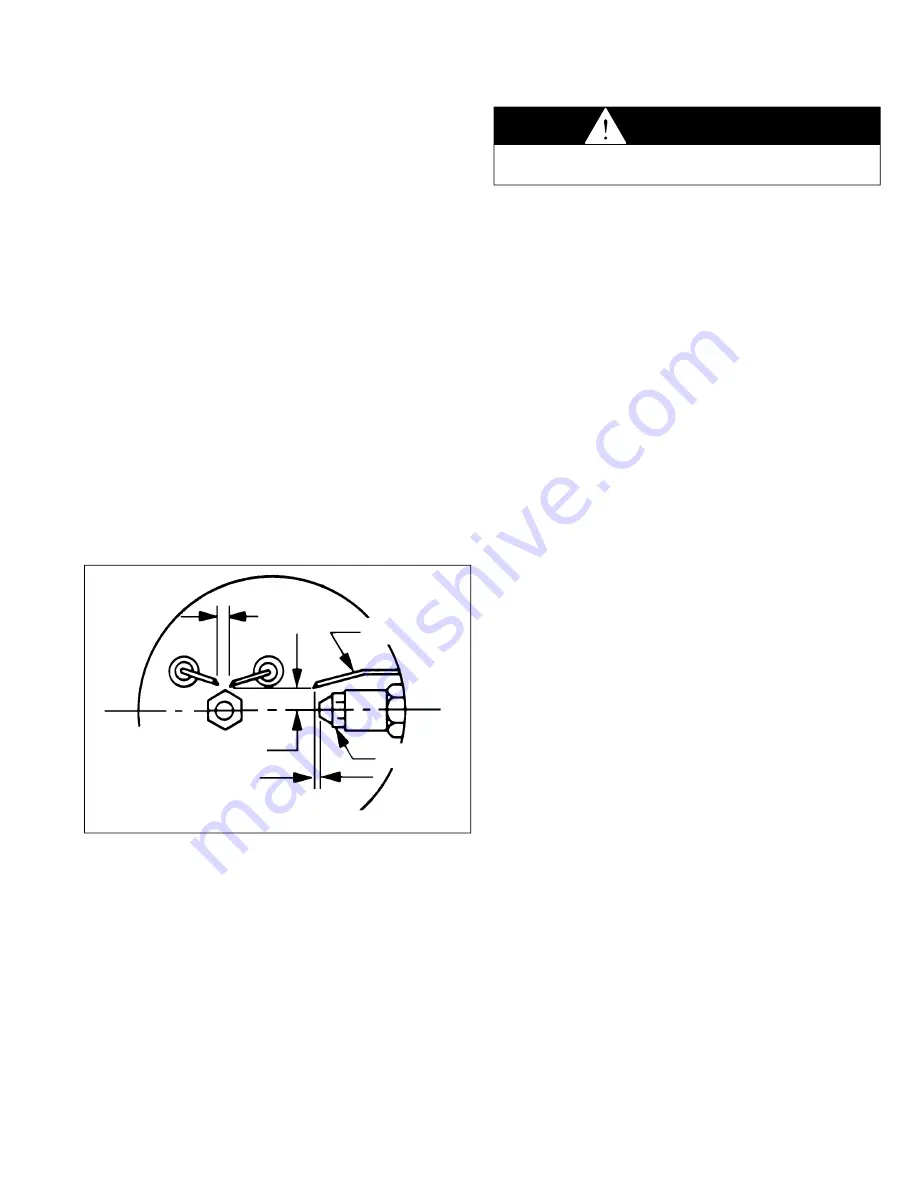

figure 13.1

electrode gap, Beckett Burner

service instructions

routine unit maintenance

Under average conditions, it is recommended that unit heaters

be serviced at least once a year and checked out prior to the

heating season. In excessively dirty atmospheres, service

should be performed more often.

1. Disconnect power supply to the unit before performing any

of following maintenance of inspection procedures.

2. Tighten fan guard and motor bracket. Check fan for proper

clearance, free rotation, and firm connection to motor shaft.

Clean fan blade with detergent or compressed air.

3. Fan motor is permanently lubricated for normal operation.

Under severe conditions, lubricate with non-detergent SAE

20 motor oil.

4. Routine cleaning of the unit casing and louvers is

recommended to remove dirt, grease, or corrosive

substances that may damage the finish. Rusted or corroded

spots on the louvers or casing should be sanded and

repainted. To remove, push louvers against retaining coil

spring and pull out at opposite tapered end.

5. With louvers removed inspect inside of heat exchanger with

a flash light through the flame inspection port. Check for

soot deposits, damaged fire pot, heat exchanger or burner

head.

6. If there is a heavy soot-coating inside heat exchanger, it

should be drawn out with a vacuum cleaner after removing

the front access panel. Care must be taken not to damage

the fire pot during the cleaning operation.

7. Replace fuel oil filter elements at unit heater and at

booster pump to prevent contamination of the fuel unit and

atomizing nozzle.

8. Check entire electrical system before every heating season.

9. Make sure gate on barometric draft control swings freely.

oil Burner service

The electric motor-driven burner assembly supplied with the

Modine oil-fired unit heaters lifts, pressures and atomizes a

continuous charge of fuel oil with a forced draft of combustion

air into the heat exchanger fire pot where it is ignited by

sparking electrodes. Burner components that will require

inspection and service include the burner motor, blower wheel

primary control, nozzle, nozzle, electrodes, and the fuel unit.

The burners utilize either a Honeywell, or White-Rodgers

primary control and cad cell and either a Webster or a Suntec

fuel unit. Refer to manufacturer’s instructions packed with each

unit.

CAUTION

Service procedures should only be performed by a qualified

oil serviceman.

5/16" ABOVE C L

NOZZLE

ELECTRODE

5/32" GAP

1/16"