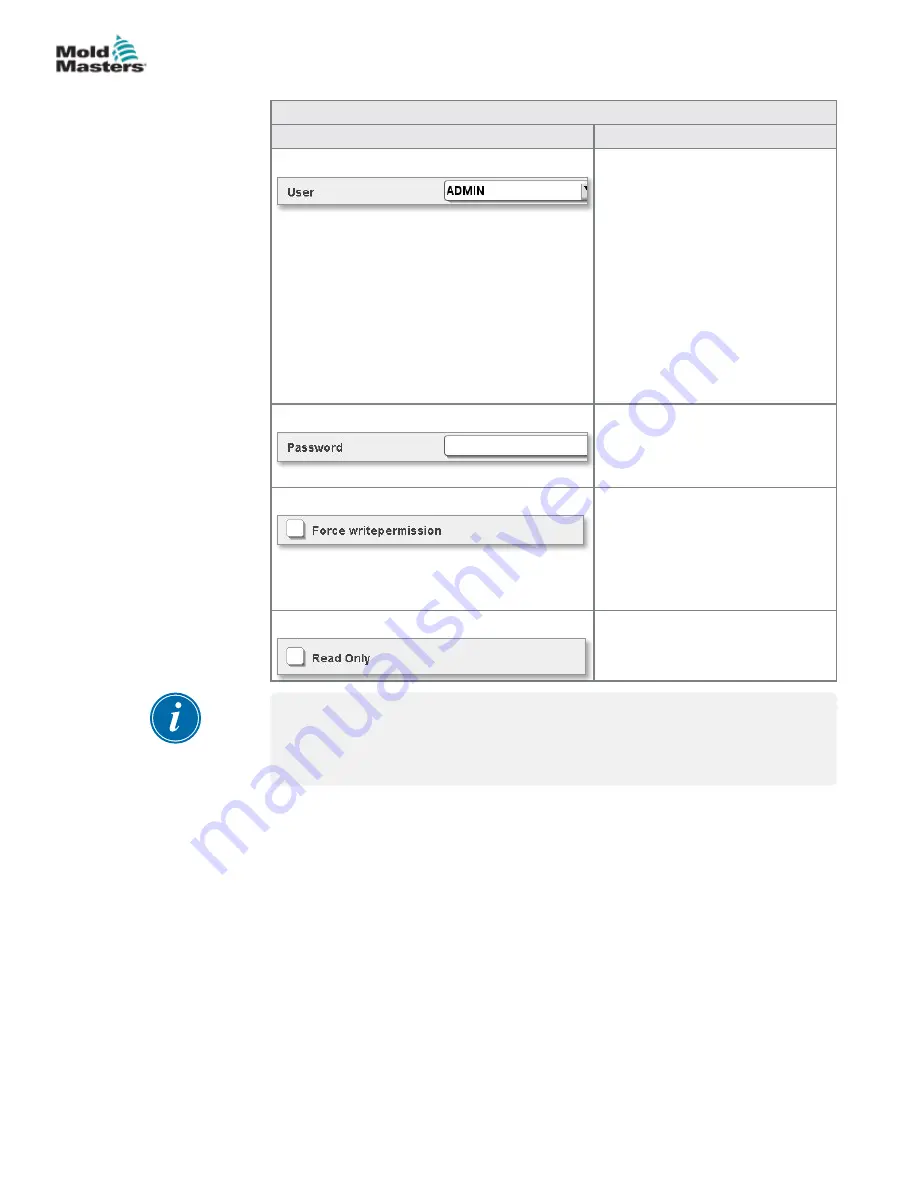

7.2.2 Description of the Elements

Input field / Check box

Description

User

Users that are registered

by the Administrator can be

selected from a drop down list.

After entering the correct

password and pressing

Login, the user is logged in. A

language or unit change-over

may occur.

By pressing the Logout

button the current user is

logged out and the user level

automatically returns to 1.

Password

This field is used to enter the

user password (the type of

input panel can be selected in

the HMI configuration).

Force Write Permission

By selecting this check box, the

write permission can be forced

if the maximum number of

sessions with write permission

on the system has been

reached.

Read only

If this check box is selected,

the login is made without write

permission.

NOTE

When logging in via chip card (RFID) the login dialog is not displayed, as

the necessary data, including the password, are read directly from the chip

card.

7-4

E-Drive Controller User Manual (with Pendant HMI)

SCREEN FUNCTIONALITY

© 2020 Mold-Masters (2007) Limited. All Rights Reserved.

Summary of Contents for E-Drive Series

Page 1: ...version 3 User Manual with Pendant HMI Original Instructions ...

Page 2: ......

Page 26: ......

Page 36: ......