Hand Crimp Tool for MX120G™Crimp Terminals

Doc No. ATS-638258000

Release Date: 03-22-13

UNCONTROLLED COPY

Page 3 of 7

Revision: A

Revision Date: 03-22-13

PRE-STRIPPED

WIRE

TERMINAL

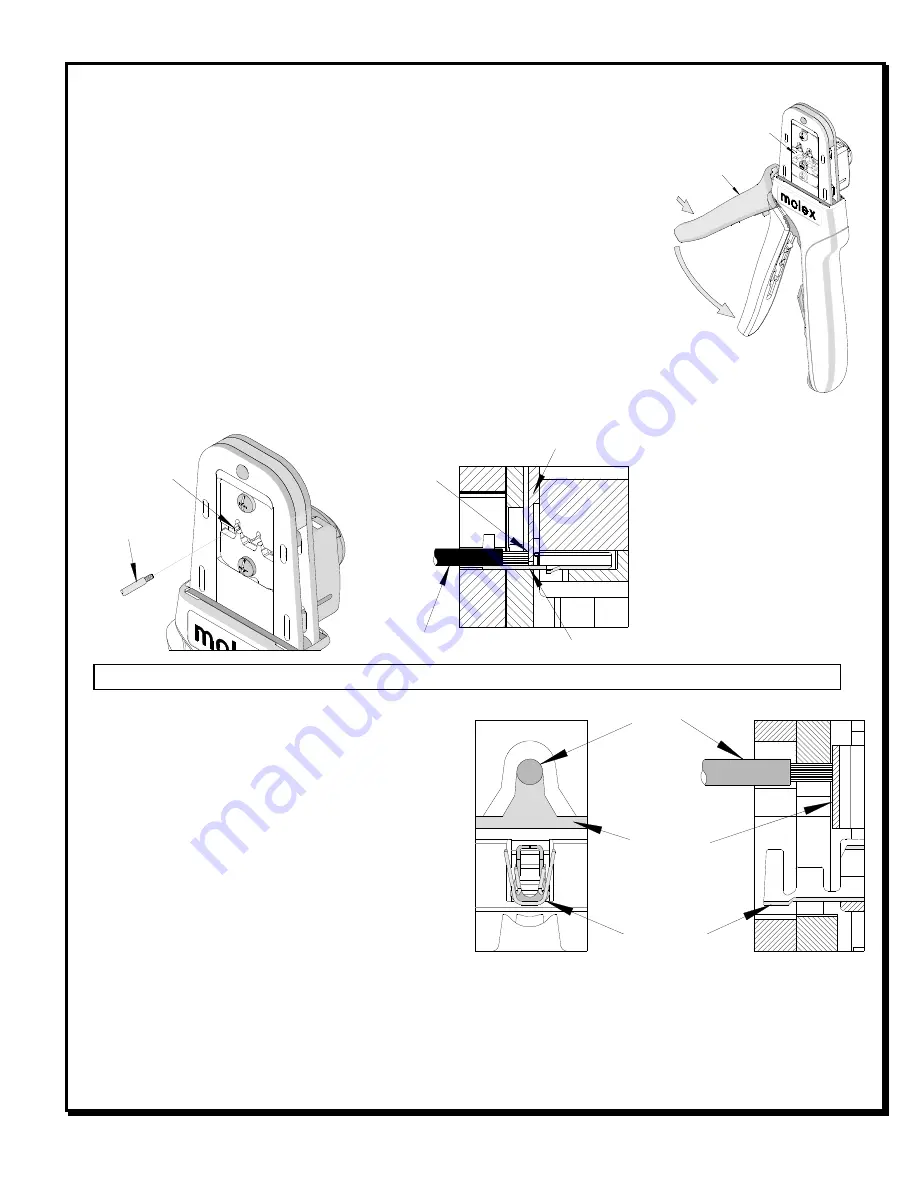

Figure 5

TERMINAL

WIRE AGAINST

THE WIRE

STOP

WIRE

WIRE STOP IS PART

OF THE LOCATOR

1.

Select the desired terminal listed in the preceding charts.

2.

Make sure the center of the locator is in the down position. With the

locator attached, push the locator button on the back of the hand tool

to bring the locator forward through the tooling. See Figure 2.

3.

While holding the locator button in, load the terminal into the proper

nest opening in the locator based on the wire gauge or terminal type

markings on the hand tooling. See Figure 3.

4.

Release the locator button, allowing the locator to return to the

crimping position.

5.

Close the tool handle until the first ratchet position engages. See

Figure 4.

6.

Insert the properly stripped wire through the terminal and against the

wire stop. See Figure 5.

7.

Crimp the terminal by squeezing the tool handles until the ratchet

mechanism cycle has been completed. Release the handles to open

the jaws.

Note: The tamper proof ratchet action will not release the tool until it has been fully closed.

8.

Remove the crimped terminal from the terminal

locator by pulling on the wire.

9.

Visually inspect the crimped terminal for proper

crimp location.

10.

On some large O.D. wires, it may not be possible

to insert the wire with the tool partially closed.

Those wires should be inserted with the hand tool

in the open position. Insert the wire above the

terminal in the punch and against the wire stop

then close the tool. See Figure 6.

Locator Replacement

See the parts list on the last page of this document for the proper locator order number. Follow the steps below to

replace the locator.

TERMINAL

Figure 6

WIRE

WIRE STOP

PARTIALLY

CLOSE HANDLE

TOOLING

PARTIALLY

CLOSED

Figure 4

FIRST RATCHET

POSITION

OPEN

POSITION