STEP 4: FINISHING

TOP CAPPING CHANNEL

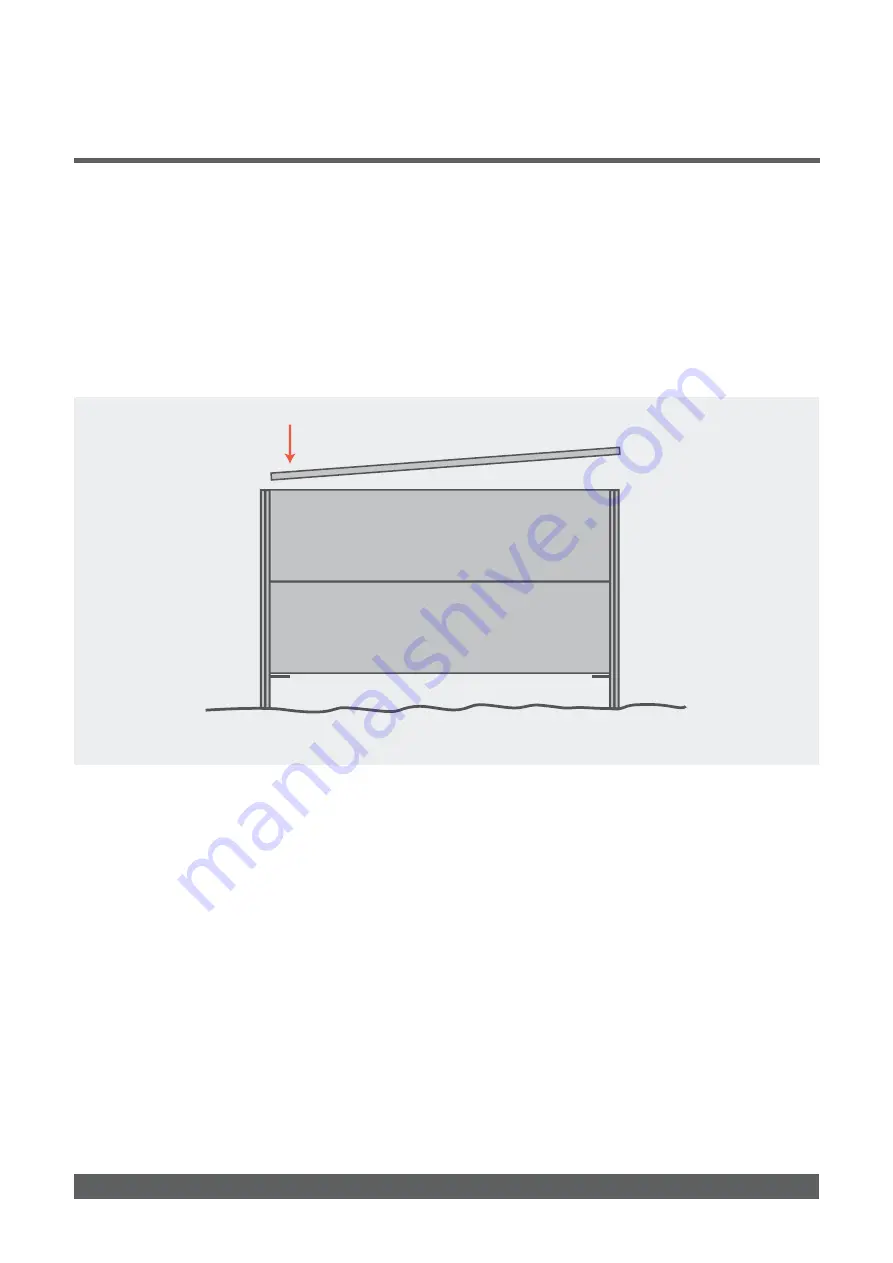

Once the top panel has been installed you can now install the top capping channel.

With a correctly spaced post, the capping channel will not need trimming to length. It will fit inside the post at

either end by approximately 5mm - 7mm from the face of the post. Should you need to cut a capping channel to

length, measure the inside dimension from post face to post face, and add 12mm.

NOTE: Apply a bead of liquid nails (FLEXIT or similar) to the inside radiuses of the channel before fitment.

16

SLIMWALL™ INSTALLATION GUIDE

Summary of Contents for Slimwall Classic Post

Page 1: ...INSTALLATION GUIDE SLIMWALL CLASSIC POST 90mm 90mm 810280SWC ...

Page 28: ...SWR1 ADDITIONAL SLIMWALL RETAINING PANEL 28 SLIMWALL INSTALLATION GUIDE ...

Page 29: ...SWR2 ADDITIONAL SLIMWALL RETAINING PANEL SLIMWALL INSTALLATION GUIDE 29 ...

Page 33: ...ADDITIONAL SLIMWALL RETAINING PANEL SLIMWALL INSTALLATION GUIDE 33 ...

Page 34: ...NOTES 34 SLIMWALL INSTALLATION GUIDE ...