MOHAWK MODEL LMF-12, TP-15,TP-16 & TP-18

8

INSTALLATION INSTRUCTIONS, CONT.

BLEEDING PROCEDURE

ENGAGE THE UP BUTTON ON THE POWER UNIT. OBSERVE THE

CARRIAGE. WHEN THE MAIN AND OFF SIDE CARRIAGES HAVE

REACHED FULL HEIGHT, CONTINUE TO RUN THE UNIT FOR 10

SECONDS.

RELEASE THE UP BUTTON AND WAIT ONE MINUTE, THEN HOLD

THE UP BUTTON AGAIN FOR 10 SECONDS. REPEAT THIS

PROCEDURE THREE TIMES (THIS WILL PURGE THE AIR FROM

THE HYDRAULIC SYSTEM)

NOTE

•

LISTEN FOR THE PRESSURE RELIEF VALVE. A NOTICEABLE

INCREASE IN POWER UNIT VOLUME THIS MAY INDICATE

THAT THE NUTS ON THE LIFTING RODS NEED TO BE

ADJUSTED. ADJUST THE NUTS EVENLY ON BOTH SIDES OF

THE CARRIAGE TO ALLOW THE CYLINDERS TO FULLY

STOKE AT THE TOP.

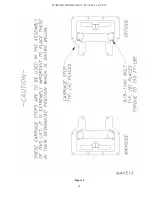

ASSEMBLE THE TWO HEIGHT ADAPTERS BRACKETS TO THE

BACK OF THE MAIN AND OFF SIDE POST USING THE FOUR 5/16

BOLT, WASHER & NYLON LOCK NUTS.

REFER TO MAN505

PLACE THE FOUR 5 INCH., 7 ½ INCH AND 10 INCH HEIGHT

ADAPTERS INTO PLACE INTO THE HEIGHT ADAPTER BRACKETS.

SHIMMING THE POST

LEVEL THE POST BY INSERTING THE SUPPLIED SHIMS UNDER

THE POST FOOTING AROUND THE WEJ-IT ANCHOR. THE LIFT

MUST BE LEVEL BOTH FRONT TO REAR AND SIDE TO SIDE. A

LEVELING DEVICE AND A MEASURING TAPE MUST BE USED.

REFER TO FIGURES 5 & 6

.

•

LEVEL THE MAIN SIDE POST FRONT TO REAR AND SIDE-TO-

SIDE USING A BUBBLE LEVEL.

•

LEVEL THE OFF SIDE POST FRONT TO REAR USING A

BUBBLE LEVEL. SET THE POST PARALLEL TO THE MAIN

SIDE POST USING A MEASURING TAPE, MEASURING FROM

THE EDGE OF THE MAIN SIDE CHANNEL TO THE EDGE OF

THE OFF SIDE CHANNEL AT THE BASE AND AT THE TOP OF

THE POST.

•

THE MEASUREMENT AT THE TOP OF THE POST MUST BE

THE SAME AS THE MEASUREMENT AT THE BASE OF THE

POST.

AT THIS TIME PERFORM THE PRE-OPERATION CHECK LIST AND

MAINTENANCE PROCEDURES (DAILY - WEEKLY - MONTHLY)

MAKE ALL ADJUSTMENTS PERTAINING TO THESE PROCEDURES.

DIVERTER VALVE OPERATION

WARNING

AS WITH ALL FUNCTIONS OF THE LIFT UNIT, NEVER OPERATE

THE DIVERTER VALVE UNLESS YOU HAVE FIRST PERFORMED

THIS OPERATION WITH NO VEHICLE, AND FULLY UNDERSTAND

ITS FUNCTIONS.

BOTH MECHANICAL SAFETIES MUST BE ENGAGED BEFORE

OPERATING THE DIVERTER VALVE.

PURPOSE

•

THE PURPOSE OF THE DIVERTER VALVE IS TO ENABLE THE

OPERATOR TO RAISE OR LOWER THE OFF SIDE CARRIAGE

INDEPENDENTLY OF THE MAIN SIDE CARRIAGE.

TO OPERATE THE DIVERTER VALVE

ENGAGE THE DIVERTER VALVE BY PULLING DOWN ON THE

DIVERTER VALVE PULL KNOB.

REFER TO MAN504

•

THIS WILL DIVERT ALL FUNCTIONS OF THE POWER UNIT TO

THE OFF SIDE CYLINDER.

WITH THE VALVE ENGAGED, ENERGIZE THE POWER UNIT BY

PUSHING THE UP BUTTON.

WHEN THE DESIRED HEIGHT HAS BEEN ACHIEVED, RELEASE

THE DIVERTER VALVE PULL KNOB AND THE UP BUTTON.

PULLING DOWN ON THE LOWERING HANDLE, LOWER THE UNIT

ONTO BOTH MECHANICAL SAFETIES ENDING THIS PROCEDURE.

Summary of Contents for LMF-12

Page 26: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 19 Figure 1 ...

Page 27: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 20 Figure 2 ...

Page 28: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 21 Figure 3 ...

Page 29: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 22 Figure 4a ...

Page 30: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 23 Figure 4b ...

Page 31: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 24 Figure 5 ...

Page 32: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 25 Figure 6 ...

Page 33: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 26 Figure 7 ...

Page 34: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 27 Figure 8 ...

Page 35: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 28 Figure 9 ...

Page 36: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 29 Figure 10 ...

Page 37: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 30 Figure 11 ...

Page 38: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 31 Figure 12 ...

Page 40: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 33 ...

Page 41: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 34 ...

Page 42: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 35 ...

Page 43: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 36 ...

Page 44: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 37 ...

Page 45: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 38 ...

Page 46: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 39 ...

Page 47: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 40 ...

Page 48: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 41 ...

Page 49: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 42 ...

Page 50: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 43 ...

Page 51: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 44 ...

Page 52: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 45 ...

Page 53: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 46 ...

Page 55: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 48 ...

Page 56: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 49 ...

Page 57: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 50 ...

Page 58: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 51 ...

Page 59: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 52 ...

Page 60: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 53 ...

Page 61: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 54 ...

Page 62: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 55 ...

Page 63: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 56 ...

Page 68: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 61 ...

Page 69: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 62 ...

Page 70: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 63 ...

Page 71: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 64 ...

Page 72: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 65 ...

Page 73: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 66 ...

Page 74: ...MOHAWK MODEL LMF 12 TP 15 TP 16 TP 18 67 ...