Tool Kit for 250 MP-Lock Terminal

Doc No: ATS-6382355HM Release Date: 03-09-11

UNCONTROLLED COPY

Page 3 of 9

Revision: A

Revision Date: 03-09-11

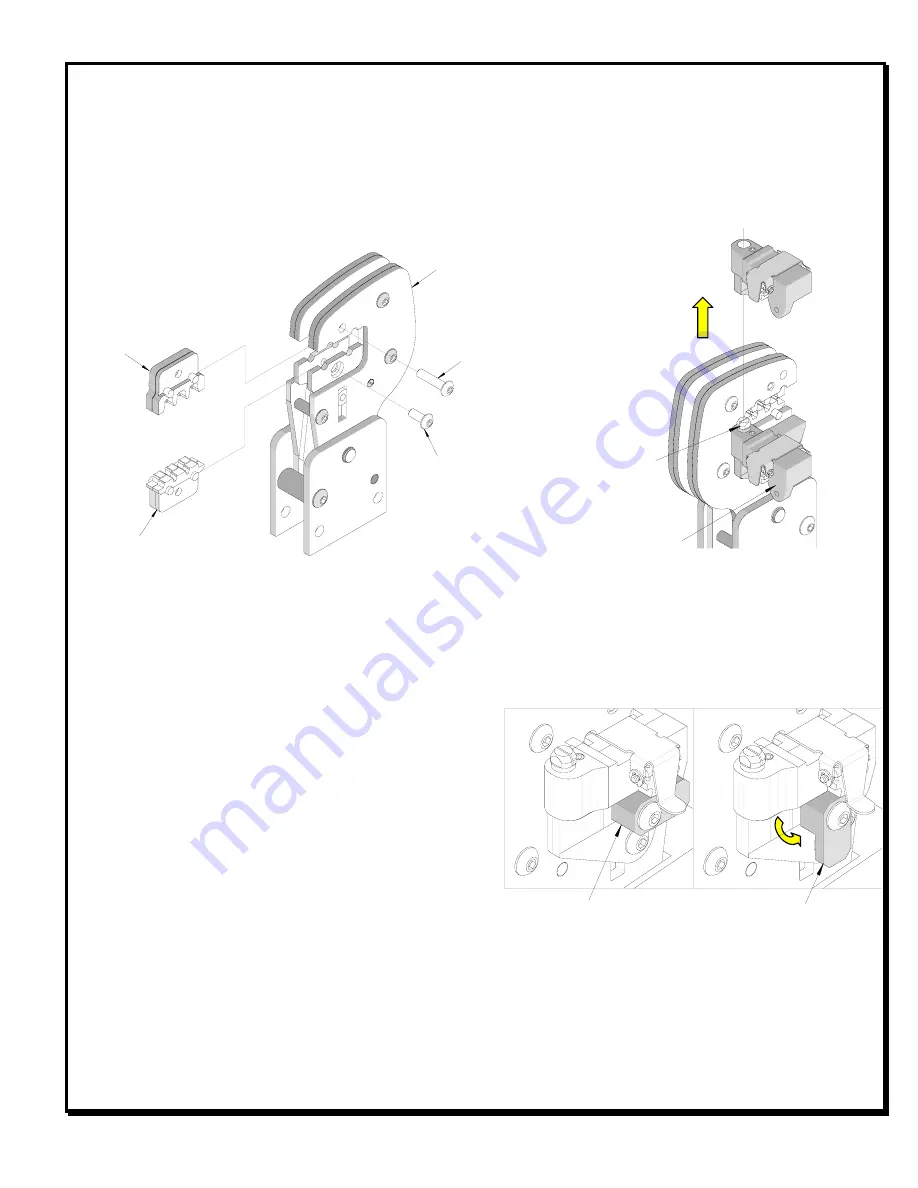

ANVILS

POWER

CRIMP

HEAD

Figure 1

PUNCHES

M4 X 10 LONG

BHCS

M4 X 18 LONG

BHCS

SWING

LOCATOR

OPEN

PRESS DOWN

ON THE BRASS

PIVOT SHAFT

LIFT UP ON

THE LOCATOR

Figure 2

To install the locator

1.

Position the locator with the hole over the brass pivot shaft and snap it into place.

To remove the locator

1.

Open the crimp hand tool.

2.

Swing the existing locator open and away from the hand tool.

3.

Firmly press down on the brass pivot shaft with your thumb, while pulling the locator up. Slip the locator off the

top of the brass pivot shaft.

OPERATION

Open the tool by squeezing the handles together, at the end of the closing stroke, the ratchet mechanism will

release the handles, and the hand tool will spring open.

Crimping Terminals

1.

Select the desired terminal listed in the preceding

charts.

2.

Turn the Locator Lock Latch down to unlock. See

Figure 3.

3.

Swing the terminal locator away from the crimp tool

shown in Figure 4. Some terminals with large

insulation grips may interfere with the crimp tooling

when swinging the locator into position. The terminal

must then be loaded into the locator in the

closed/crimp position. See Figure 5.

4.

Press down on the wire stop on the locator as shown

in Figure1. Insert the proper terminal into the proper

nest opening. Make sure when choosing the nest opening, it will correspond with the A, B or C profile on the

hand tool.

5.

Return the locator to its original position.

6.

Turn the Locator Lock Latch up to lock. Make sure that the terminal is visually centered over the punch.

Figure 3

LATCH LOCKED

LATCH UNLOCKED