Hand Crimp Tool For

3.50 (.138”) Wire to Wire Connector, Crimp Pin

Doc No: ATS 638238700

Release Date: 07 13 11

Page 6 of 7

Revision: A

Revision Date: 07 13 11

+ /! 1'

:

;

7

8

?

"@/-

!

"

0

+ /! 1'2

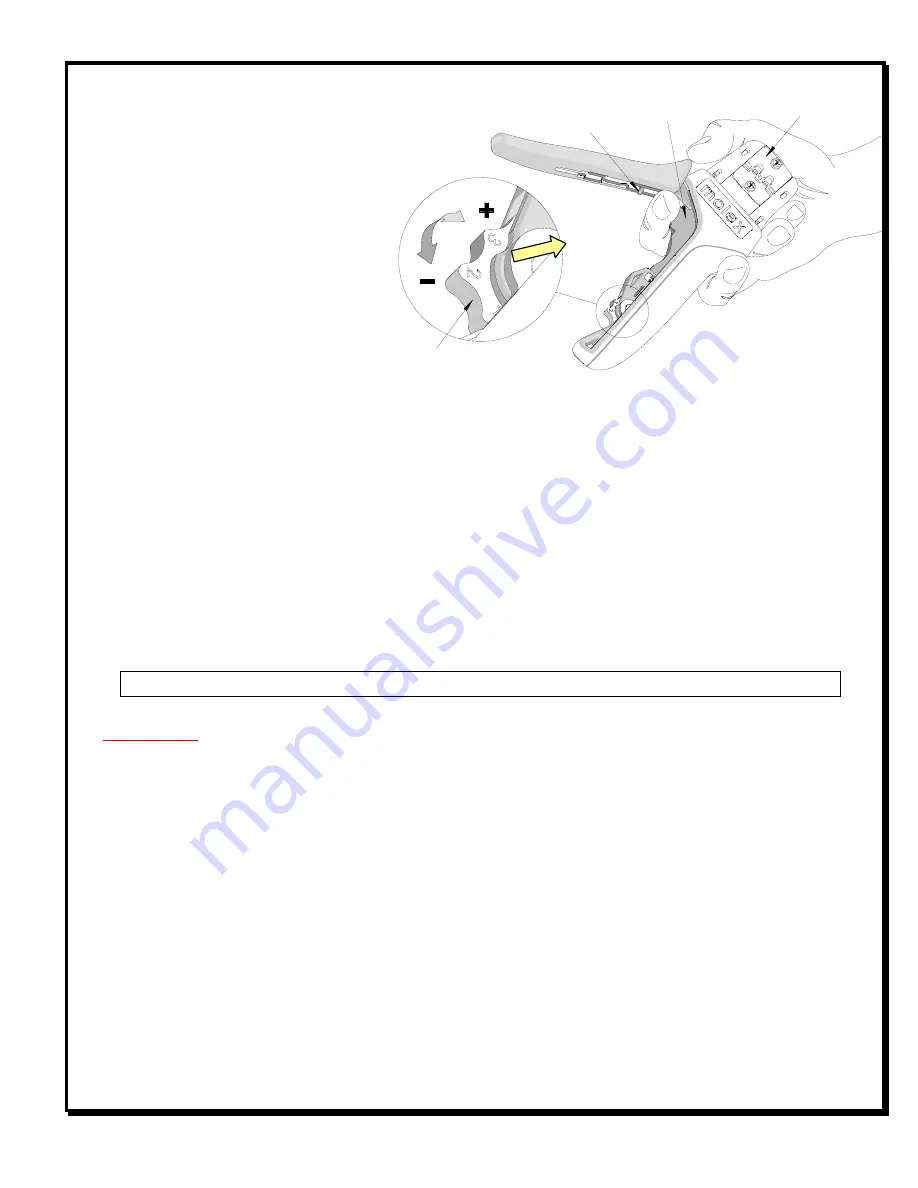

This hand tool is factory preset to 25 45

LBS. preload. It may be necessary over

the life of the tool to adjust tool handle

preload force. Listed below are the steps

required to adjust the crimping force of the

hand tool to obtain proper crimp

conditions:

1. Hold the hand tool in the palm of your

hand as shown in Figure 10. Using

the index finger squeeze the link

towards the top of the hand tool

frame. This will release the preload

adjustment wheel.

2. Rotate the setting wheel counter clockwise (CCW) to increase handle force. The numbers will display higher.

To decrease handle force rotate the setting wheel clockwise (CW).

3. Release the link to lock the setting wheel in place.

4. Check the crimp specifications or conduct a pull test after tool handle preload force is adjusted.

!!

A

This tool is for electrical terminal crimping purposes only. This tool is made of the best quality materials. All vital

components are long life tested. All tools are warranted to be free of manufacturing defects for a period of 30

days. Should such a defect occur, we will repair or exchange the tool free of charge. This repair or exchange will

not be applicable to altered, misused, or damaged tools. This tool is designed for hand use only. Any clamping,

fixturing, or use of handle extensions voids this warranty.

: Molex crimp specifications are valid only when used with Molex terminals and tooling.

5

1. Manually powered hand tools are intended for low volume or field repair. This tool is

NOT

intended for

production use. Repetitive use of this tool should be avoided.

2. Insulated rubber handles are not protection against electrical shock.

3. Wear eye protection at all times.

4. Use only the Molex terminals specified for crimping with this tool.

!

Molex does not certify or re certify hand tools but rather supplies the following guidelines for customers to re certify

hand tools.

%

This tool is qualified to pull force only. See the Molex web site for the Quality Crimp Handbook for more

information on pull testing.

%

If the tool does not meet minimum pull force values, handle preload should be increased and the pull test

rerun, (See How to Adjust Preload).

%

When the hand tool is no longer capable of achieving minimum pull force, it should be taken out of service and

replaced.