Section 4 - Overview

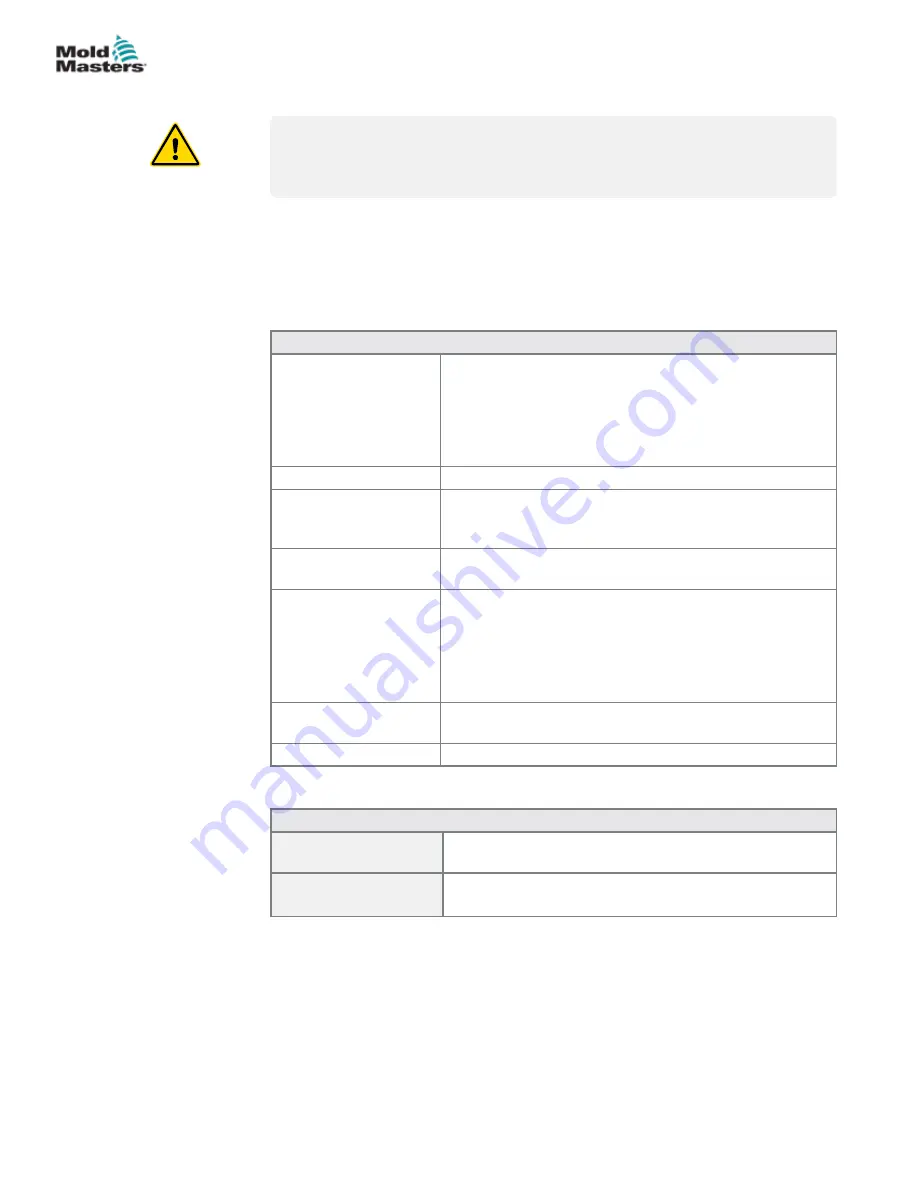

WARNING

Ensure that you have fully read “Section 3 - Safety” before setting up or

operating the E-Drive controller.

4.1

Specification

The following are general specifications. The supplied E-Drive may have

contractual variations and differ in some options.

4.1.1 Cabinet

Table 4-1 Cabinet Information

Supply Voltage and

Current Rating

380-480vac, 50/60 Hz, 3 phase delta (Neutral not

required), Maximum of 20A per phase.

Refer to the serial plate on the controller cabinet for

confirmation of the supply requirements for your model.

If the local supply is outside the specified range please

contact

Mold-Masters

office for advice.

Voltage Bandwidth

Stable within

±

20% supply voltage swing

Over Current Unit

Protection

Rear-mounted Miniature Circuit Breaker gives over

current protection and may also be used as a lockable

main isolator

Input from Associated

Controller

A HAN4A connector accepts an “Up to heat” signal which

is required before the E-Drive is operable

I/O Connection and

Alarm Channel

HAN10E has the following functions

“E-Drive ready” output

Accepts incoming trigger(s) to operate E-Drive from a dry

contact or an external 24V source.

Isolated closing contact to give a common alarm output

signal

Servo Output Cables

Non-detachable cables provided as one pair per servo

drive

Cabinet Size (in mm)

448 (D) x 350 (W) x 500 (H)

4.1.2 Pendant

Table 4-2 Pendant Information

Emergency Shutdown

Button

Latching push-to-operate and turn-to-release button.

Hot Runner Controller

Interface

LCD Touch Screen for HMI

4.2 Future Expansion

The E-drive unit has been designed to give years of service and has the

ability to receive firmware updates, to allow newly developed features to be

easily added as they become available.

4-1

OVERVIEW

E-Drive Controller User Manual (with Pendant HMI)

© 2020 Mold-Masters (2007) Limited. All Rights Reserved.

Summary of Contents for E-Drive Series

Page 1: ...version 3 User Manual with Pendant HMI Original Instructions ...

Page 2: ......

Page 26: ......

Page 36: ......