Hand Crimp Tool For

3.50 (.138”) Wire to Wire Connector, Crimp Pin

Doc No: ATS 638238700

Release Date: 07 13 11

Page 4 of 7

Revision: A

Revision Date: 07 13 11

+ /! &

<

%

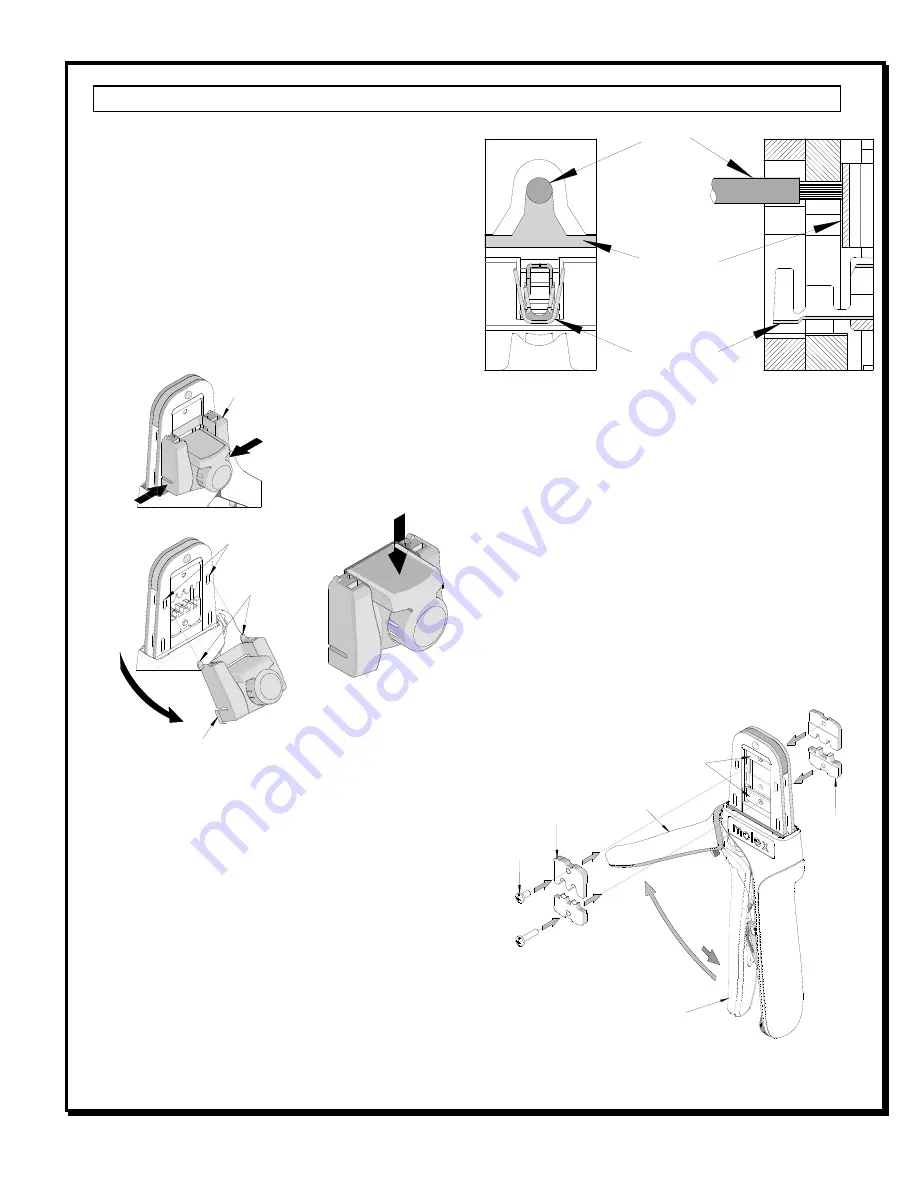

Note: The tamper proof ratchet action will not release the tool until it has been fully closed.

8. Remove the crimped terminal from the terminal

locator by pulling on the wire.

9. Visually inspect the crimped terminal for proper

crimp location.

10. On some large O.D. wires, it may not be possible to

insert the wire with the tool partially closed. Those

wires should be inserted with the hand tool in the

open position. Insert the wire above the terminal in

the punch and against the wire stop then close the

tool. See Figure 6.

!

,

See the parts list on the last page of this document for

the proper locator order number. Follow the steps

below to replace the locator.

1. Open the crimp hand tool.

2. Squeeze gently on the lower area shown in

Figure 7A with your thumb and index finger.

The lower tabs of the locator should disengage

from the hand tool.

3. Lift and pull away from the hand tool. The top

locator hooks should slip out of the top slots

easily. See Figure 7A.

4. To reinstall the new locator, make sure the hand

tool is in the open position.

5. Press the red insert down as far as it will go as

shown in Figure 7B.

6. Holding onto the lower part of the locator with your

thumb and index finger, insert the locators top

hooks (2) into the hand tool top slots.

7. Rotate the locator down and press the lower tabs

into the two bottom slots of the hand tool. To

secure the locator into place, the lower tabs must

snap into place on the hand tool frame.

+ /! $

:

;

:

;

+ /! )

7

+

+ /! 1

:

;

+ /! )