Hand Crimp Tool For Quick Disconnect, Female Terminals

Doc No: ATS-638252800

Release Date: 09-12-12

UNCONTROLLED COPY

Page 2 of 7

Revision: A

Revision Date: 09-12-12

CONDITIONS:

After crimping, the conductor profiles should measure the following.

Terminal

Series No

Wire Size

Conductor Crimp

▲

Insulation Crimp

Pull Force

Minimum

Profile

Height

Width Maximum

Height (Ref.)

Maximum

Width (Ref.)

Maximum

AWG mm

2

mm

In.

mm

In.

mm

In.

mm

In.

N

Lb. 18 20

94030

20

0.5

1.30 – 1.40 .051-.055

2.30

.091

3.10

.122

3.50 .138

78.4 17.6

X

18

0.8

1.40 – 1.50 .055-.059

2.30

.091

3.15

.124

3.50 .138 117.6 26.4 X

1.0

1.45 – 1.55 .057-.061

2.30

.091

3.20

.126

3.50 .138 156.8 35.2 X

Tool Qualification Notes:

1. Pull Force should be measured with no

influence from the insulation crimp.

2. The above specifications are guidelines

to an optimum crimp.

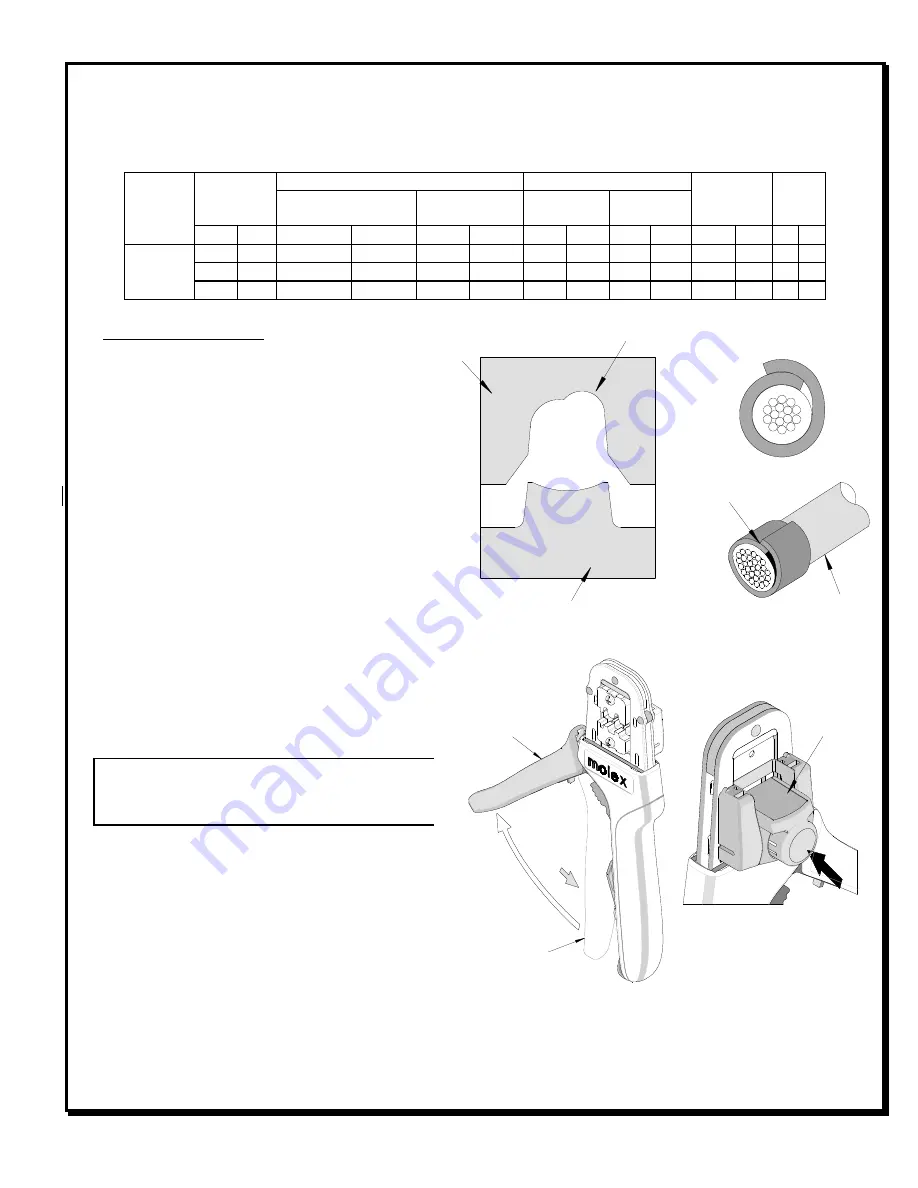

▲

Insulation Crimp Note

:

Due to the terminal’s insulation grip design

and/or insulation diameter range, this tool

uses “overlap” form geometry in the

insulation punch. This produces an overlap

insulation crimp (A620 – compliant). While

the insulation punch profile may appear

“lopsided”, this is a normal condition for this

tool. See figure to the right. (Some tools with

multiple crimp pockets may not have the “overlap”

profile on all pockets).

OPERATION

CAUTION:

Install only Molex terminals listed

above with this tool. Do not crimp hardened

objects as damage can occur to the tool or die.

Open the tool by squeezing the handles together.

At the end of the closing stroke, the ratchet

mechanism will release the handles and the hand

tool will spring open. See Figure 1.

Crimping Terminals

1.

Select the desired terminal listed in the

preceding charts.

2.

Make sure the center of the locator is in the down position. With the locator attached, push the locator button

on the back of the hand tool to bring the locator forward through the tooling. See Figure 2.

LOCATOR

IN DOWN

POSTION

PUSH ON THE

LOCATOR BUTTON

Figure 2

SQUEEZE

HANDLES

TOGETHER

HANDLE WILL

SPRING OPEN

Figure 1

OVERLAP

INSULATION

CRIMP

OVERLAP FORM GEOMETRY

ANVIL

PUNCH

WIRE