AT-2214 Head Crimp Tool

Doc No: ATS-640053400

Release Date: 06-23-03

UNCONTROLLED COPY

Page 2 of 7

Revision: B

Revision Date: 09-30-05

Wire Preparation

Pre-twisted wire not required for OEM applications. For Solid wire (OEM only) strip leads to 3/8 of an inch. Insert

into connector and crimp.

For stranded wire strip leads to approximately 3/4 of an inch. Twist the wire combination even and tight. Trim

stripped pre-twisted area to 3/8 of an inch and insert into connector and crimp. For more information follow the

Quality Crimping Handbook.

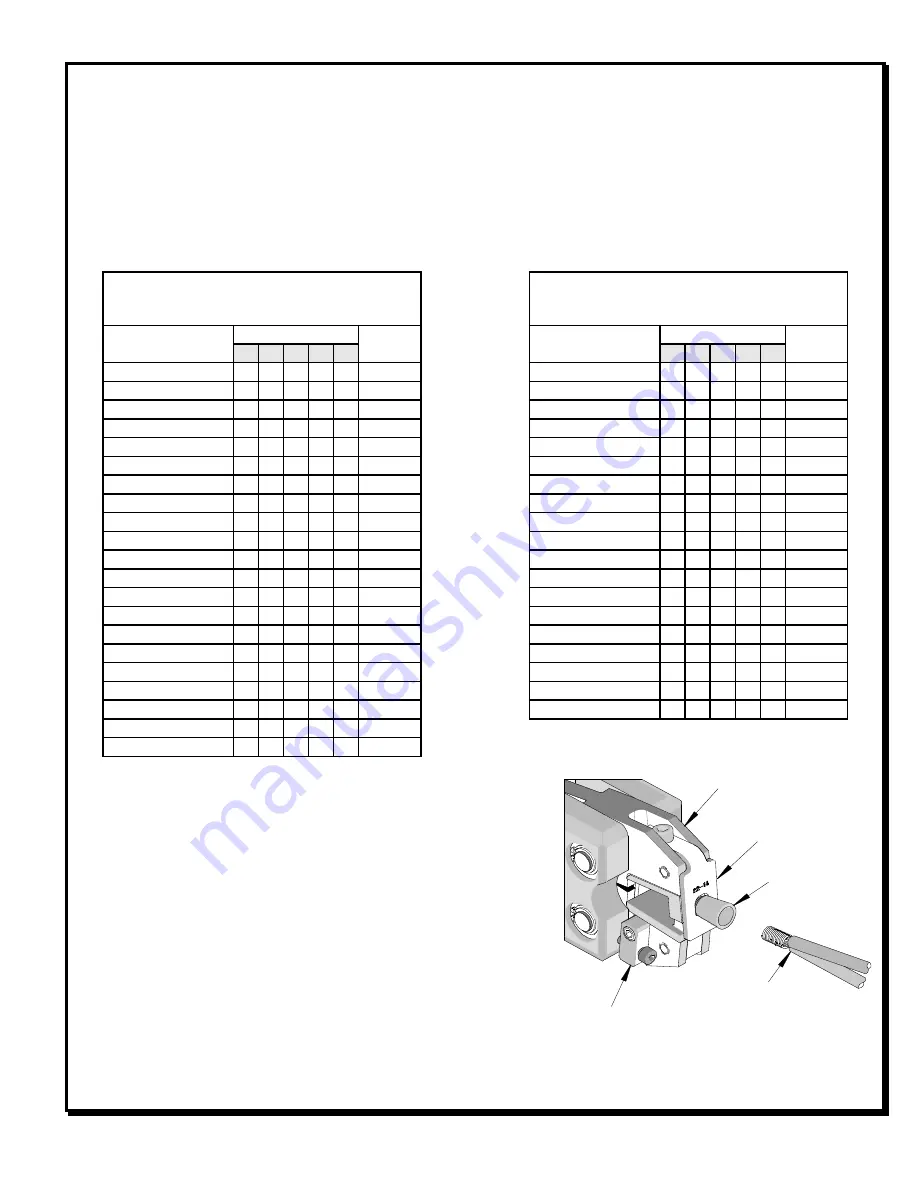

CHART 1

Wire Combinations for Nylon

Insulated Closed End Connectors

Part No. 19160001 (NC-2214)

Wire Type

Wire Gauge (AWG

)

Rating

14 16 18 20 22

Stranded only

1

1

UL only

Stranded only

1

1

1

1

UL only

Stranded only

1

2

UL only

Stranded only

1

1

UL only

Stranded only

1

3

UL only

Stranded only

1

2

UL only

Stranded only

1

1

UL only

Stranded only

3

UL only

Stranded only

2

1

UL only

Stranded only

2

2

UL only

Stranded only

2

1

UL only

Stranded only

1

3

UL only

Stranded only

1

2

UL only

Stranded only

1

2

1

UL only

Stranded only

1

1

3

UL only

Stranded only

1

1

2

UL only

Stranded only

2

UL only

Stranded only

1

1

1

UL only

Stranded only

1

5

UL only

Stranded only

1

4

UL only

Stranded only

1

3

UL only

Wire Combinations for Nylon

Insulated Closed End Connectors

Part No. 19160001 (NC-2214)

Wire Type

Wire Gauge (AWG

)

Rating

14 16 18 20 22

Stranded only

4

1

UL only

Stranded only

4

UL only

Stranded only

3

2

UL only

Stranded only

3

1

UL only

Stranded only

2

4

UL only

Stranded only

2

3

UL only

Stranded only

2

2

UL only

Stranded only

1

6

UL only

Stranded only

1

5

UL only

Stranded only

1

4

UL only

Stranded only

7

UL only

Stranded only

6

UL only

Solid only

3

UL only

Solid only

2

UL only

Stranded only

7 CSA only

Stranded only

2

4 CSA only

Stranded only

1

2

CSA only

Stranded only

2

1

CSA only

Copper Stranded only

3

CSA only

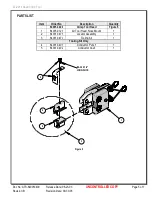

Crimping Terminals

1.

Hold air crimp tool with the locator as shown in Figure 1. Insert

the closed end connector in the locator slot. Make sure that the

shoulder of the connector is resting on the locator plate. The

connector should fit snugly into the jaws of the crimp tool. See

Figure 1.

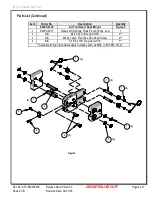

2.

If necessary, adjust the jaws of the tool in the open position so

that the connector does not move or fall out of the jaws. Using

a 3/32” Allen wrench turn the adjusting screw in the adjustment

block clockwise (CW) to close the jaws. Turn the adjusting

screw counterclockwise (CCW) to open the jaws. See Figure 2.

Figure 1

JAWS OPEN

LOCATOR

PRE-TWISTED WIRE

ADJUSTMENT

BLOCK

CONNECTOR