AT7050 Air Crimp Tool Head

Doc No. 64005-0900

Release Date: 10-10-02

UNCONTROLLED COPY

Page 3 of 7

Revision: F

Revision Date: 05-11-05

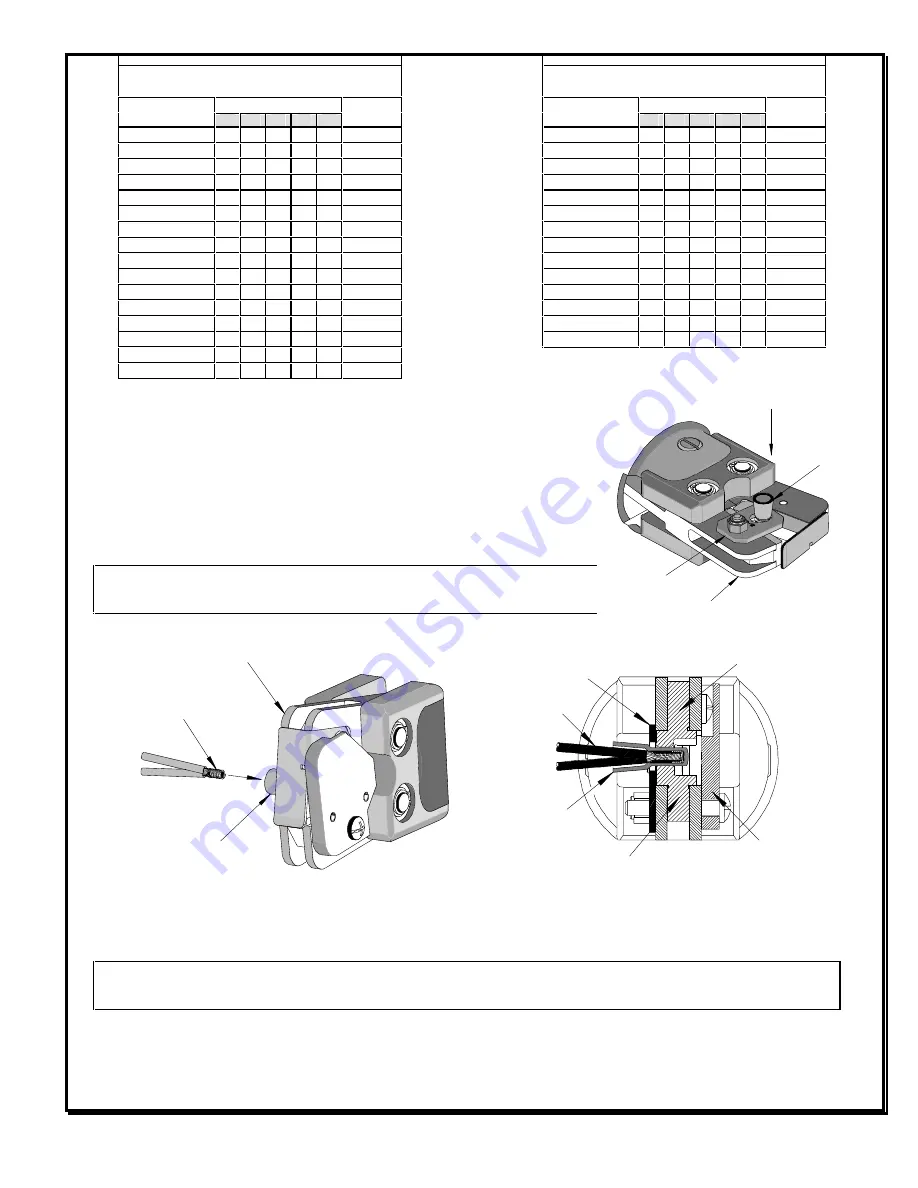

Wire Combinations for Nylon- Insulated Closed End Connectors

Part No. 191600009 (NC-2212)

Wire Gauge (AWG)

Wire Type

14

16

18

20

22

Rating

Stranded or Solid

1

1

3

UL & CSA

Stranded or Solid

1

1

4

UL & CSA

Stranded or Solid

1

2

2

UL & CSA

Stranded or Solid

1

2

3

UL & CSA

Stranded or Solid

1

3

2

UL & CSA

Stranded or Solid

6

UL & CSA

Stranded or Solid

5

UL & CSA

Stranded or Solid

5

1

UL & CSA

Stranded or Solid

4

UL & CSA

Stranded or Solid

4

1

UL & CSA

Stranded or Solid

4

2

UL & CSA

Stranded or Solid

3

UL & CSA

Stranded or Solid

3

1

UL & CSA

Stranded or Solid

3

2

UL & CSA

Stranded or Solid

3

3

UL & CSA

Stranded or Solid

2

UL & CSA

Wire Combinations for Nylon- Insulated Closed End Connectors

Part No. 191600009 (NC-2212)

Wire Gauge (AWG)

Wire Type

14

16

18

20

22

Rating

Stranded or Solid

2

1

UL & CSA

Stranded or Solid

2

2

UL & CSA

Stranded or Solid

2

3

UL & CSA

Stranded or Solid

2

4

UL & CSA

Stranded or Solid

1

1

UL & CSA

Stranded or Solid

1

2

UL & CSA

Stranded or Solid

1

3

UL & CSA

Stranded or Solid

1

4

UL & CSA

Stranded or Solid

1

5

UL & CSA

Stranded or Solid

6

UL & CSA

Stranded or Solid

5

UL & CSA

Stranded or Solid

4

UL & CSA

Stranded or Solid

3

UL & CSA

Stranded or Solid

2

UL & CSA

Crimping Terminals

1. Hold Air Head crimp tool with the locator facing up. Insert the closed end connector

in the slot (12-22). Make sure that the shoulder of the connector is resting on the

locator plate (See Figure 1).

2. Place pre-twisted wire into closed-end connector. Than press lever on air tool (See

Figure 2 and 3). Release after jaws have closed.

Caution:

Never operate this tool without the supplied safety shield in place. Never

place fingers in the tool nests.

3. Remove the crimp and inspect for proper crimp location, and check for insulation closure. Molex offers a Crimp Inspection

Handbook for closed barrel industrial product. See our website or contact your sales engineer.

Note

: Whenever crimping without the locator, make sure the seam of the terminal is oriented up or down in the tool if using

unbrazed product, as this will provide higher pull force values.

CONNECTOR

LOCATOR

JAWS OPEN

Figure 1

DROP IN THIS SIDE

Figure 2

JAWS OPEN

CONNECTOR

PRE-TWISTED

WIRE

Figure 3

LOCATOR

PRE-TWISTED

WIRE

CONDUCTOR

PUNCH

GUARD

CONNECTOR

CONDUCTOR ANVIL