MoJack 750XT Lift

19

Maintenance Schedule

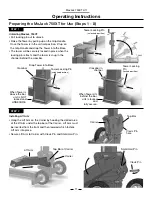

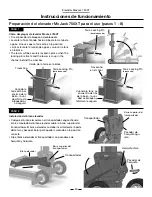

• Before each use, always check for any worn, loose or

damaged parts on the MoJack 750XT. If any damaged parts

are present, do not use the MoJack 750XT and contact

MoJack at 1-877-575-3173.

• Clean and oil the screw thread after every 50 uses or at

least once a year using light machine oil.

• Place lithium grease between the Crank Handle Base and

the brass bearing after every 50 uses or once a year.

Without weight on carrier, lift the Crank Handle to create

a small gap between the brass bearing and the Crank

Handle Base. Use a small brush to apply the lithium

grease between the two surfaces.

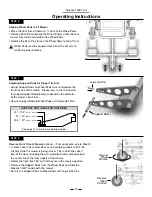

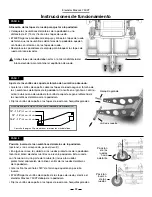

• Place lithium grease on or around Screw Thread Bottom,

Roll Pin and Screw Thread Bottom Washer after every 50

uses or at least once a year.

• Spray grease or lube in Locking Pin holes and shaft after

every 50 uses or at least once a year.

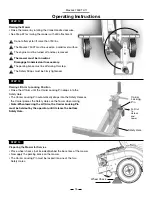

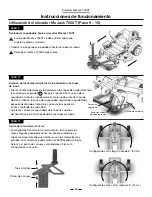

• (Optional) Check for Carrier Locking Pin operation. Turn

top Crank Handle to raise the Lift Arm to the first Safety

Hole and listen for click as pin pops into hole. After a

click is heard, reverse direction of Crank Handle rotation

without pulling on the Carrier Locking Pin ring. Pin

should hold Carriage at height.

Do not force the handle

past the lock point, as this may damage the Screw

Thread.

If Carrier Locking Pin does not hold Lift Arm

height, do not use the MoJack 750XT and contact MoJack

at 1-877-575-3173. After checking Carrier Locking Pin

operation, proceed to lower by pulling out on the Carrier

Locking Pin ring.

Screw Thread

Brass Bearing

Crank Handle Base

Pull Out

to Lower

Screw Thread Bottom

Screw Thread

Bottom Washer

Roll

Pin

Tower Locking Pin

Safety Hole

Carrier

Locking

Pin