Tool Kit for 250 Slip-in Receptacle Terminals

Doc No: ATS-6382575HM Release Date: 05-17-13

UNCONTROLLED COPY

Page 2 of 8

Revision:A

Revision Date: 05-17-13

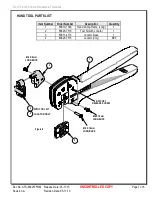

ANVILS

POWER

CRIMP

HEAD

Figure 1

PUNCHES

M4 X 10 LONG

BHCS

M4 X 18 LONG

BHCS

SWING

LOCATOR

OPEN

PRESS DOWN

ON THE BRASS

PIVOT SHAFT

LIFT UP ON

THE LOCATOR

Figure 2

CONDITIONS:

After crimping, the conductor profiles should measure the following (See notes below).

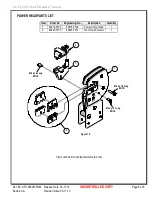

Terminal Series No.

Wire Size

Conductor Crimp

Profile

Height

Width

AWG mm

2

mm

In.

mm

In.

A B C

35725

10

5.25 2.60-2.70 .102-.106 3.70-3.90 .146-.154 X

12

3.30 2.15-2.25 .085-.089 3.70-3.90 .146-.154

X

14

2.00 1.90-2.00 .075-.079 3.70-3.90 .146-.154 X

Terminal Series No.

Wire Size

Insulation Crimp

Pull Force Minimum

Height

Width

AWG mm

2

mm

In.

mm

In.

N

Lbs

35725

10

5.25 5.10-5.30 .201-.209 4.85-5.15 .191-.203

343

77.1

12

3.30 4.80-4.95 .189-.195 4.85-5.15 .191-.203

290

65.2

14

2.00 4.50-4.65 .177-.183 4.85-5.15 .191-.203

190

42.7

Tool Qualification Notes:

1. Pull Force should be measured with no influence from the insulation crimp.

2. The above specifications are guidelines to an optimum crimp.

Note:

A crimp height chart is provided with this manual as Reference Only. Due to the wide range of wires, strands,

insulation diameters, and durometers, actual crimp height measurements may very slightly. An occasional,

destructive, pull force test should be preformed to check hand tool crimp. Pull Force value must exceed the

minimum pull force specifications listed.

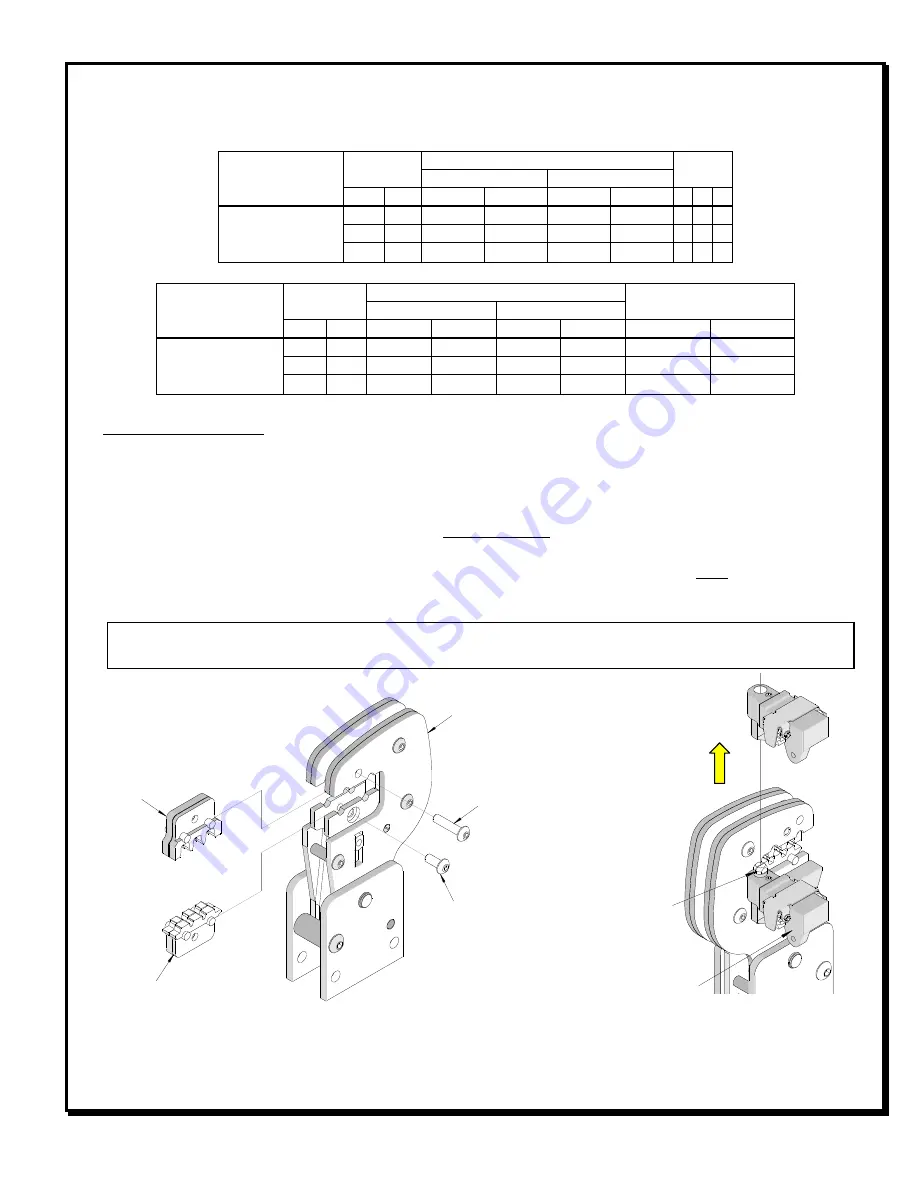

CAUTION:

Install only Molex terminals listed above with this tool. Do not crimp hardened objects as damage

can occur to the tool or die.

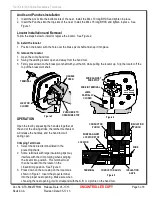

INSTALLATION

To install the Tool Kit into the Power Crimp Head follow the steps below: