Hand Crimp Tool for 1.50mm (.059") Pico-SPOX Crimp Terminals

Doc. No: ATS-6382597HM Release Date: 05-06-13

UNCONTROLLED COPY

Page 3 of 6

Revision: B

Revision Date: 04-26-18

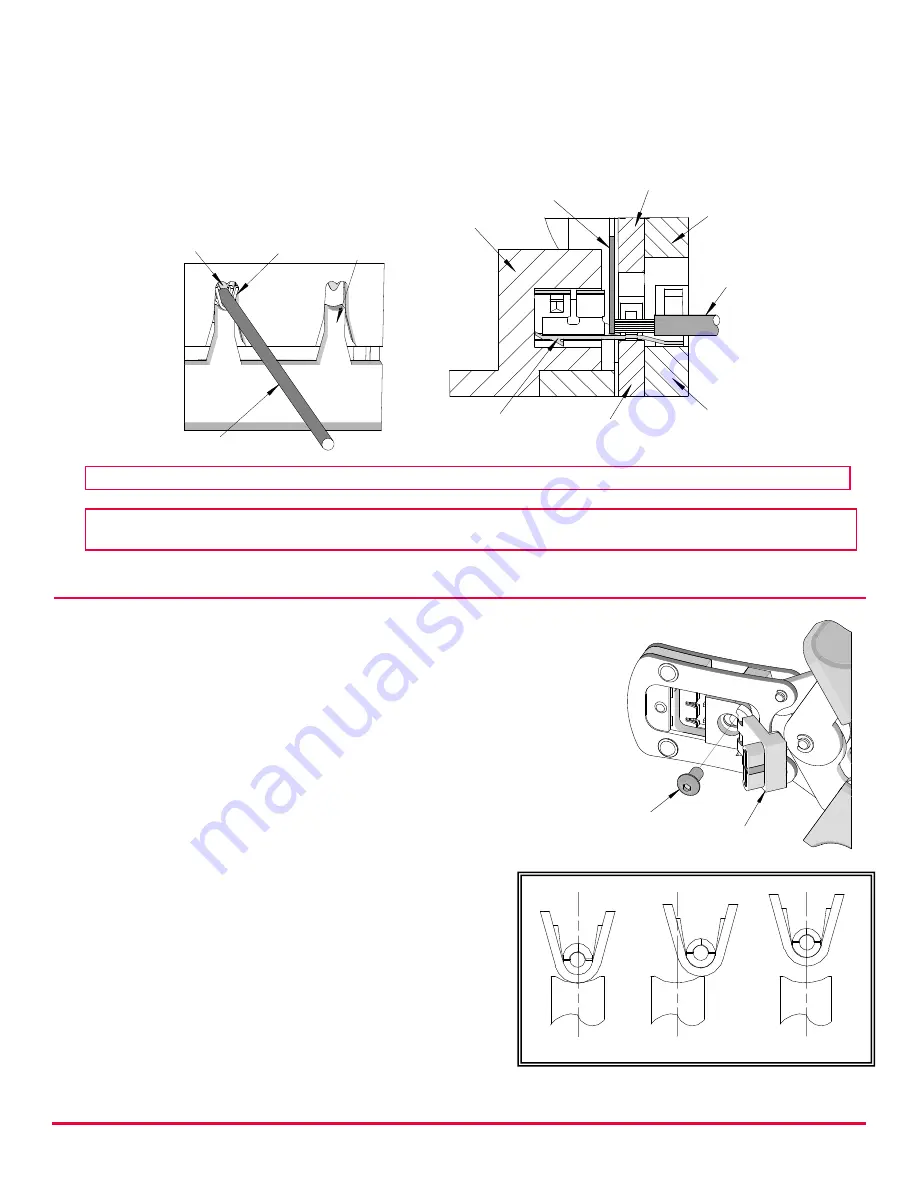

WIRE

CONDUCTOR

PUNCH

WIRE STOP

BLADE

INSULATION

PUNCH

LOCATOR

CONDUCTOR

ANVIL

INSULATION

ANVIL

TERMINAL

Figure 3

WIRE

INSULATION

ANVIL

TERMINAL

WIRE STOP

BLADE

Figure 2

5.

Slide the pre-stripped wire into the terminal. Make sure to aim the wire brush toward the tip

point on the wire stop blade. See Figure 2. Align the wire so that it is parallel and sitting

into the terminal. Maintain a light and constant pressure on the wire that is seated in the

terminal at all times. (Do not let go of the wire.) Be sure to hold the wire in place until the

terminal is fully crimped. See Figure 3.

6.

Close the tool until the ratchet releases.

7.

Lift the wire stop blade.

8.

Carefully remove the crimped terminal.

Note:

The tamper-proof ratchet action will not release the tool until it has been fully closed.

Note:

To maintain good brush control and a consistent bell mouth, the crimping instructions must

be followed.

TERMINAL LOCATOR REPLACEMENT

This section describes the procedure for changing locators.

Removal

1.

With the tool in the open position, pivot the terminal

locator outward.

2.

Remove the M4 BHCS. See Figure 4.

Installation

1.

Place the proper locator on the hand tool. Install the M4

BHCS. See Figure 4.

2.

Tighten the screw enough to hold the locator. Make sure

the locator can still float freely with hand pressure.

3.

Insert the proper terminal fully into the correct

profile slot until the terminal is fully seated and

stops. Then, gently pivot the locator closed.

4.

With hand pressure, slowly slide the locator to

the correct position. See Figure 5.

5.

Gently pivot the locator open without disturbing

the location.

6.

Hold the locator firmly in place, and slowly

tighten the M4 BHCS.

INCORRECT

Figure 5

CORRECT

INCORRECT

M4 BHCS

PIVOT

LOCATOR

Figure 4