www.moldex.com

TESTING ACCORDING TO EN 149:2001 + A1:2009

Total inward leakage

Ten test subjects perform a variety of exercises. During the exercises the amount

of test aerosol that penetrates the fi lter, face seal and valve are sampled. The

total inward leakage of 8 out of 10 test subjects shall not exceed the following

levels:

The fi lter penetration after loading the fi lter with 120 mg paraffi n oil according

to DIN EN 149:2001 + A1:2009 shall not exceed the following levels:

Flammability

4 respirators are passed through a 800°C (+/- 50°C) fl ame with a speed of 6 cm/s.

After passing through the fl ame the respirator has to self-extinguish.

Breathing Resistance

The breathing resistance produced by the fi lter of the respirator is tested at an airfl ow of

30 l/min and 95 l/min.

INS TRUCTIONS FOR USE

· The user has to be trained and instructed in wearing the mask.

· FFP masks do not protect against gases and vapours.

· The oxygen concentration of the ambient atmosphere should be at 19,5 % Volume.

· These respirators may not be used if the concentration type, and properties of

contaminants in the ambient atmosphere are unknown or at dangerous levels.

· Respirators should be disposed if damaged, if the breathing resistance

be comes high due to clogging.

· Never tamper with, alter or modify the respirator.

INS TRUCTIONS FOR FITTING

EU - 0

1 - 20

10

/ 02

Datasheet

FFP masks

Protection against Dust, Mist & Fumes

Category

max. breathing resistance

30 l / min

95 l / min

FFP3

1,0 mbar

3,0 mbar

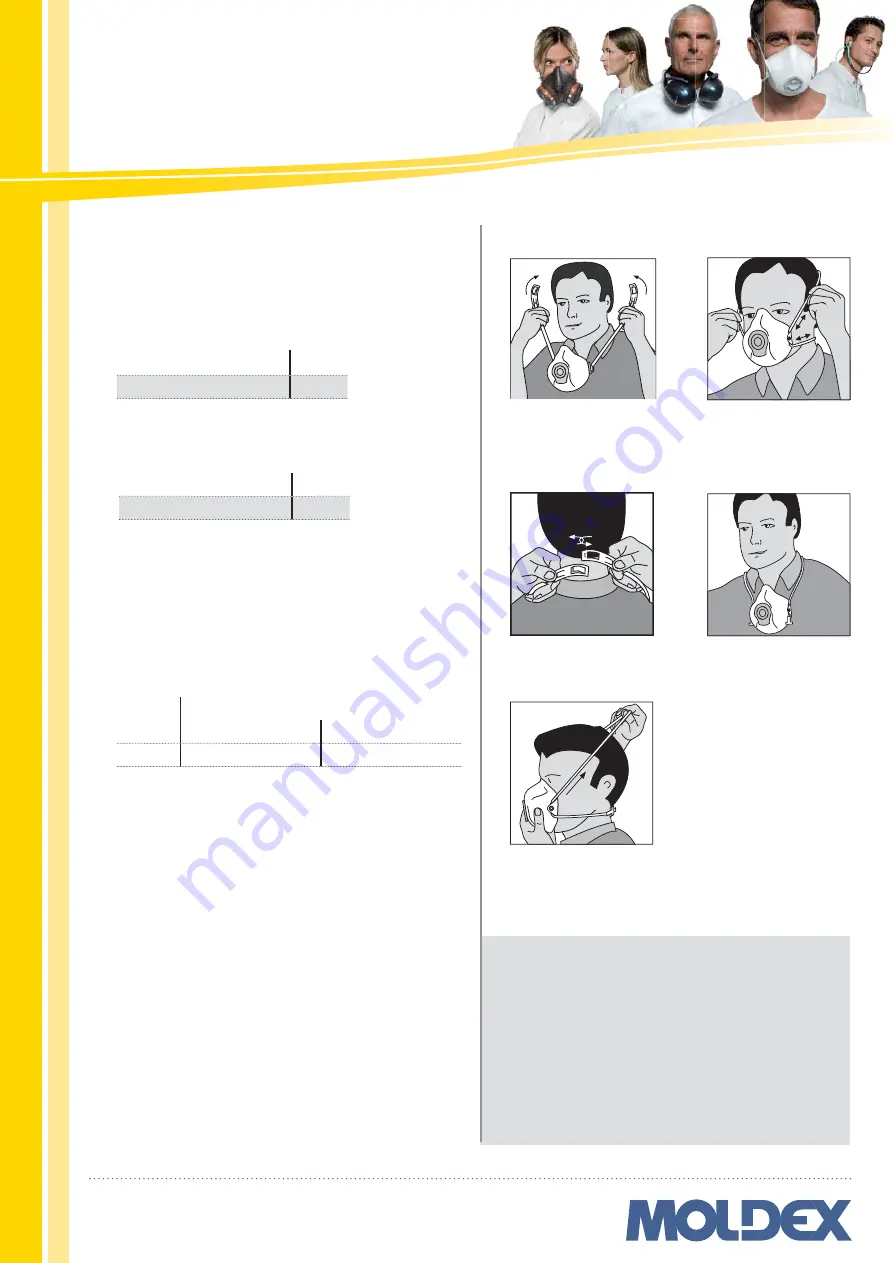

1.

2. Fasten the two pieces buckles

at the back of the neck.

3. Place respirator on chin and

lift upper strap to place on

back of neck.

4. Ensure respirator fits secure

and comfortable. To fasten

respirator pull strap at either

side of the buckle.

5. Unbuckle to take off. During

work breaks open the buckles

and let the mask hang around

the neck.

Category

FFP3

max. total inward leakage

2 %

Category

FFP3

max. Filter penetration

1 %

INFO

For help on selection and training please

contact us. We offer a wide range of training

packages and support material.

MOLDEX-METRIC AG & Co. KG

Tübinger Straße 50

72141 Walddorfhäslach

Germany

Tel.: +49 (0) 71 27/81 01-02

Fax: +49 (0) 71 27/81 01-48

info@moldex-europe.com

www.moldex-europe.com