4-522.4

3.

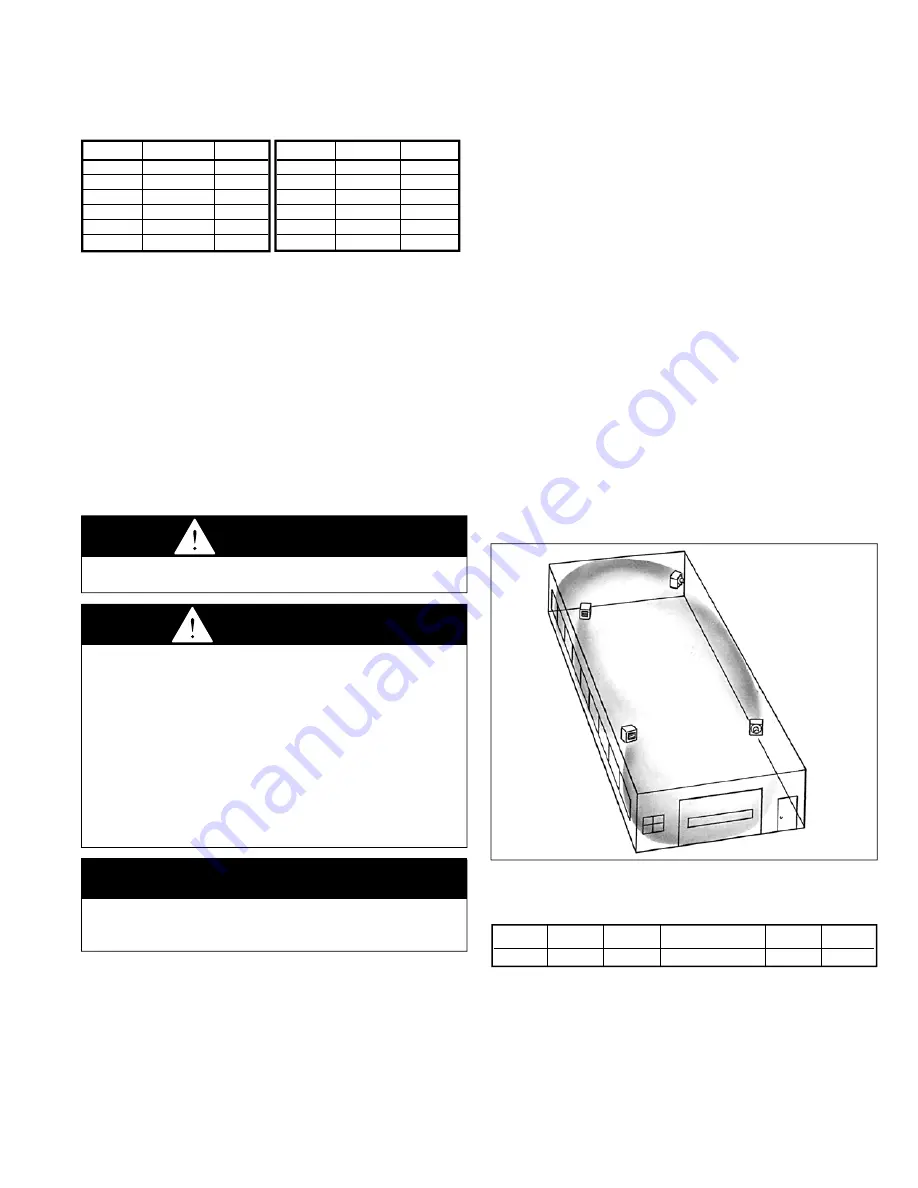

In multiple unit installations, arrange units so that each

supports the air stream of the next unit, thus creating

circulatory air movement in the area. See Figure 3.1. A large

portion of the heated air should be directed toward the side

of the building exposed to prevailing winds.

4.

When locating units, it is important to consider that the

exhaust vent piping must be connected to the outside

atmosphere.

5.

Be sure the structural support at the unit location site is

adequate to support the weight of the unit. For proper

operation the unit must be installed in a level horizontal

position.

6.

Do not install units in locations where the flue products

can be drawn into the adjacent building openings such as

windows, fresh air intakes, etc.

7.

Be sure that the minimum clearances to combustible

materials and recommended service clearances are

maintained. Units are designed for installation on with the

minimum clearances shown in Table 3.2.

8.

Do not install units in locations where gas ignition system is

exposed to water spray, rain, or dripping water.

9.

Mounting Height (measured from bottom of unit) at which

unit heaters are installed is critical. Refer to mounting height

information and heat throw data on page 17 of this manual.

The maximum mounting height for any unit is that height

above which the unit will not deliver heated air to the floor.

figure 3.1

typical unit locations

table 3.2

combustible material and service clearances

all model sizes

3

general information

Install and wiring of these oil-fired unit heaters must conform to

all applicable local codes, the National Electric Code, and NFPA

No. 31 “Installation of Oil Burning Equipment” by the National Fire

Protection Association. Installation of these unit heaters should

only be performed by a qualified oil serviceman.

1. These unit heaters are listed by Underwriters Laboratories,

Inc., with components as furnished.

2. Fuel oil grade No. 1 or 2, with a flash point not less than 100°F,

is approved for these unit heaters as specified by (ASTM)

D396-73 Standard Specification for Fuel Oils, or the Canadian

Government Specification Board, 3-GP-28, (American Society

for Testing and Materials).

si (metric) conversion factors / unit location

CAUTION

1. Do not locate units in tightly sealed rooms or small

compartments (commonly referred to as confined spaces)

without provisions for adequate combustion air and

venting. Combustion air must have access to the confined

space through a minimum of two permanent openings in

the enclosure, at least one near the bottom. They should

provide a free area of not less than one square inch per

1,000 BTU/Hr input rating of all units in the enclosure with

a minimum of 100 square inches for each opening,

whichever is greater.

2. When oil-fired unit heaters are to be installed in areas

having negative pressure (for example - a space with

exhaust fans) a power venter is recommended.

IMPORTANT

To prevent premature heat exchanger failure, do not locate

ANY gas-fired appliances in areas where corrosive vapors (i.e.

chlorinated, halogenated or acid) are present in the atmosphere.

dANGER

Appliances must not be installed where they may be exposed

to potentially explosive or flammable atmosphere.

si (metric) conversion factors

table 3.1

unit location

location recommendations

1.

When location the furnace, consider general space and

heating requirements, availability of gas and electrical

supply, and proximity to vent locations.

2.

Unit heaters should be located so they discharge air nearly

parallel to exposed walls. Arrange units so they do not

blow directly at occupants. Interference of air streams by

columns, beams, partitions, or other obstructions should be

avoided as much as possible.

Top

Sides

Back

Front

Bottom

Flue

18”

18”

18”

Unobstructed

18”

18”

to convert multiply By to obtain

"W.C.

0.24

kPa

psig

6.893

kPa

°F

(°F-32) x 0.555

°C

inches

25.4

mm

feet

0.305

meters

CFM

0.028

m

3

/min

to convert multiply By to obtain

CFH

1.699

m

3

/min

Btu/ft

3

0.0374

mJ/m

3

pound

0.453

kg

Btu/hr

0.000293

kW/hr

gallons

3.785

liters

psig

27.7

"W.C.